Rubber composition made from highly saturated diene elastomer and dithiosulfate

A technology of dithiosulfate and rubber composition is applied in the field of diene rubber composition for manufacturing tires, and can solve the problems of unfavorable tire rolling resistance performance, increased hysteresis of rubber composition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

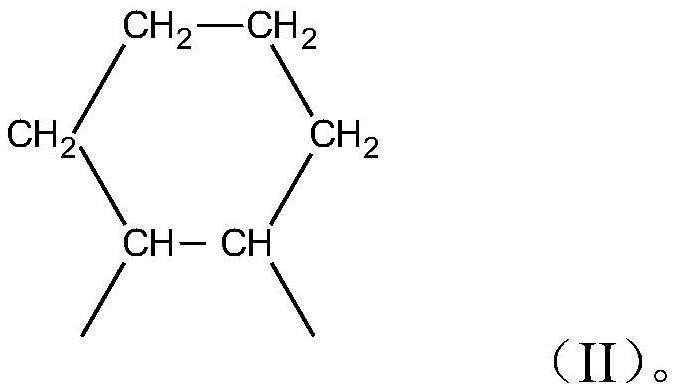

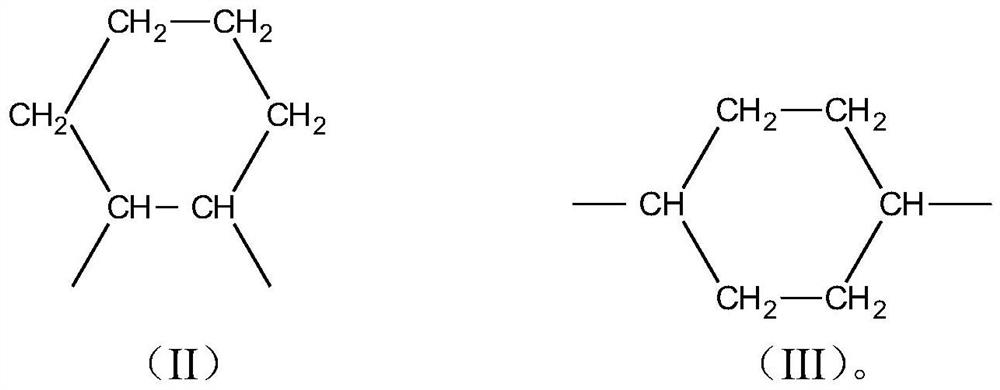

[0024] According to a first embodiment of the invention, the highly saturated elastomer comprises UD units of formula (II) and may optionally comprise UE units of formula (III):

[0025]

[0026] Preferably, the highly saturated elastomer comprises the following UA, UB, UC, UD and UE units randomly distributed according to the mole percentages shown below:

[0027] UA) mole percent is m% -CH 2 -CH 2 -

[0028] UB) mole percent is n%-CH 2 -CH=CH-CH 2 -

[0029] UC) mole percent is o% -CH 2 -CH(CH=CH 2 )-

[0030]

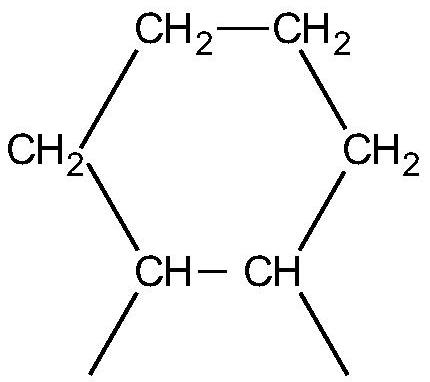

[0031] UD) Mole percentage is p%

[0032] UE) mole percentage is q%

[0033] m, n, o, p and q are numbers from 0 to 100,

[0034] m>50

[0035] n+o>0

[0036] p>0

[0037] q≥0,

[0038] • The respective mole percentages of m, n, o, p and q are calculated based on the sum of m+n+o+p+q equal to 100.

[0039] More preferably:

[0040] 0

[0041] o+p+q≥5

[0042] n+o>0

[0043] q≥0,

[0044] • The respective mole percentages of m, n, o,...

Embodiment approach

[0077] According to a preferred embodiment of the invention, the rubber composition according to the invention is prepared by a process comprising the following stages:

[0078] a. adding to the elastomer matrix reinforcing fillers and optionally other components of the rubber composition other than dithiosulfate, sulfur and vulcanization accelerators constituting the vulcanization system,

[0079] b. Thermomechanical kneading of the mixture obtained in stage a) until reaching a maximum temperature between 110° C. and 190° C.,

[0080] c. cooling the combined mixture to a temperature of less than 100°C,

[0081] d. Subsequent addition of dithiosulfate, sulfur and vulcanization accelerator,

[0082] e. Kneading all substances to a maximum temperature of less than 110° C. to obtain a rubber composition.

[0083] The rubber composition can be in a green state (before vulcanization) or a cured state (after vulcanization).

[0084] The above and other features of the invention w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com