Paint spraying machine suitable for wood industry

A paint spraying machine and wood industry technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of wood being damp and moldy, being eaten by insects, and taking a long time, so as to achieve the effect of high efficiency and precision of the machine, improvement of work efficiency, and improvement of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

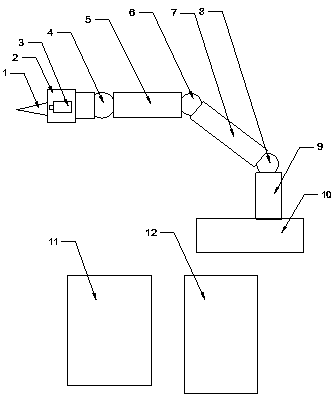

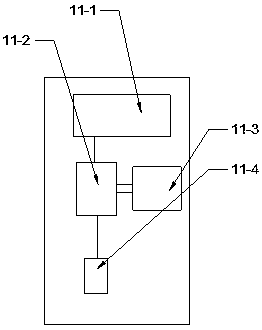

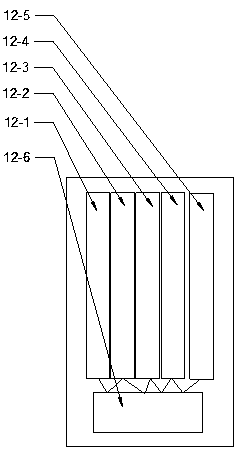

[0018] Such as Figure 1 to Figure 5 As shown, the paint spraying machine suitable for wood industry includes nozzle 1, nozzle 2, camera 3, front-end steering joint 4, front-end support arm 5, middle-section steering joint 6, middle-section support arm 7, lower-end steering joint 8, The lower support arm 9, the paint sprayer base 10, the paint supply box 11 of the paint sprayer and the paint mixing box 12 of the paint sprayer, the nozzle 1 is fixedly connected to the nozzle 2, and the camera 3 is installed on the surface of the nozzle 2, and the nozzle 2 passes through the front knuckle 4 Connect the front end support arm 5, the front end support arm 5 is connected to the middle section support arm 7 through the middle section change joint 6, the middle section support arm 7 is connected to the lower end support arm 9 through the lower end change direction joint 8, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap