Butterfly valve elastic metal sealing ring and machining technology thereof

A technology of metal sealing ring and elastic metal, which is applied in the direction of lifting valves, valve devices, mechanical equipment, etc., can solve the problems of metal sealing surface scratches, sealing performance degradation, elastic decline, etc., and achieve good reliability of elastic compensation and two-way sealing Good performance and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

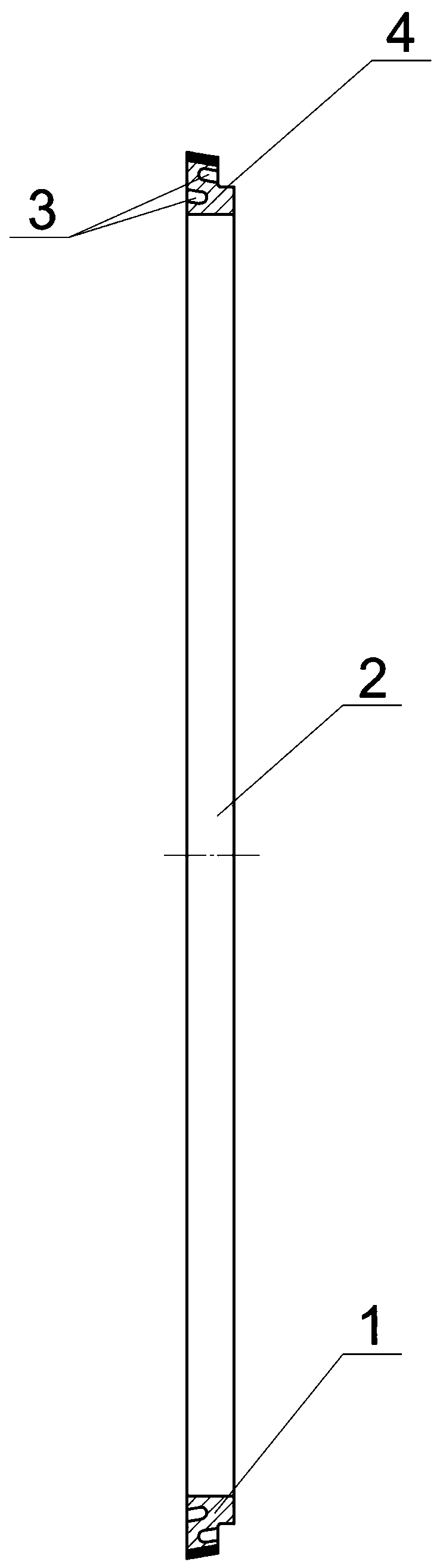

[0023] Such as figure 1 The butterfly valve elastic metal sealing ring and its processing technology shown, its structure includes a metal sealing ring 1, the metal sealing ring 1 has a mounting hole 2 suitable for the butterfly plate; Elastic grooves 3 are formed respectively, and the direction of the elastic grooves 3 on both sides is in the direction of the oblique cone formed by the sealing surface of the metal sealing ring 1, and the center line of the oblique cone formed by the elastic groove 3 is in line with the sealing surface of the metal sealing ring 1. The centerlines of the formed oblique cones coincide; a positioning step 4 is set in the plane of one side of the metal sealing ring 1 .

[0024] The processing technology of butterfly valve elastic metal sealing ring includes the following processes: Process 1: rough machining process, process 2: surfacing process, process 3: finishing process;

[0025] The rough machining process includes the following processes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com