Automatic biomass particle heating furnace

A technology of biomass pellets and heating furnaces, which is applied in the directions of shaking grate, grate, rotary grate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

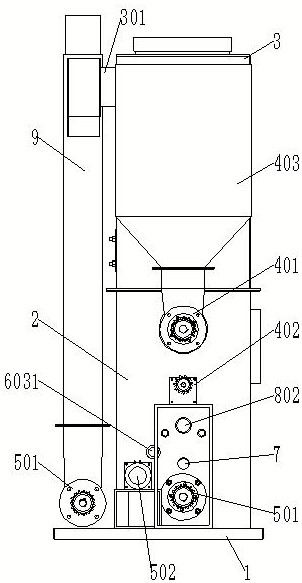

[0026] The main innovation of the present invention is that a combined fire grate consisting of a fixed fire grate 601 and a rotating fire grate 602 is used in the combustion basin 201, and the structure of the grate teeth in the prior art is changed at the same time, avoiding the continuous fire grate. Severe deformation caused by the alternation of cold and heat of the grate teeth during heating operations; meanwhile, the grate teeth 6022 of the rotating grate 602 used in the present invention are simple in structure and easy to manufacture, and are convenient for casting. The working mode of the rotating grate 602 in the present invention is not only applicable to The grate teeth 6022 made of cast iron and the grate teeth 6022 made of ordinary carbon steel will not be seriously deformed and affect the use.

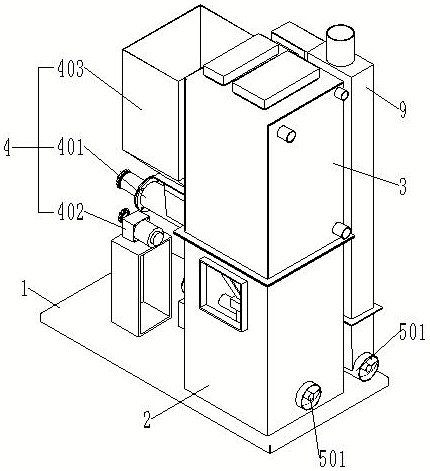

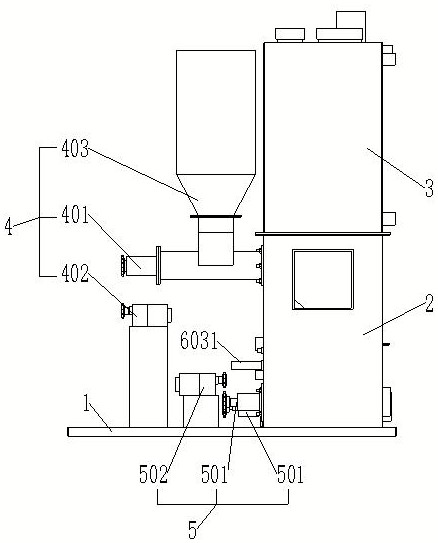

[0027] Such as Figure 1~4 As shown (in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com