Semi-automatic radix adenophorae peeling machine

A peeling machine, semi-automatic technology, applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of low efficiency and high cost, and achieve the effect of high efficiency, low cost and high labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

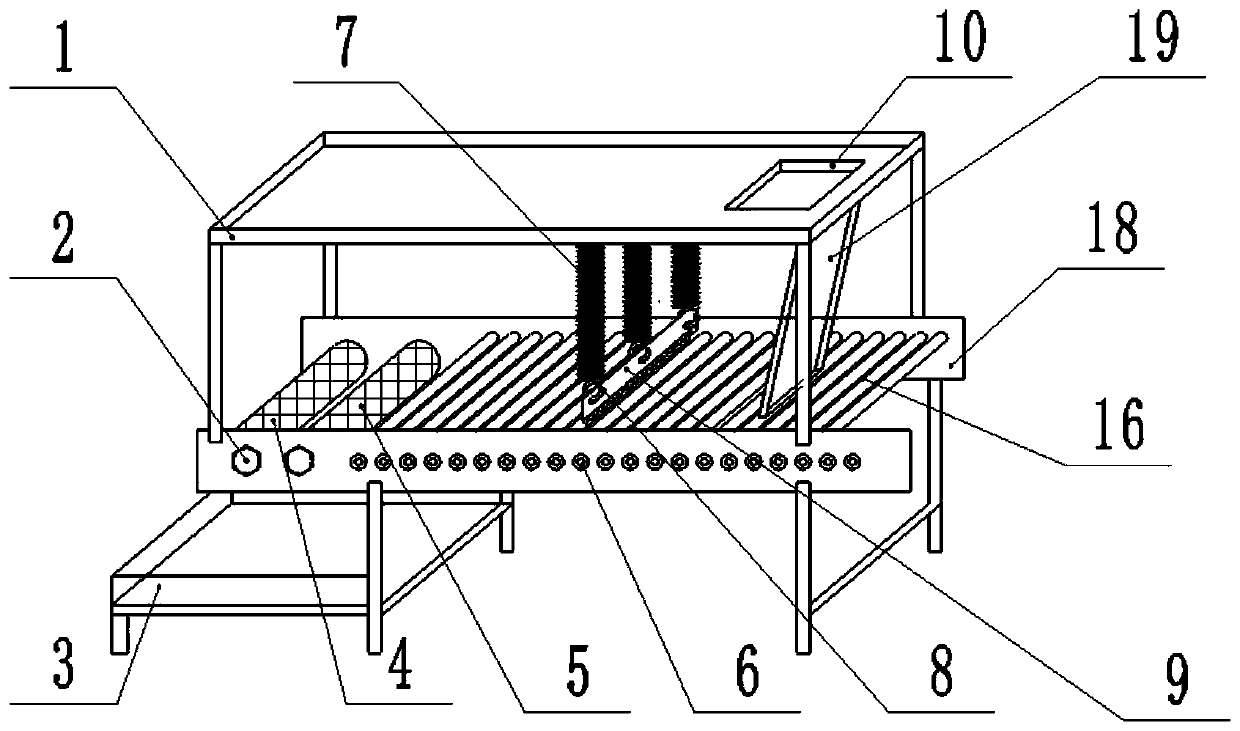

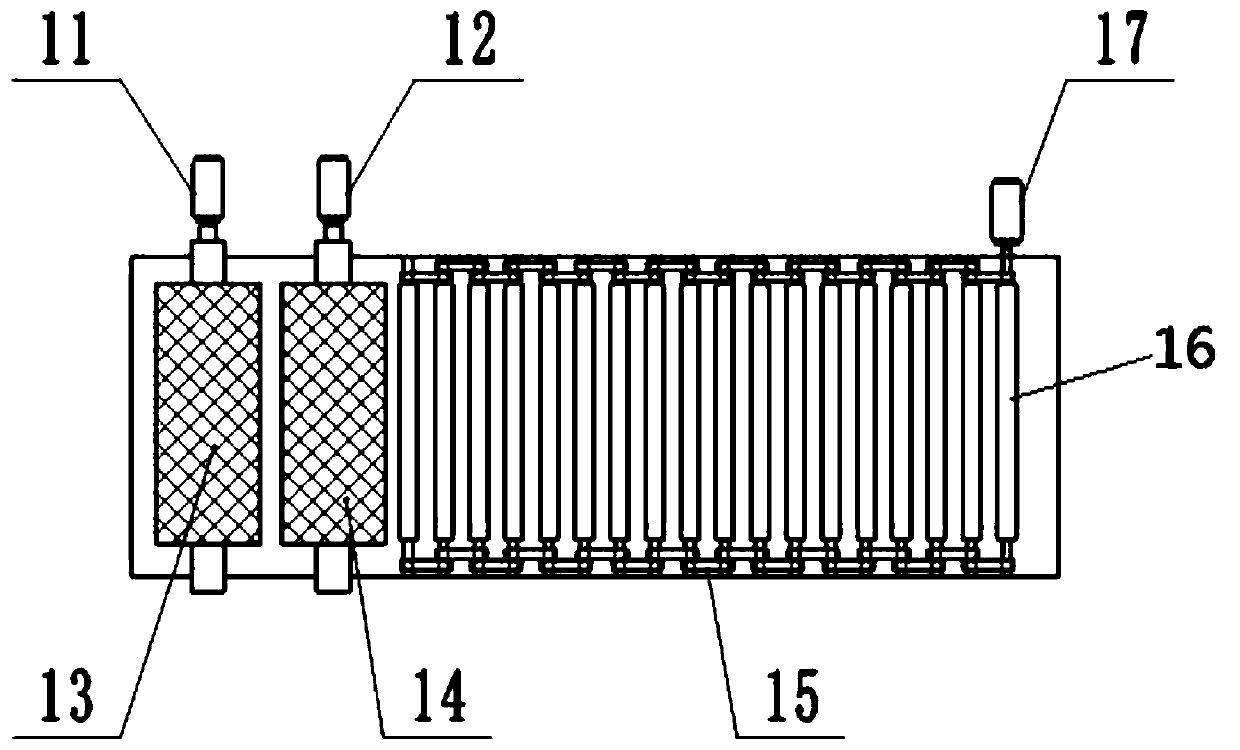

[0015] refer to figure 1 and figure 2 , a semi-automatic sand cucumber peeling machine, comprising a frame-type frame shell 1, the bottom of the frame shell 1 is connected with side plates 18 along both sides in the length direction, and a roller section and a roller section are arranged between the side plates 18; The section includes a plurality of rollers 16, and the two ends of the rollers 16 are installed on the side plate 18 through the second studs 6, and the adjacent second studs 6 are connected by a sprocket 15 for transmission, and the first roller 16 corresponds to the second Two studs 6 are connected with the output shaft of the third motor 17; the roller section includes the first roller 4 and the second roller 5, and the first roller 4 and the second roller 5 are covered with the first rubber sleeve 13, The second rubber sleeve 14, the two ends of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com