Variable-rigidity reinforced pneumatic soft driver

A software driver and enhanced technology, which is applied in the direction of program-controlled manipulators, manufacturing tools, manipulators, etc., can solve problems such as poor stability, poor positioning accuracy of flexible drives, uncontrollable stiffness, etc., and achieve large bending deformation, safety and stability Good, the effect of reducing the size of the drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

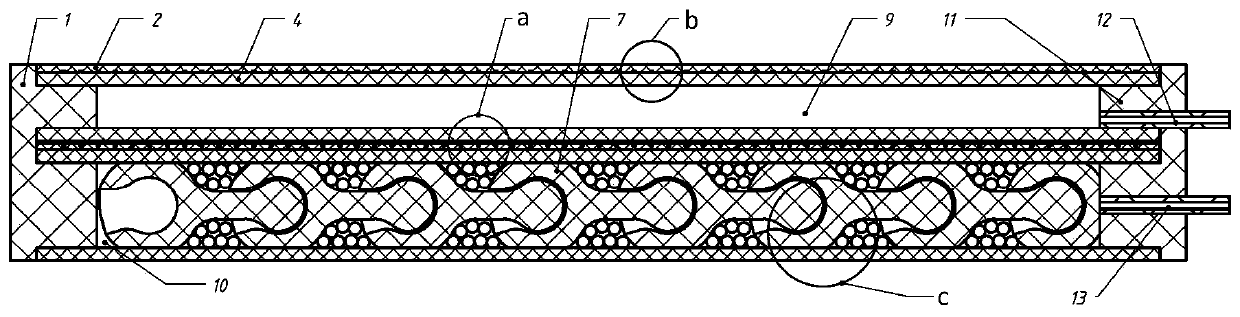

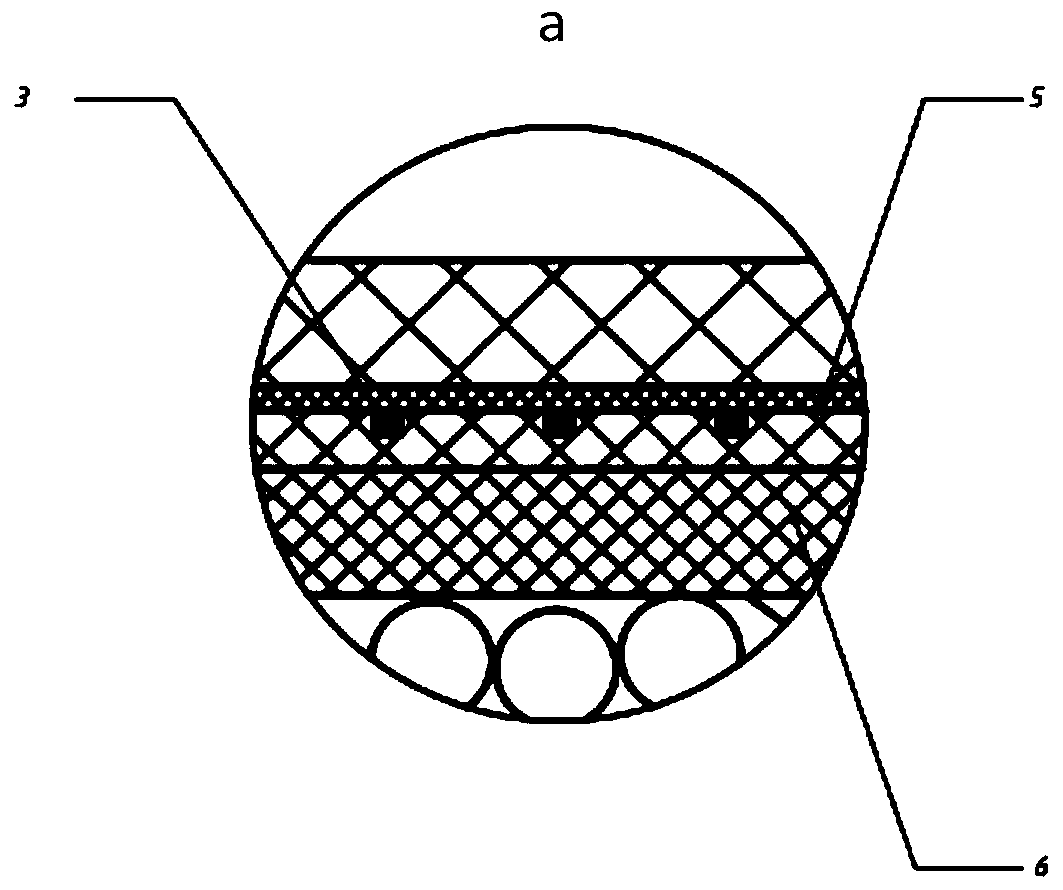

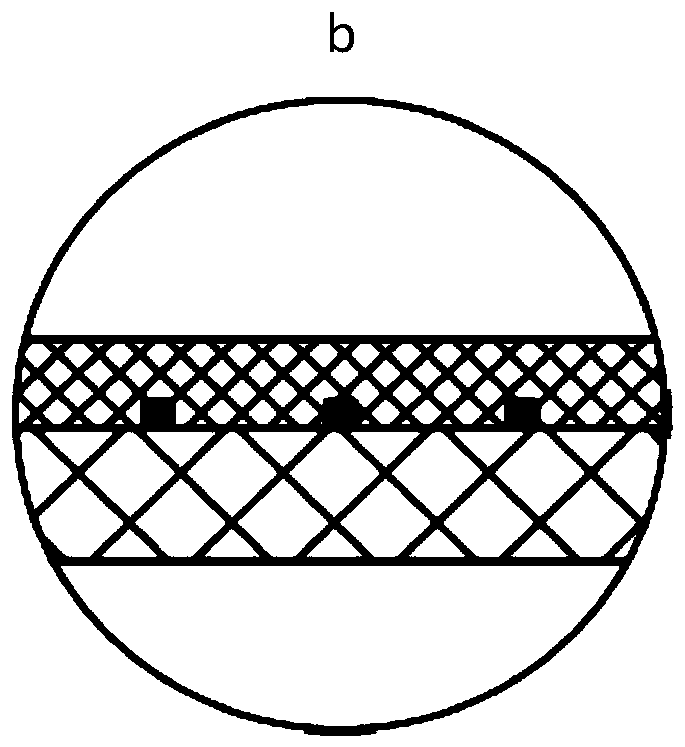

[0029] combine Figure 1 to Figure 13 , the present invention is a variable stiffness enhanced pneumatic software driver, the basic idea of the present invention is to use compressed air to drive and vacuumize for stiffness control.

[0030] combine Figure 1 to Figure 4, a variable stiffness enhanced pneumatic software driver includes a front cover 1, a skin layer 2 outside the driving cavity, a filament 3, an inner core 4 in the driving cavity, an unstrained layer 5, a rigidity adjustment cavity inclusion 6, and a rear end cover 11 , air source inlet duct 12, air source outlet duct 13, some endoskeletons 7 and some particle spheroids 8. The inner core 4 of the drive cavity is a long tube, the inclusion 6 of the stiffness adjustment cavity is a square tube, the non-strained layer 5 is braided, and the unstrained layer 5 is pasted on the bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com