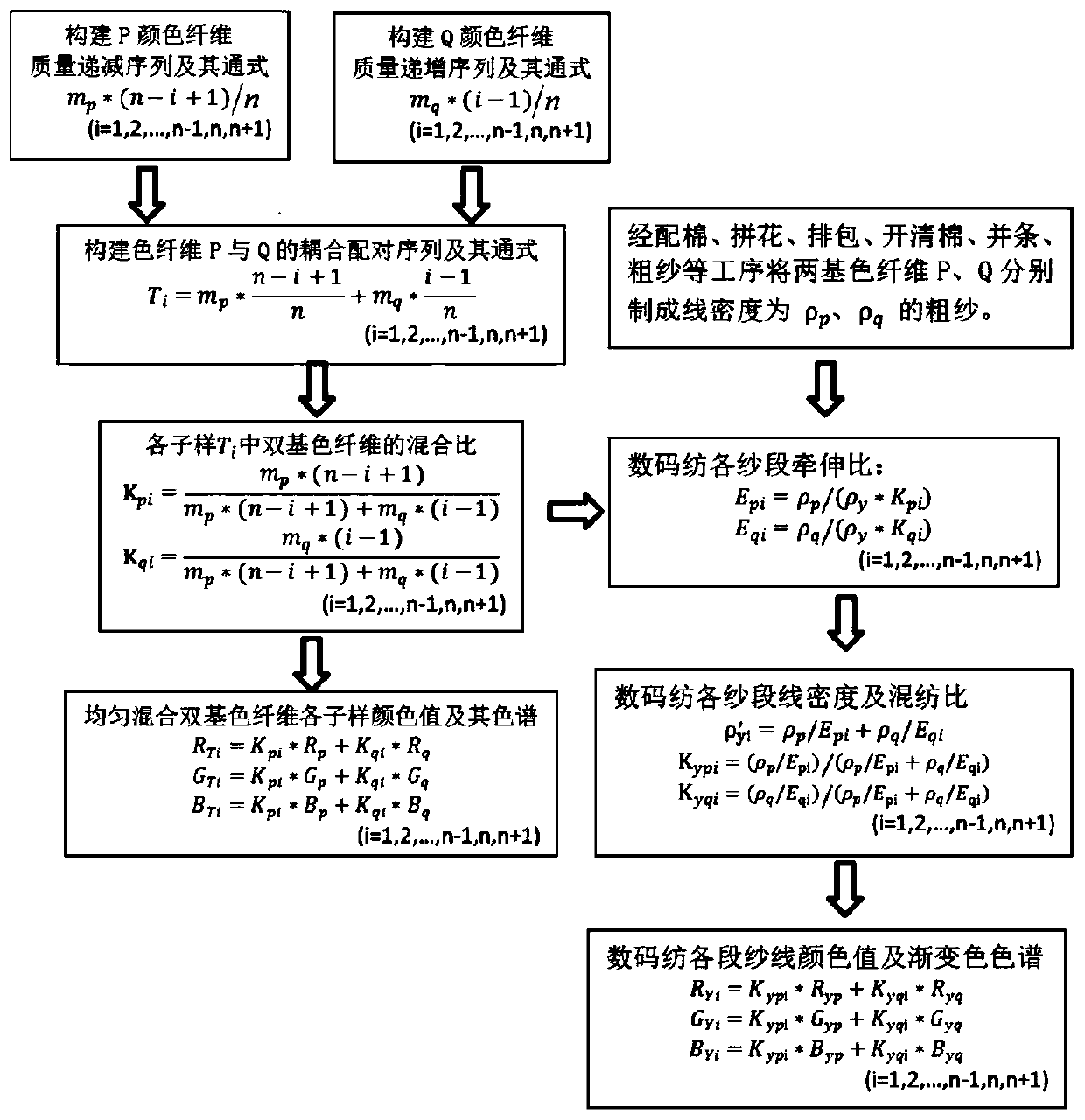

Spinning method for constructing discrete gradient chromatograms and making gradient colored yarns through coupling mixing of double-primary-color fibers

A dual-color, fiber technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of color gradient, inability to mix two-color fibers, and inability to change the mixing ratio of different color fibers online, and achieve secondary color matching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

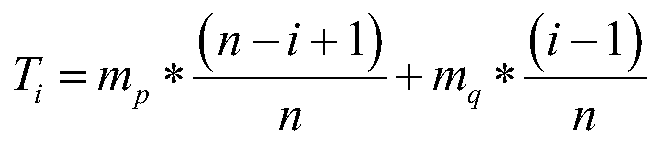

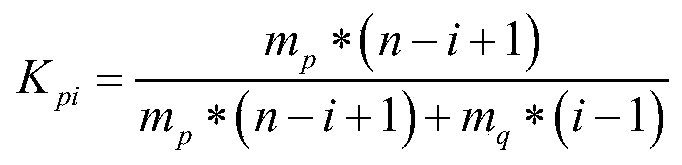

Method used

Image

Examples

Embodiment 2

[0114] Example 2, with the color value and gradient color spectrum of each segment of digital spinning with a gradient of 5%, it is assumed that the linear density of spinning with colored fiber P as raw material is ρ yi The color value of the yarn is (R yp , G yp , B yp ), with the colored fiber Q as the raw material for spinning, the spinning linear density is ρ yi The color value of the yarn is (R yq , G yq , B yq ), then the color value of each segment of the digital spinning digital spinning yarn with a gradient of 5% is calculated by the following formula.

[0115] R Yi = K ypi *R yp +K yqi *R yq

[0116] G Yi = K ypi *G yp +K yqi *G yq

[0117] B Yi = K ypi *B yp +K yqi *B yq

[0118] (i=12...192021)

[0119]

[0120] Table 9

[0121] The discrete gradient chromatogram and the spinning method of the gradient color yarn designed by the coupling and mixing of dual-primary-color fibers designed in the above-mentioned technical scheme use the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com