Method of double-primary color fiber coupling blending and spinning to make gradient yarn based on discrete gradient chromatography

A dual-color and fiber technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of color gradation, inability to change the mixing ratio of different color fibers online, and the inability to mix and match two color fibers, so as to achieve secondary color matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

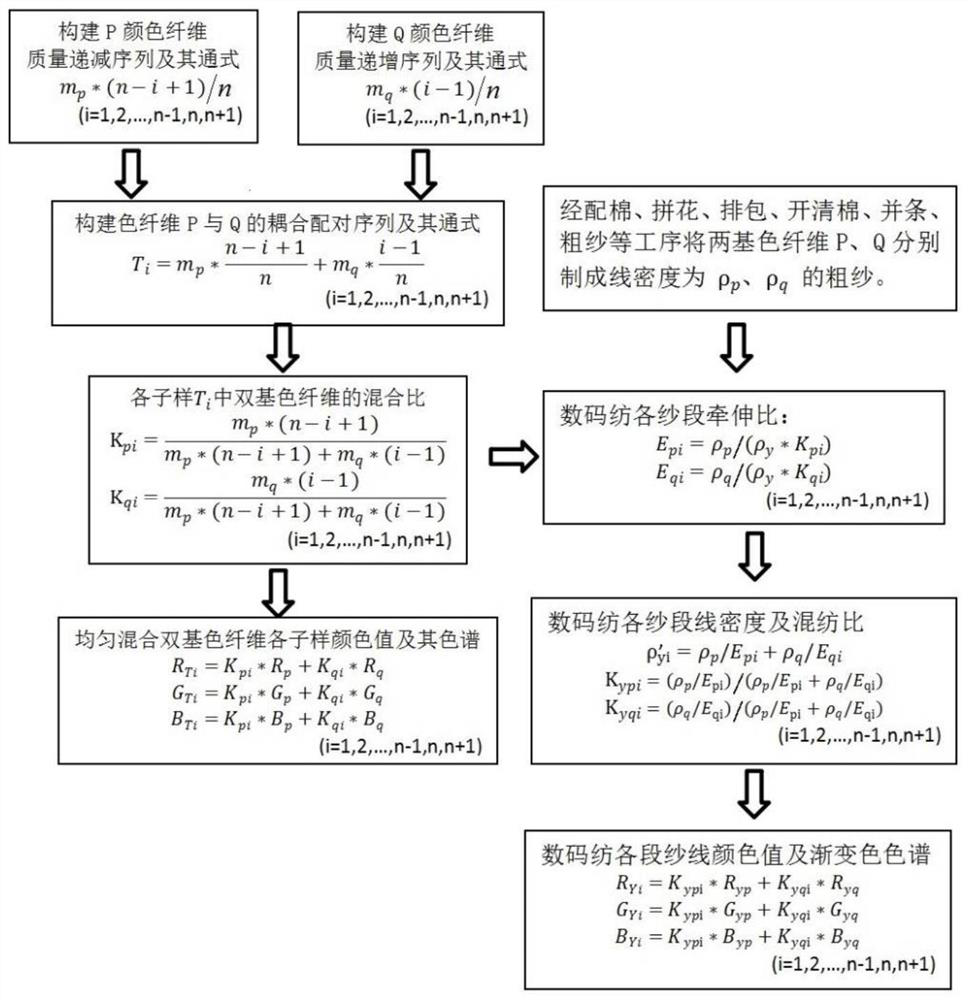

Method used

Image

Examples

Embodiment 2

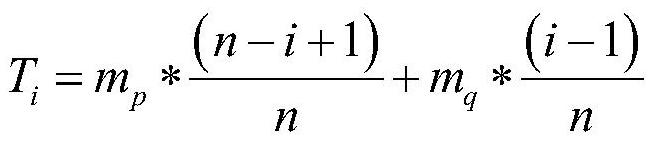

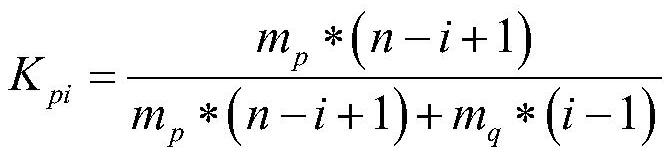

[0116] Example 2, with the color value and gradient color spectrum of each segment of digital spinning with a gradient of 5%, it is assumed that the linear density of spinning with colored fiber P as raw material is ρ yi The color value of the yarn is (R yp , G yp , B yp ), with the colored fiber Q as the raw material for spinning, the spinning linear density is ρ yi The color value of the yarn is (R yq , G yq , B yq ), then the color value of each segment of the digital spinning digital spinning yarn with a gradient of 5% is calculated by the following formula.

[0117] R Yi = K ypi *R yp +K yqi *R yq

[0118] G Yi = K ypi *G yp +K yqi *G yq

[0119] B Yi = K ypi *B yp +K yqi *B yq

[0120] (i=1,2,...,19,20,21)

[0121]

[0122]

[0123] Table 9

[0124] The above-mentioned technical scheme is based on the dual-primary-color fiber coupling blending spinning method for gradient yarn based on the discrete gradient color spectrum. The mass-increasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com