Vehicle tyres having sipe in profile block element

A technology of pneumatic tires and tread blocks, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc., which can solve the problems of reduced stiffness of tread blocks and achieve the effect of improving driving behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

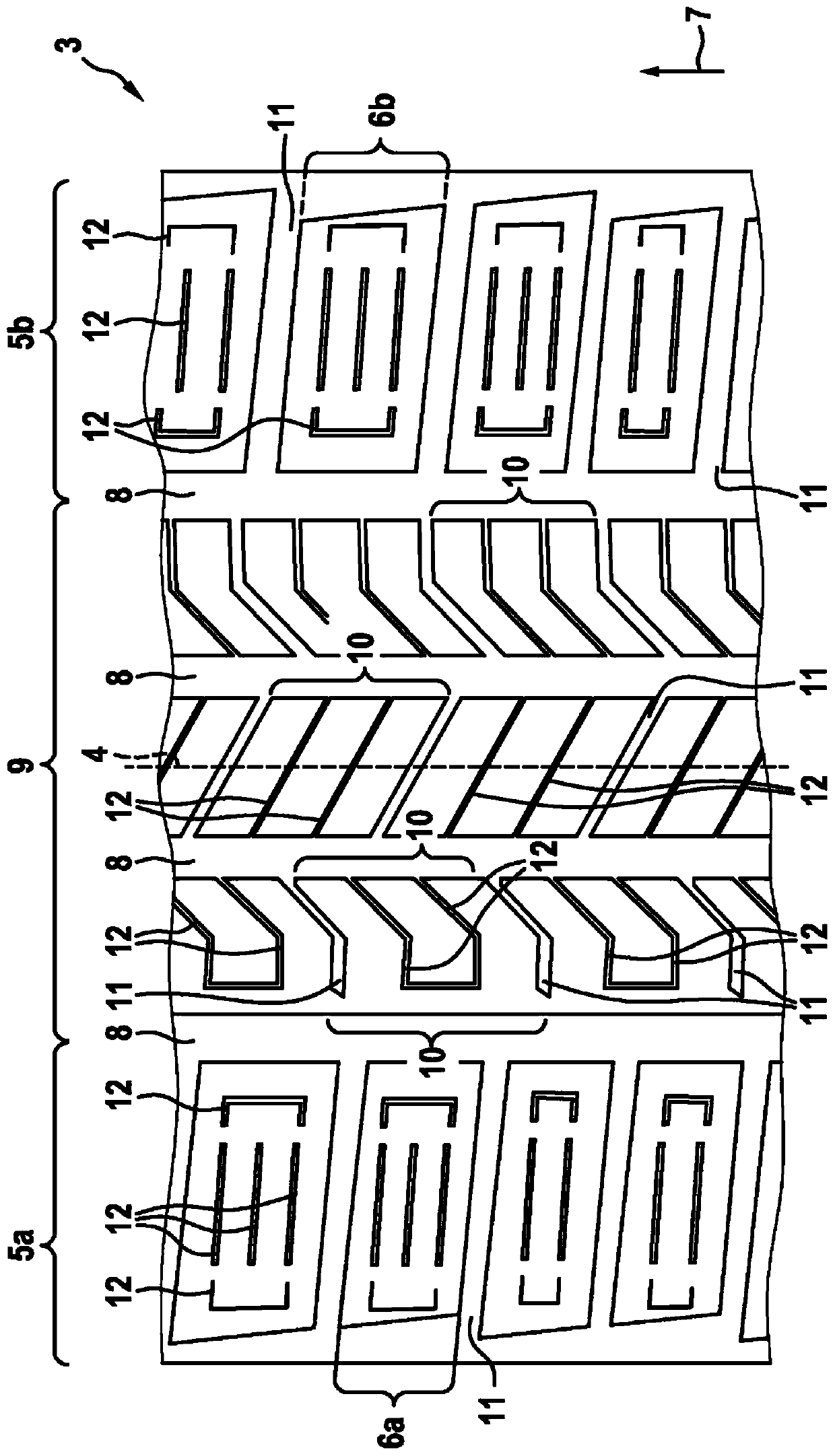

[0095] figure 1 A schematic representation of a tread 3 of a pneumatic tire for vehicles according to the invention according to a first embodiment is shown in plan view, wherein two shoulders 5a, 5b with rows of shoulder block units 6a, 6b are shown And a central tread region 9 with rows of central block units 10 . The tread 3 also has circumferential grooves 8 , transverse grooves 11 and fine incisions 12 . Furthermore, a tire apex 4 is shown in dashed form in the center of the tread 3 . figure 1 The fine cuts 12 in the shoulder block units 6a, 6b are spatially separated from the lateral grooves 11 and the circumferential grooves 8, while the fine cuts 12 in the central block unit 10 lead into Circumferential grooves 8.

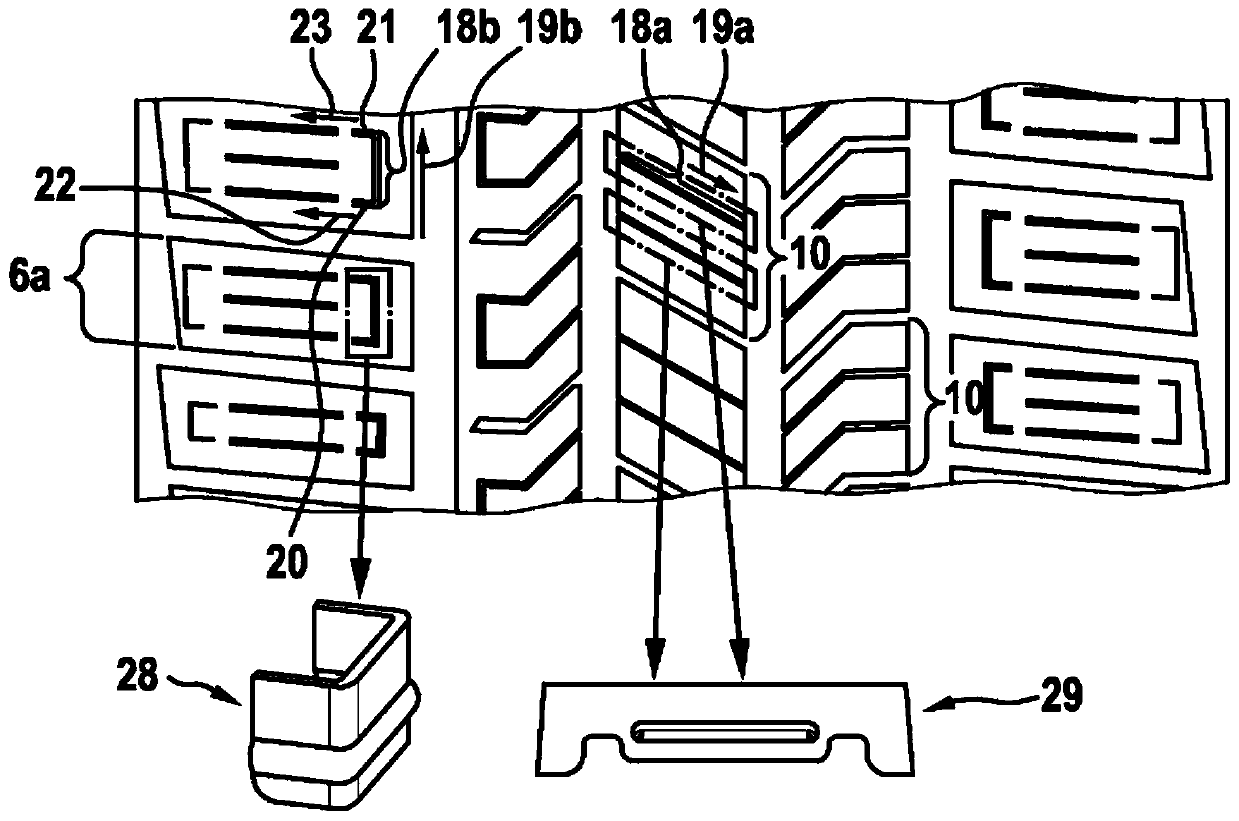

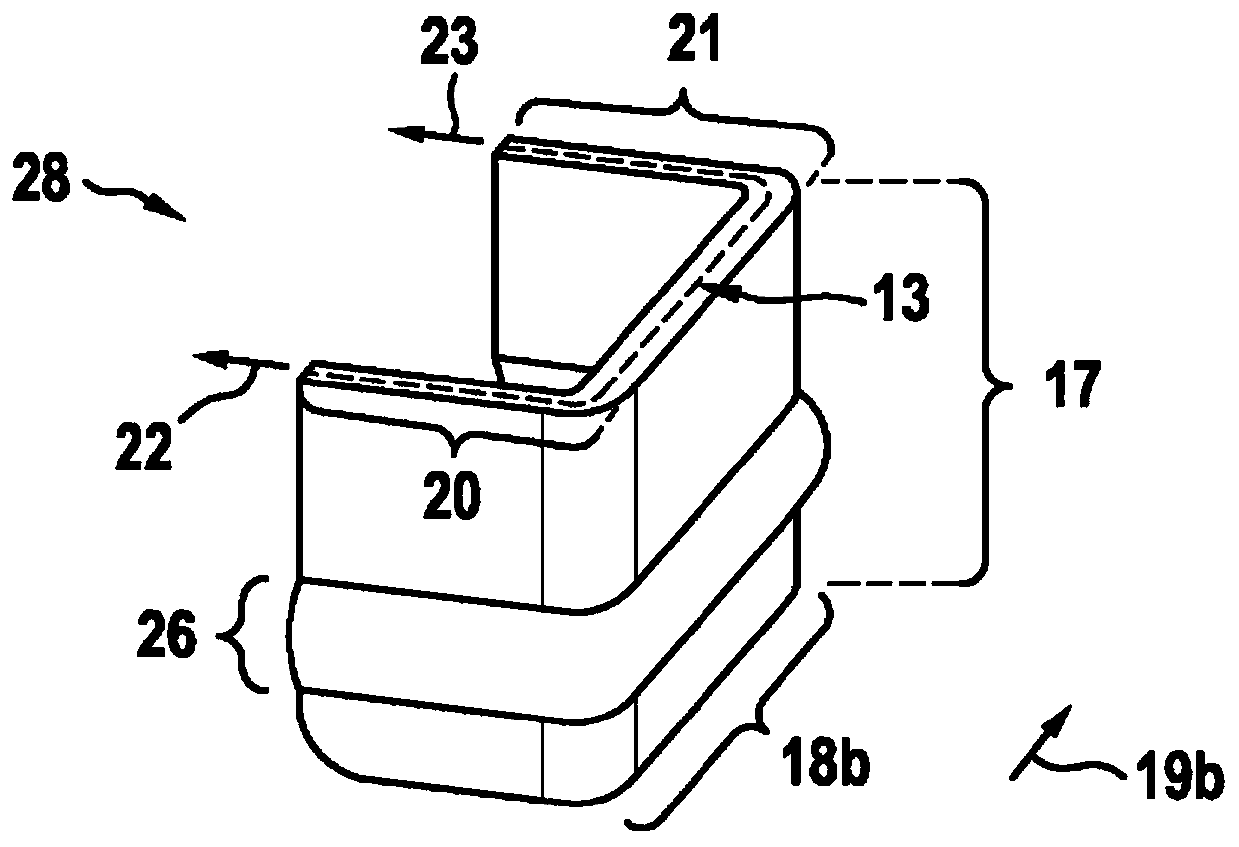

[0096] figure 2 A schematic representation of a tread 3 of a pneumatic tire for vehicles according to the invention in another embodiment is shown in top view, wherein additionally a laminate for the manufacture of fine cuts in a shoulder block unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com