A processing technology of drive linkage in thermoplastic molding equipment

A technology of thermoplastic molding and processing technology, which is applied in the field of processing technology of drive linkages in thermoplastic molding equipment, can solve problems such as difficult drive shaft assembly, and achieve the effect of avoiding poor matching or difficult assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

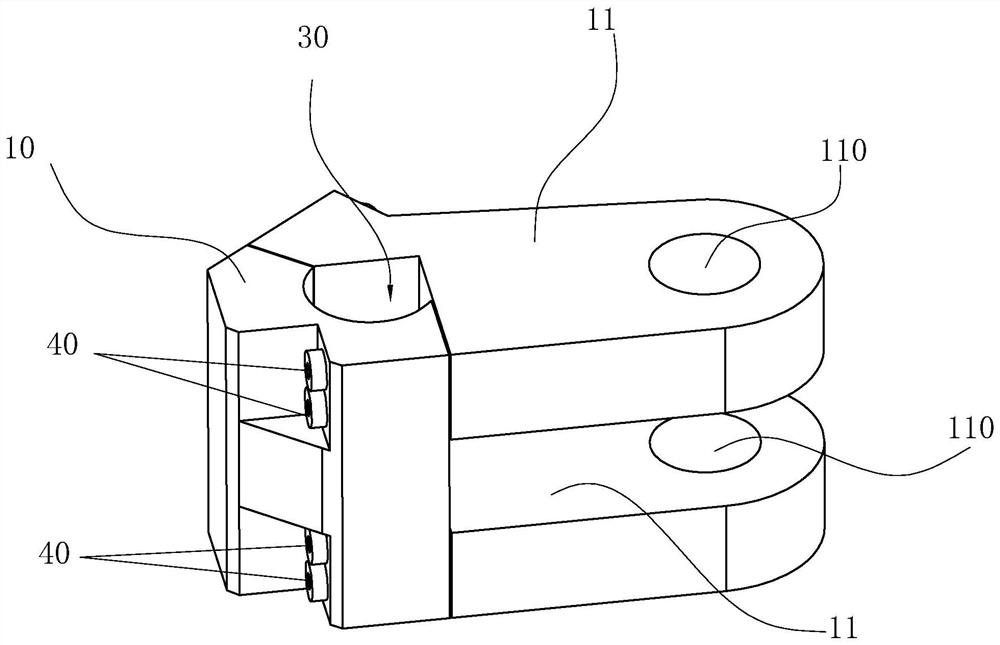

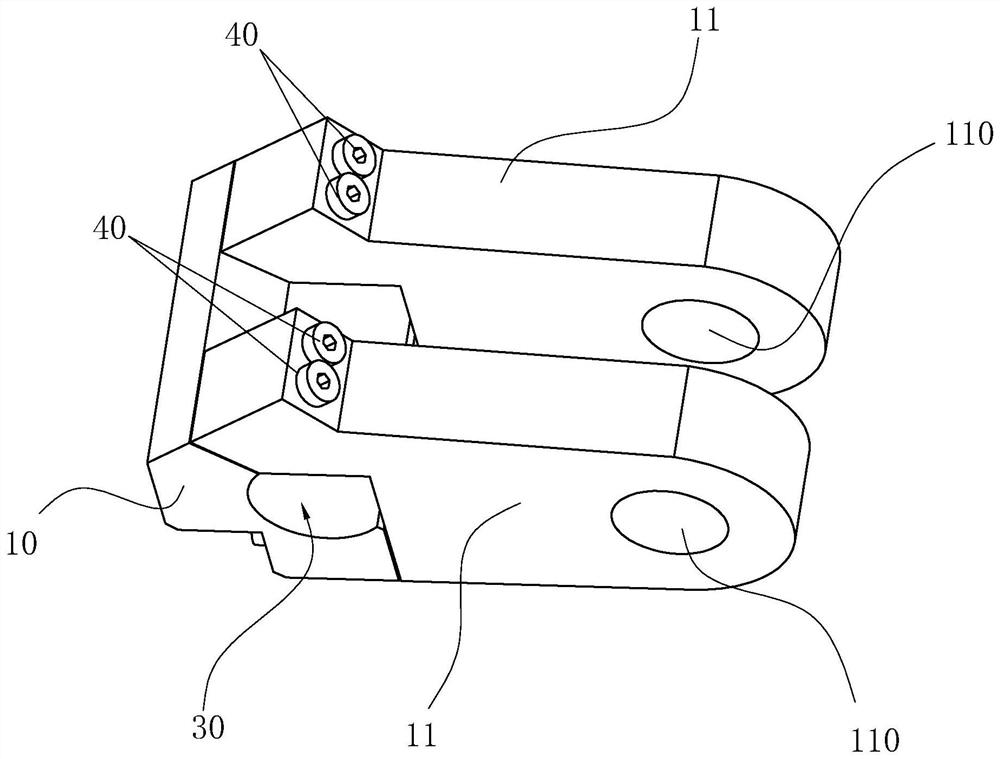

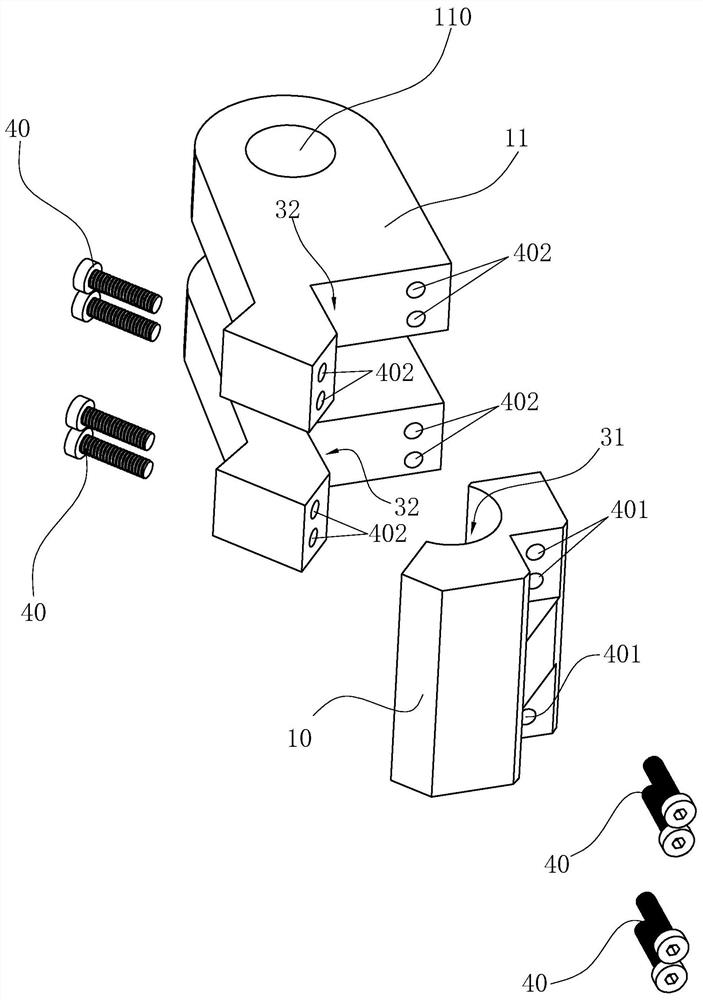

[0026] see Figure 1-Figure 3 The drive link generally includes a link body 10 and a drive arm 11 that can be mated with each other. There are two drive arms 11 of the drive link in this embodiment, and the two drive arms 11 are respectively symmetrically connected to the drive Both sides of the linkage, see Figure 4 and Figure 5 . The mating surfaces of the link body 10 and the driving arm 11 respectively have a half-hole groove, and the two half-hole grooves are fastened to form a special-shaped hole 30 structure, and the special-shaped hole 30 can be sleeved with the drive shaft (not shown) connect. In addition, the two driving arms 11 in this embodiment are also provided with a circular driving hole 110 that can cooperate with another driving shaft, and the centerlines of the two circular driving holes 110 are the same straight line....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com