Demisting device utilizing tap water

A defogging device and tap water technology, applied in the direction of dispersed particle separation, steam condensation, chemical instruments and methods, etc., can solve the problems of indoor humidity, high energy consumption, slow defogging speed, etc., and achieve the effect of reducing indoor humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

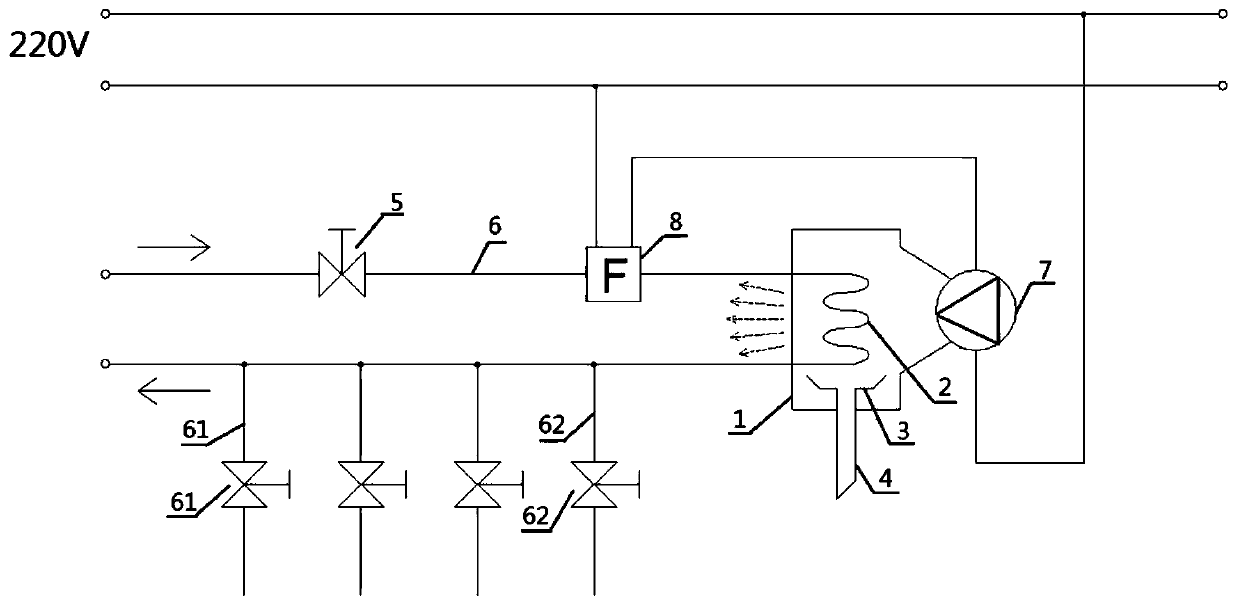

[0015] like figure 1 Shown, a kind of defogging device utilizing tap water, hereinafter referred to as defogging device, external tap water flows into the main pipe 6 of the tap water pipe network in the family through the main water pipe valve 5, and a plurality of water distribution pipes 61 are connected in parallel on the main pipe. All are provided with water diversion valve 62 on each water diversion pipe.

[0016] The demisting device mainly includes a casing 1 , a coil pipe 2 , a water receiving tray 3 , and a drain pipe 4 . The coil is installed in the casing, the water tray is installed under the condenser, the drain pipe is installed on the bottom wall of the water tray and extends downward through the casing, and the casing is installed in the room or in the reserved opening on the wall ; There are multiple air holes on the casing; the coil in the casing is connected in series with the main pipe 6, so that part or all of the water pipes are located downstream of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com