Bottle lid capable of adjusting pouring flow

An adjustable and flow-rate technology, which is applied in the direction of capping with auxiliary devices, sealing parts with unloading devices, closing, etc., can solve the problem of inability to effectively control the flow of the contents in the bottle, the large amount of contents poured out, Waste and other problems, to achieve the effect of convenient size adjustment, improved sealing performance, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

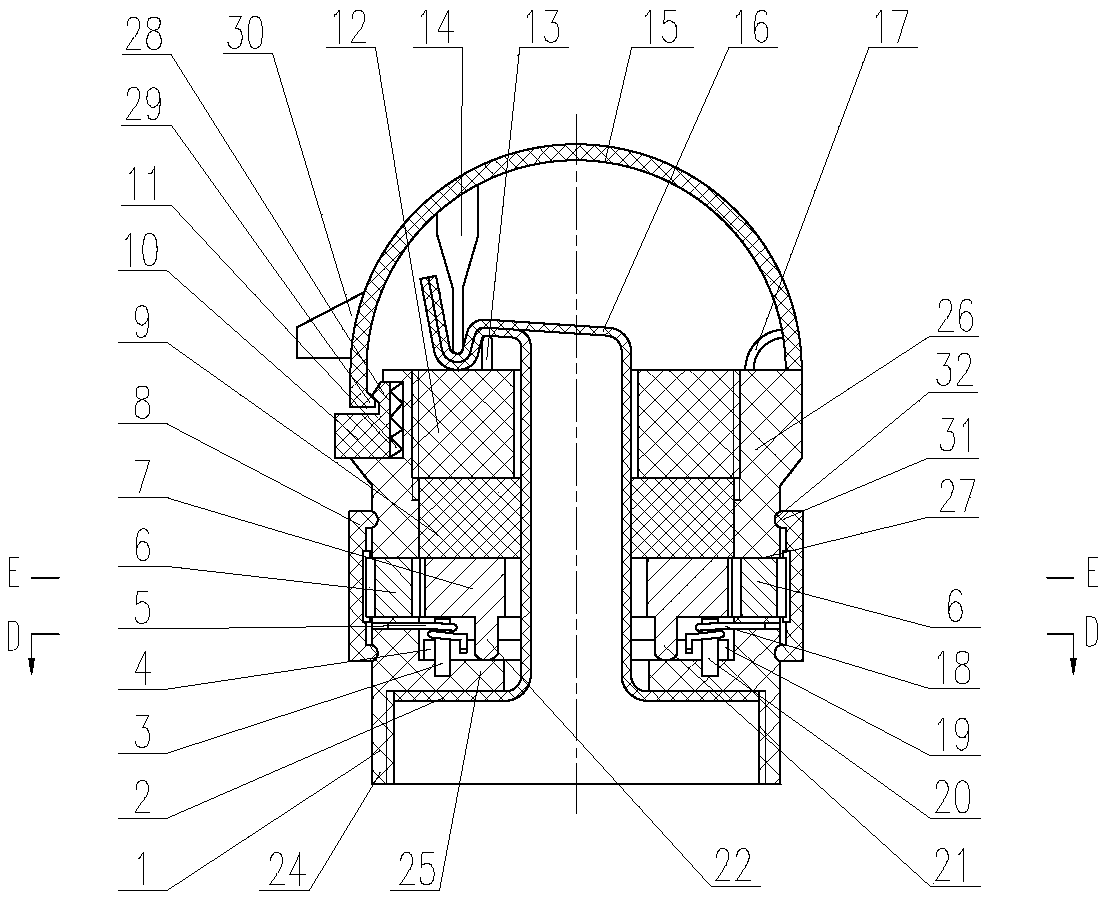

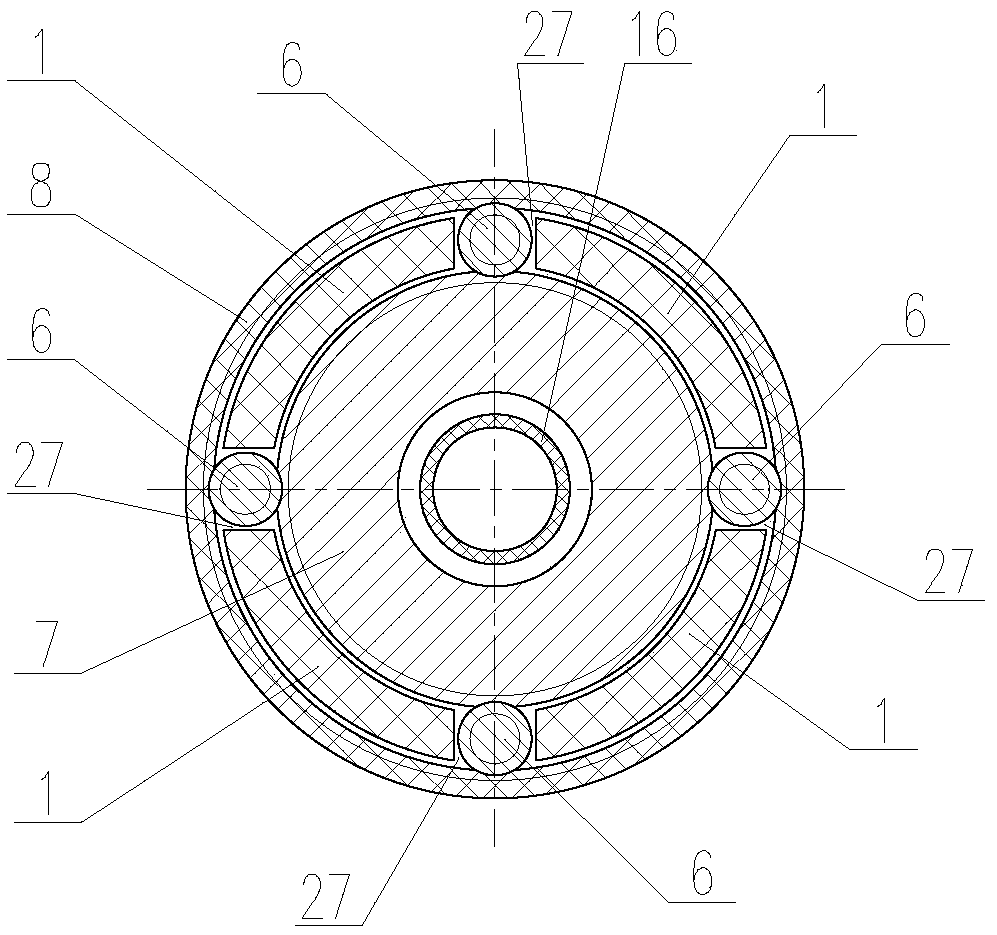

[0042] Such as Figure 1-5 As shown, the present invention records a bottle cap with adjustable pouring flow, including a cap body 1, an inner adjusting ring 7, an outer adjusting ring 8, a gear post 6, a hose 16, a left fixing rod 3, a right fixing rod 20, Left adjustment lever 22, right adjustment lever 21, left adjustment sheet 4, right adjustment sheet 19, left torsion spring 5, right torsion spring 18;

[0043] The cover body 1 is hollow tubular, comprising a lower cover body 24, a middle cover body 25 and an upper cover body 26, the inner diameter of the lower cover body 24 is greater than the inner diameter of the middle cover body 25, and the inner diameter of the middle cover body 25 is smaller than the inner diameter of the upper cover body 26;

[0044] The outer diameter of the hose 16 is not greater than the inner diameter of the middle cover 25, and the axial height of the hose 16 is not less than the sum of the axial heights of the middle cover 25 and the upper cov...

Embodiment 2

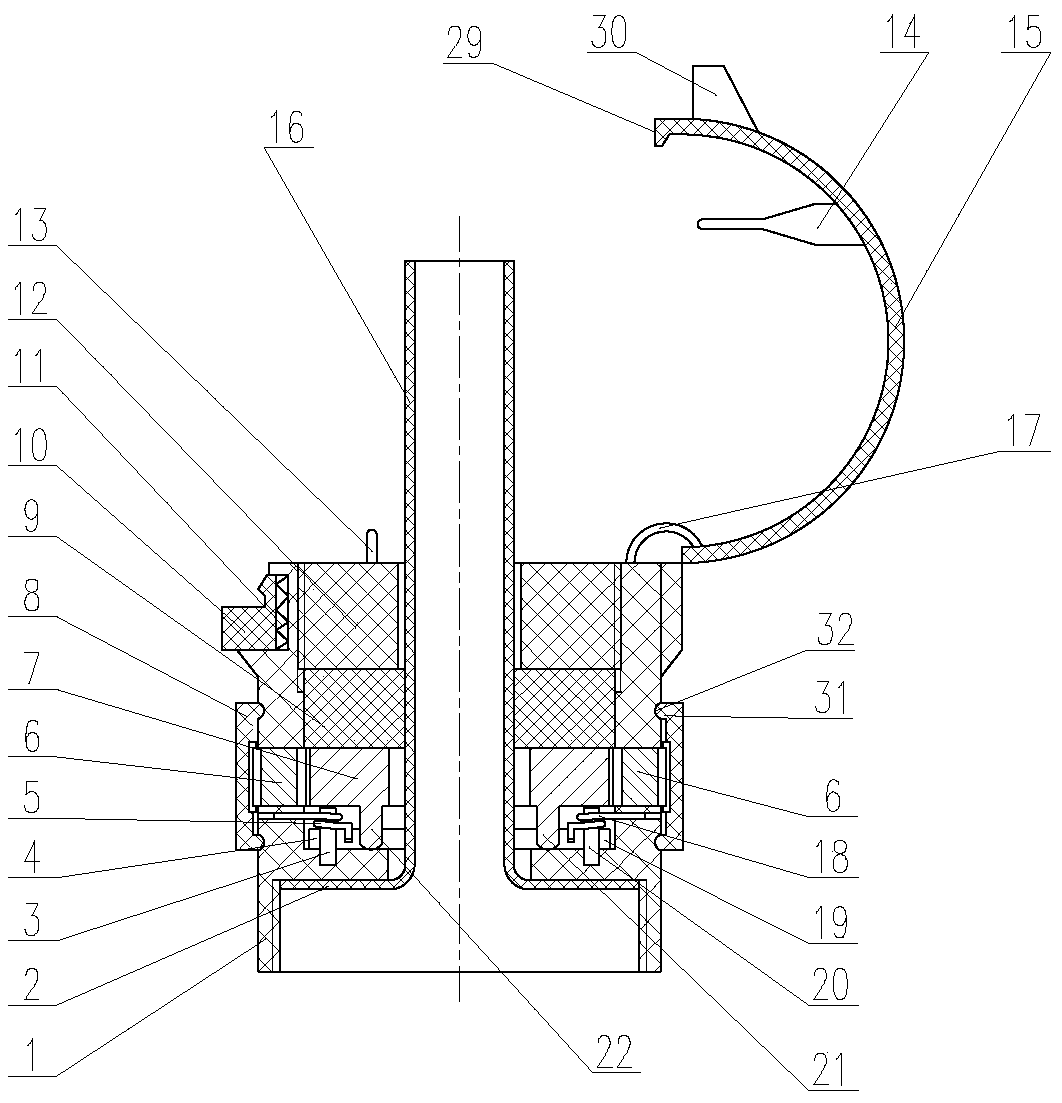

[0052] Such as Figure 6-7 As shown, the present invention records a bottle cap with adjustable pouring flow, including a cap body 1, an inner adjusting ring 7, an outer adjusting ring 8, a gear post 6, a hose 16, a left fixing rod 3, a right fixing rod 20, Left adjusting lever 22, right adjusting lever 21, elastic steel wire 23;

[0053] The cover body 1 is hollow tubular, comprising a lower cover body 24, a middle cover body 25 and an upper cover body 26, the inner diameter of the lower cover body 24 is greater than the inner diameter of the middle cover body 25, and the inner diameter of the middle cover body 25 is smaller than the inner diameter of the upper cover body 26;

[0054] The outer diameter of the hose 16 is not greater than the inner diameter of the middle cover 25, and the axial height of the hose 16 is not less than the sum of the axial heights of the middle cover 25 and the upper cover 26; the lower end of the hose 16 is connected with a lower The sealing sh...

Embodiment 3

[0059] Based on Embodiment 1 and Embodiment 2, the upper cover body of the present invention is provided with spacers, which are located above the inner adjustment ring 7; the inner diameter of the spacer is equal to the outer diameter of the hose 16, and the outer diameter of the spacer is equal to the inner diameter of the upper cover body 26 . A seal is formed between the cushion block and the inner wall of the cover body 1, and a seal is formed between the cushion block and the outer wall of the flexible pipe 16, so as to prevent the contents of the bottle from infiltrating into the interior of the bottle cap from the top of the bottle cap and prevent the contents from remaining inside the bottle cap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com