Motor

A casing and rotor technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as large pressing force, inability to eliminate concentricity, and reduce service life of end covers, so as to improve service life, facilitate implementation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

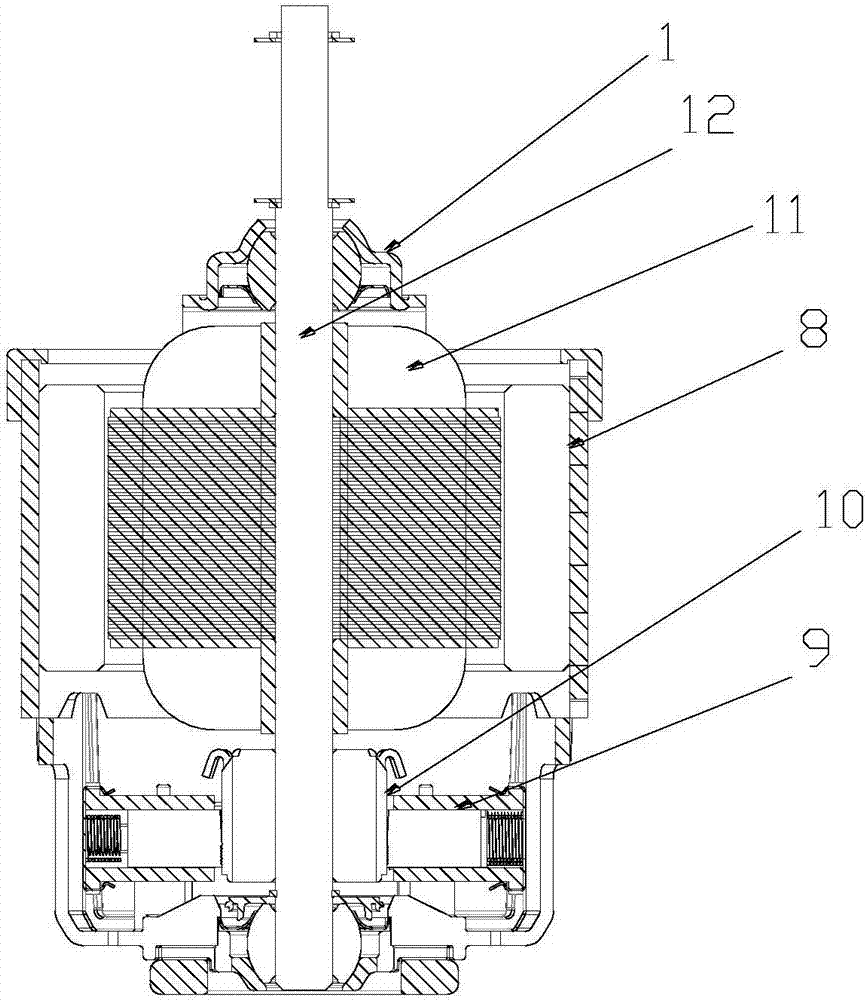

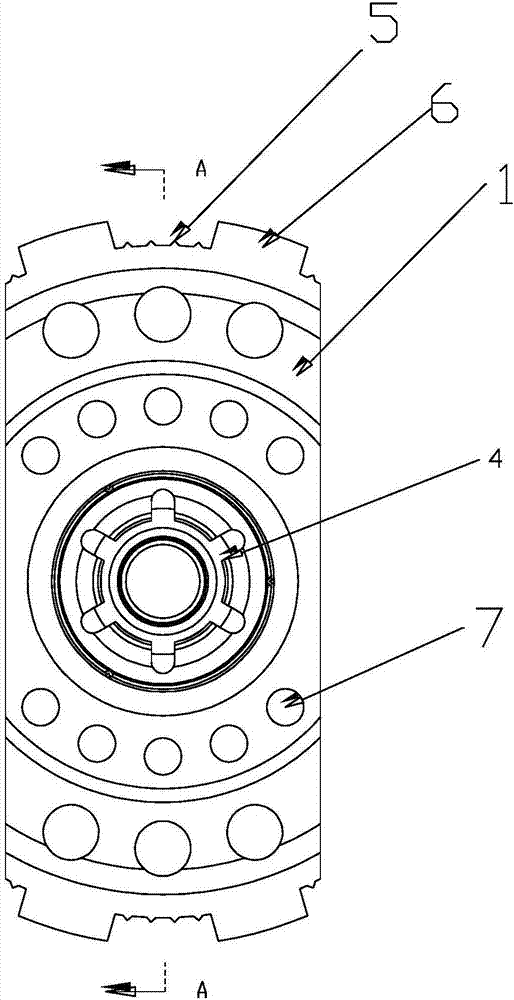

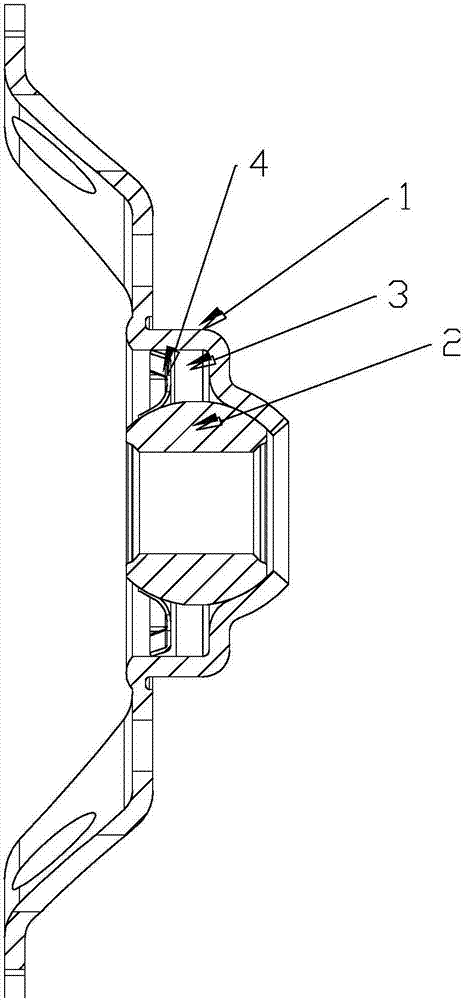

[0018] like Figure 1-3 As shown, a motor includes a housing 8, a carbon brush holder mechanism 9, a commutator 10, a stator and a rotor 11 are arranged in the housing 8, and the rotor 11 includes a The rotating shaft 12, the rotor chip is provided outside the rotating shaft 12, the rotor 11 is provided with coils, and the coils are respectively connected to the carbon brush holder mechanism through the commutator, and the upper and lower ends of the housing 8 are respectively provided with upper and lower ends Cover, the upper and lower end covers include an end cover with a stepped transition structure, a bearing 2 is matched on the inner side of the end face of the end cover, a felt ring 3 is set between the outer surface of the bearing 2 and the end cover, and a felt ring 3 is installed on the inner side of the bearing 2 An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com