3D printing lathe

A 3D printing and lathe technology, applied in the field of 3D printing lathes, can solve problems such as safety hazards, and achieve the effect of ensuring safety and protecting students

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

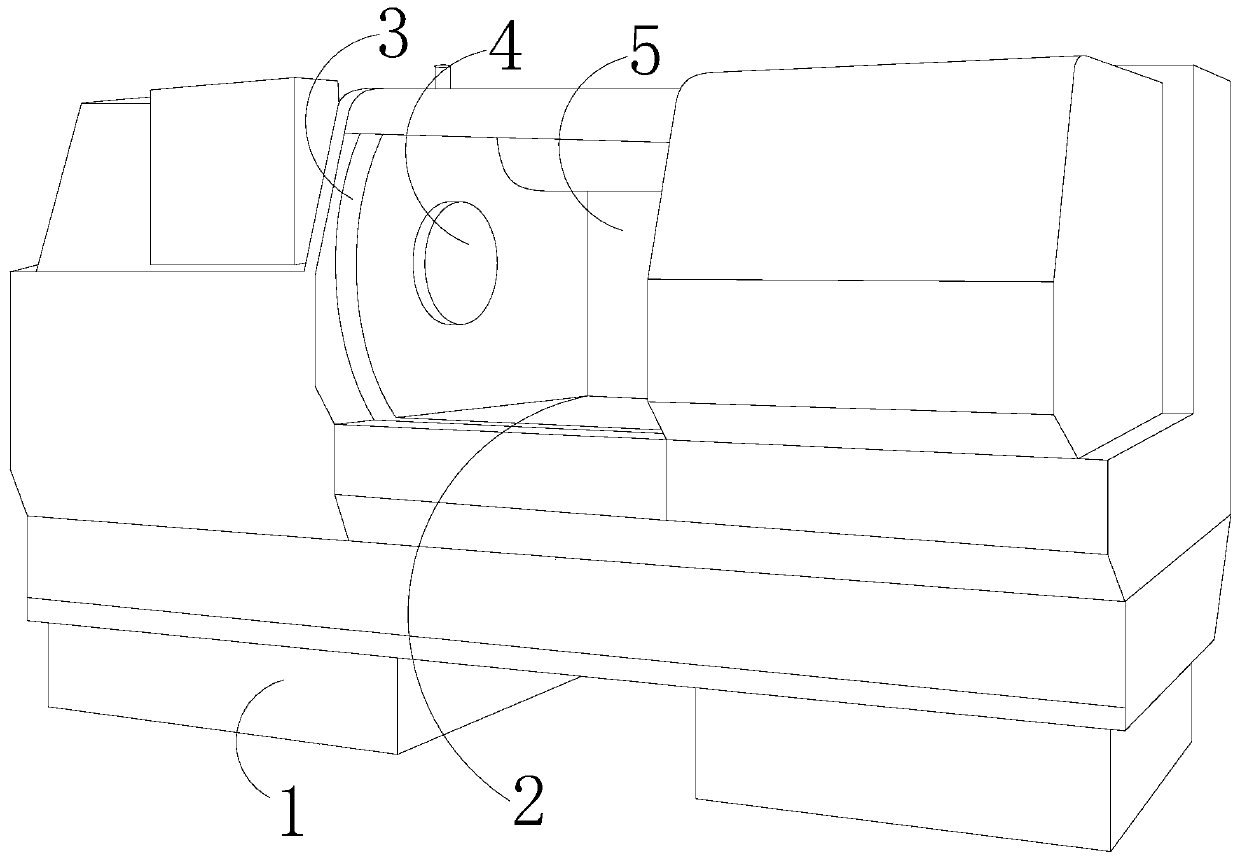

[0028] see Figure 1-Figure 9 , the present invention provides a 3D printing lathe, the structure of which includes a main body 1, a processing table 2, an isolation device 3, a working spindle 4, and a processing chamber 5. The main body 1 is provided with a processing table 2, and the processing table 2 is installed on In the center of the bottom of the processing chamber 5, the processing chamber 5 is located at the center of the main body 1, the processing chamber 5 is set on the main body 1 in the form of an inward depression, and the working spindle 4 is arranged on the inner side panel of the processing chamber 5. The isolating device 3 is matched with the processing chamber 5, and the isolating device 3 is connected with the processing table 2;

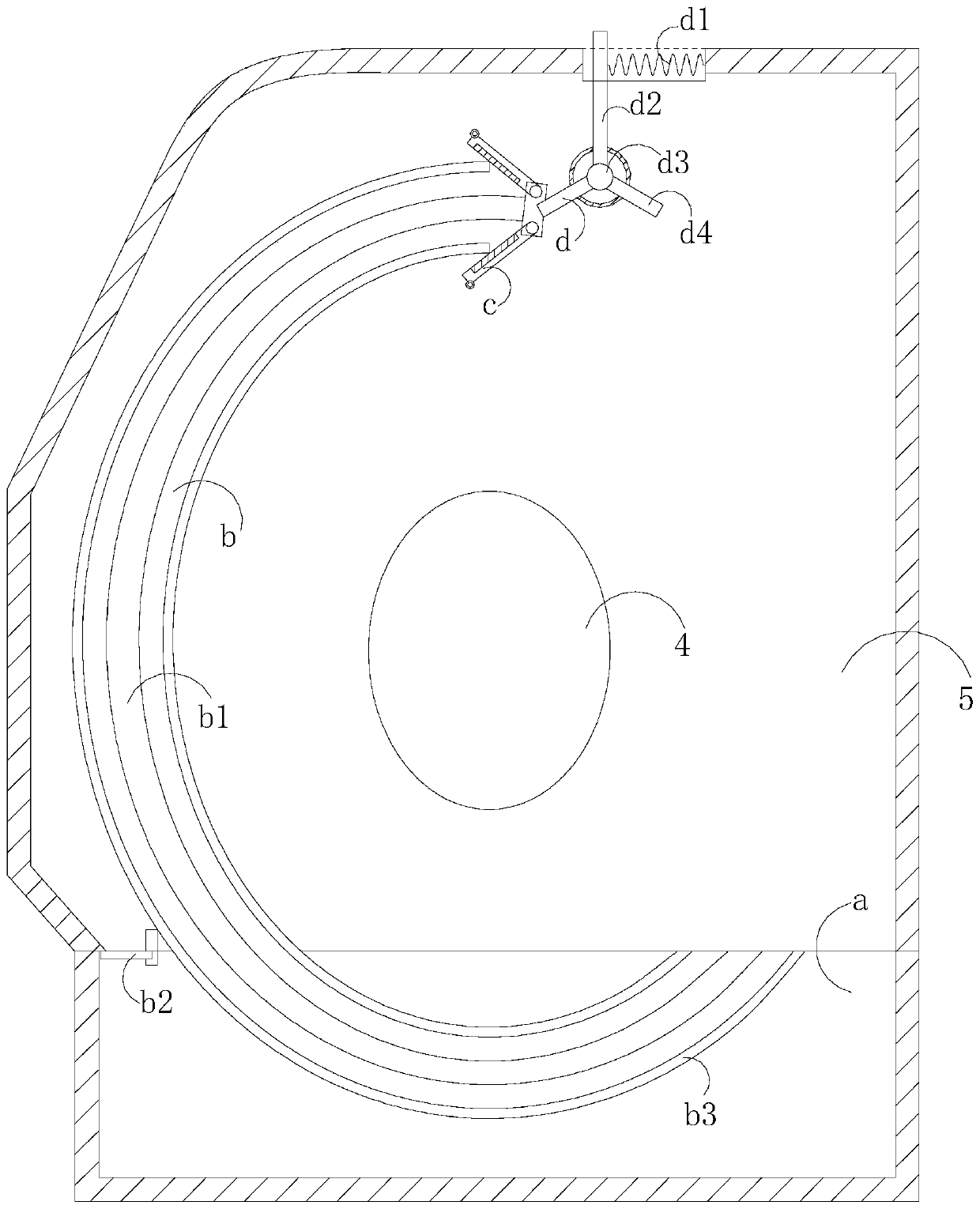

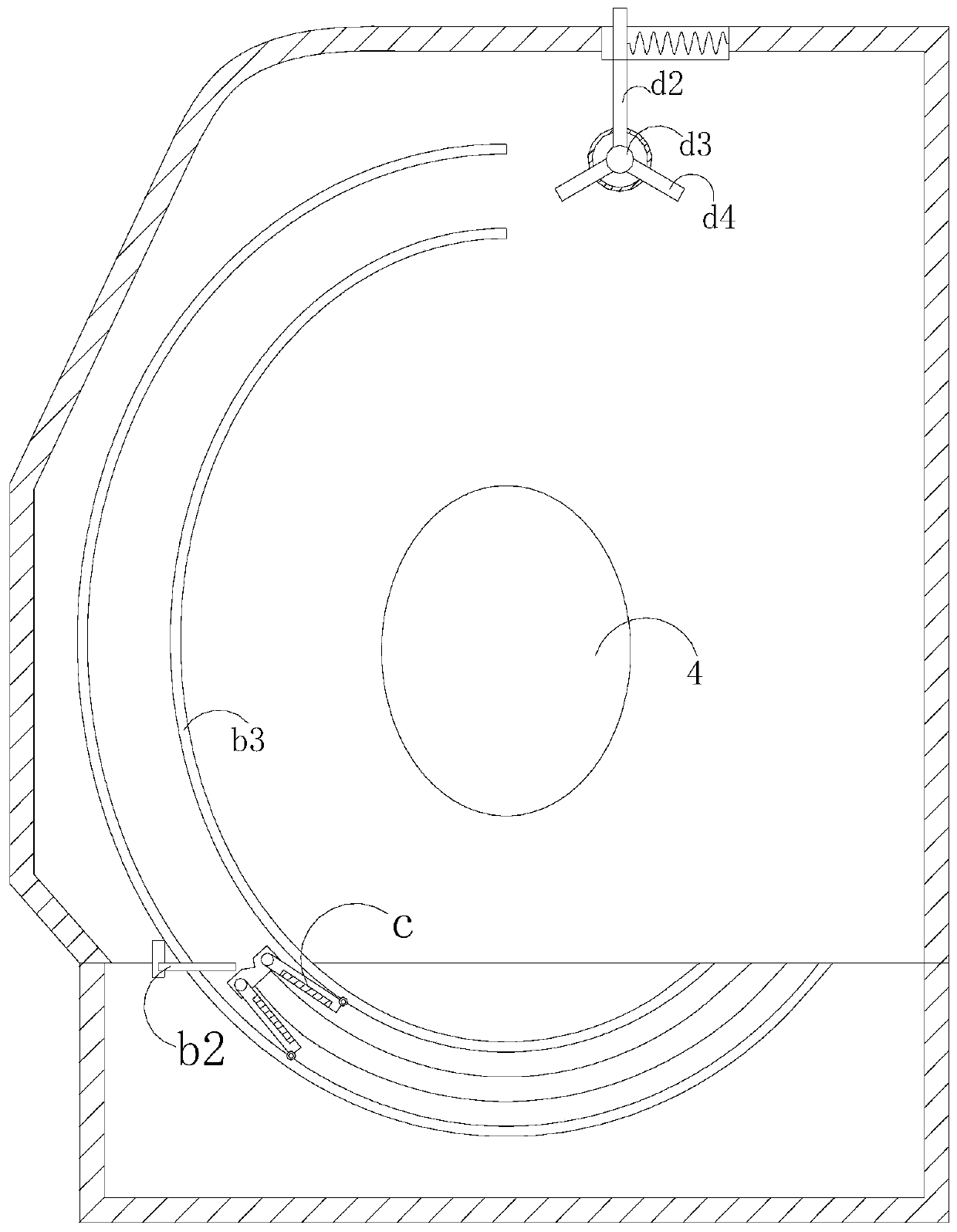

[0029] The isolation device 3 is composed of a No. 1 chamber a, an isolation protection mechanism b, an engaging block c, and a drive rod d. The isolation protection mechanism b is connected to the No. 1 chamber a, and the iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com