Magnetic type self-switching infrared monitor

A self-switching and monitoring technology, applied in CCTV systems and other directions, can solve the problems of poor shooting effect, insufficient light, fixed infrared switching time, etc., to achieve the effect of reducing impact, strong flexibility, and improving shooting clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

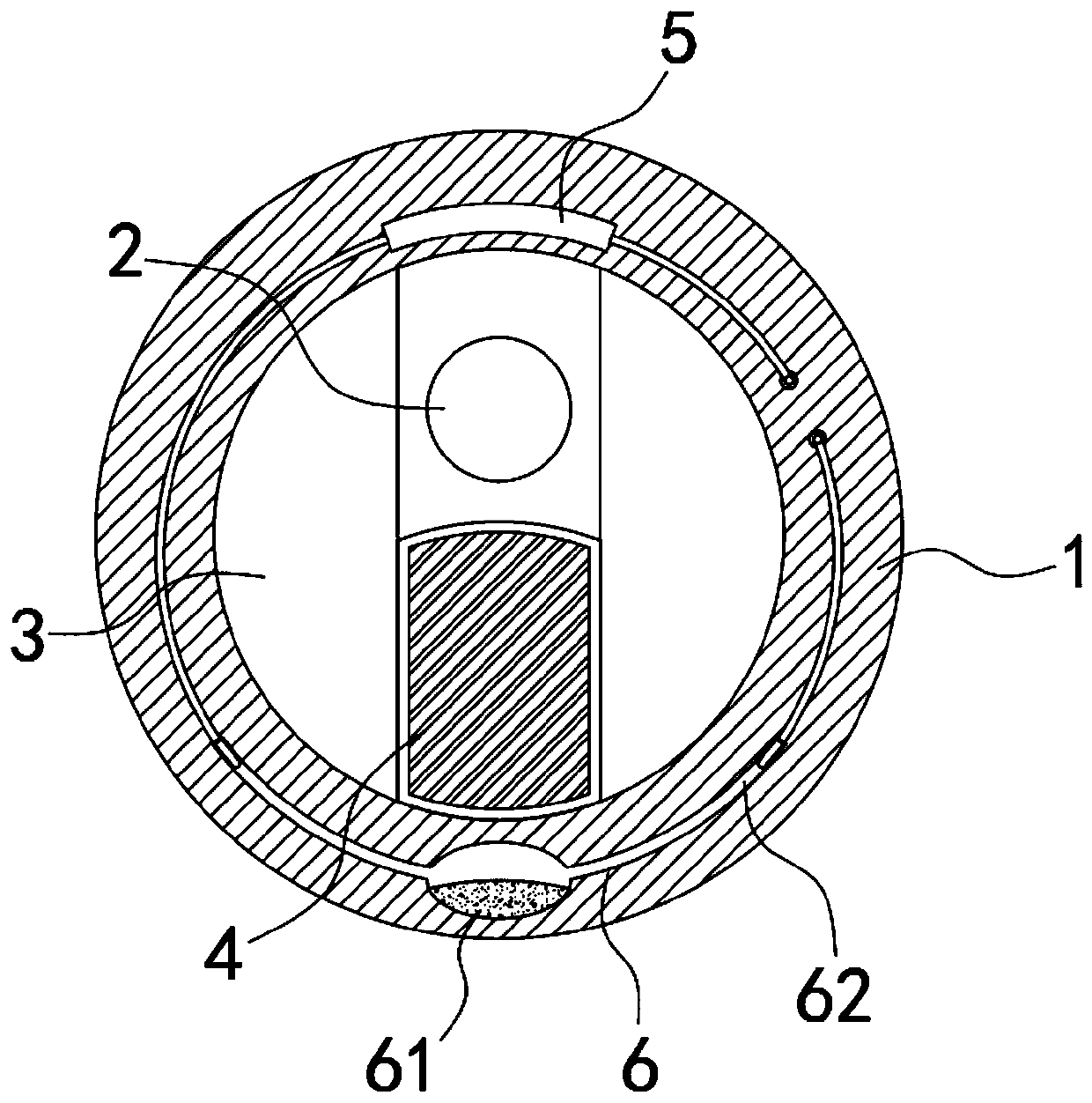

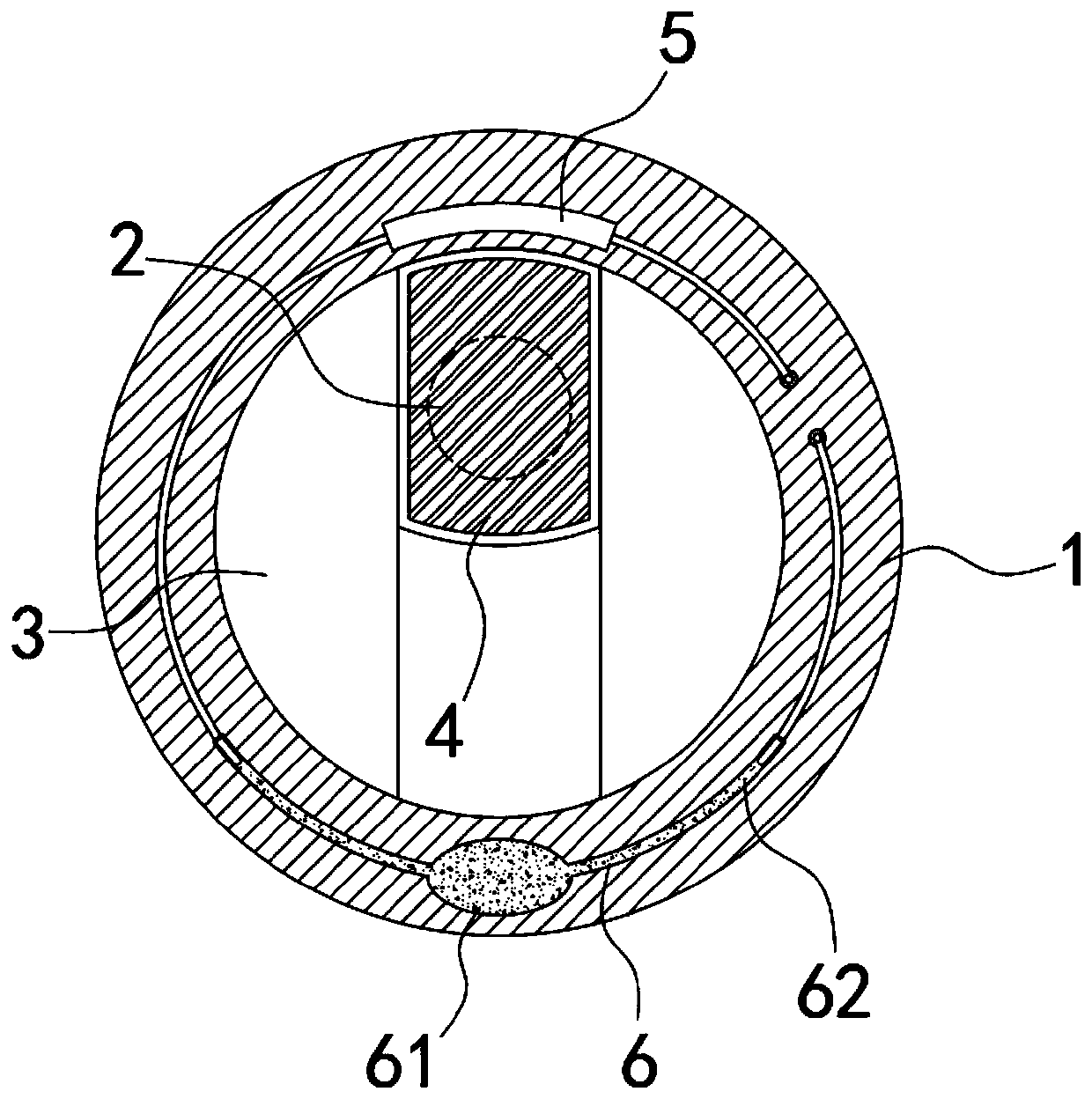

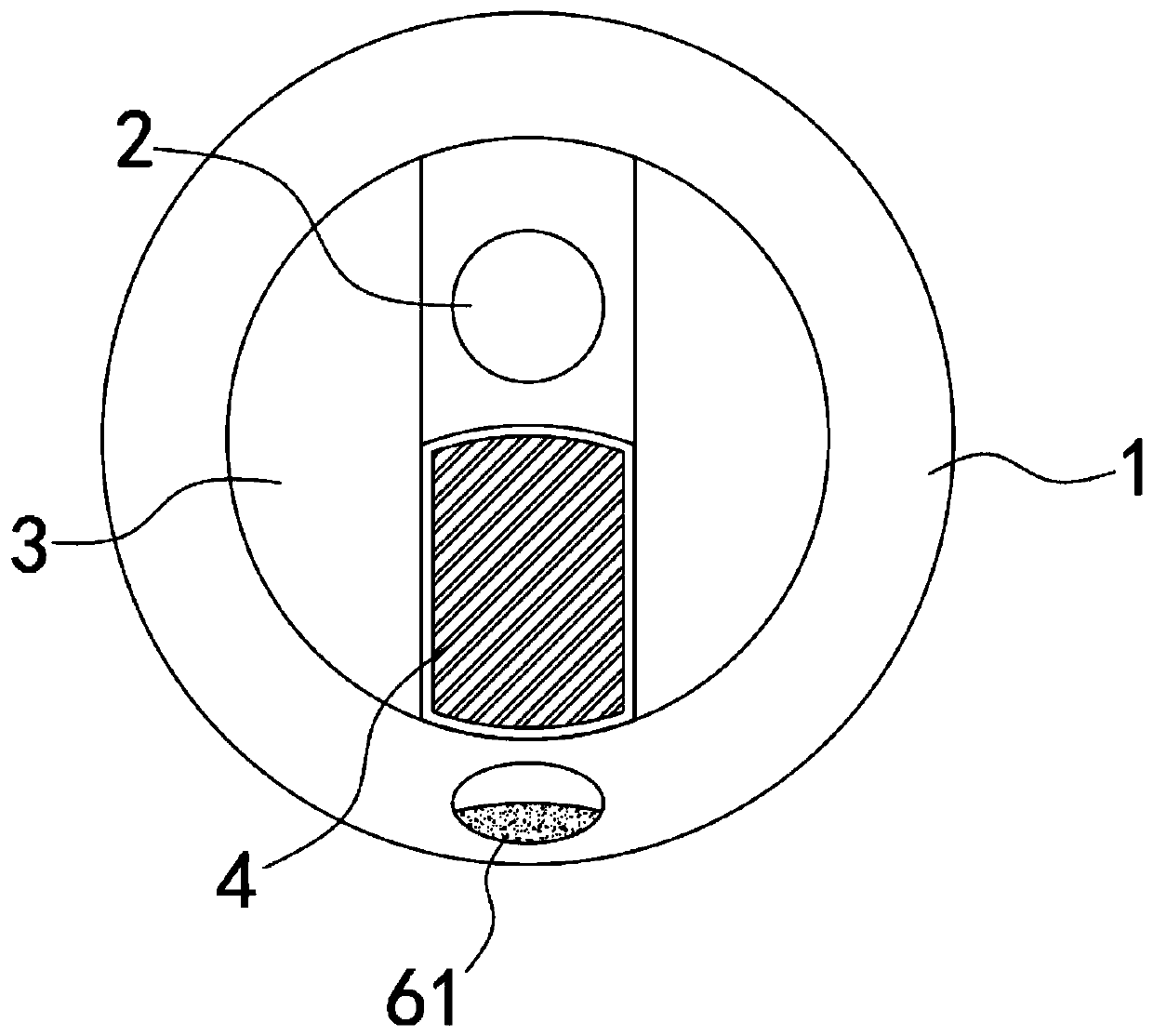

[0020] Such as Figure 1-3 As shown, a magnetic self-switching infrared monitor includes a cylindrical housing 1, and a monitoring head 2 is installed on the upper half of the housing 1, that is, the monitoring head 2 is arranged on the axis of the cylindrical housing 1 In the above part, both sides of the monitoring head 2 are provided with arc-shaped blocks 3, a vertical slideway is formed between the two arc-shaped blocks 3, and the infrared cut-off plate 4 is slidably connected in the slideway, and the frame of the infrared cut-off plate 4 Using magnetic material, under the initial state, under the action of gravity of the infrared cut-off plate 4, the infrared cut-off plate 4 is at the lowermost side of the slideway (such as figure 1 As shown), at this time, the monitoring head 2 is directly exposed to the outside, which can meet the requirement that the monitoring head 2 has enough light at night or on cloudy days. The upper part of the housing 1 is embedded with an elec...

Embodiment 2

[0024] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the temperature control switch 6 includes a slot arranged on the upper part of the housing 1, and a transparent block 63 is fixedly connected in the slot, and the edge of the transparent block 63 is connected with the housing 1. The outer edge of the transparent block 63 is matched to form a complete cylinder. The cross-section of the transparent block 63 is in the shape of a shuttle that is convex on both sides and pointed at both ends. An upward curved, arc-shaped, A flat vacuum chamber 64 containing mercury, and conductive contacts embedded in the upper end surfaces of both sides of the vacuum chamber 64 .

[0025] In this embodiment, when external strong light passes through the transparent block 63 and irradiates the mercury to increase its temperature, the mercury expands when heated and will cover the vacuum cavity 64 and form a concave mirror. On the one hand, the concave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com