Mobile greenhouse weeding mechanism based on three-coordinate

A three-coordinate, mobile technology, used in harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as inability to weeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

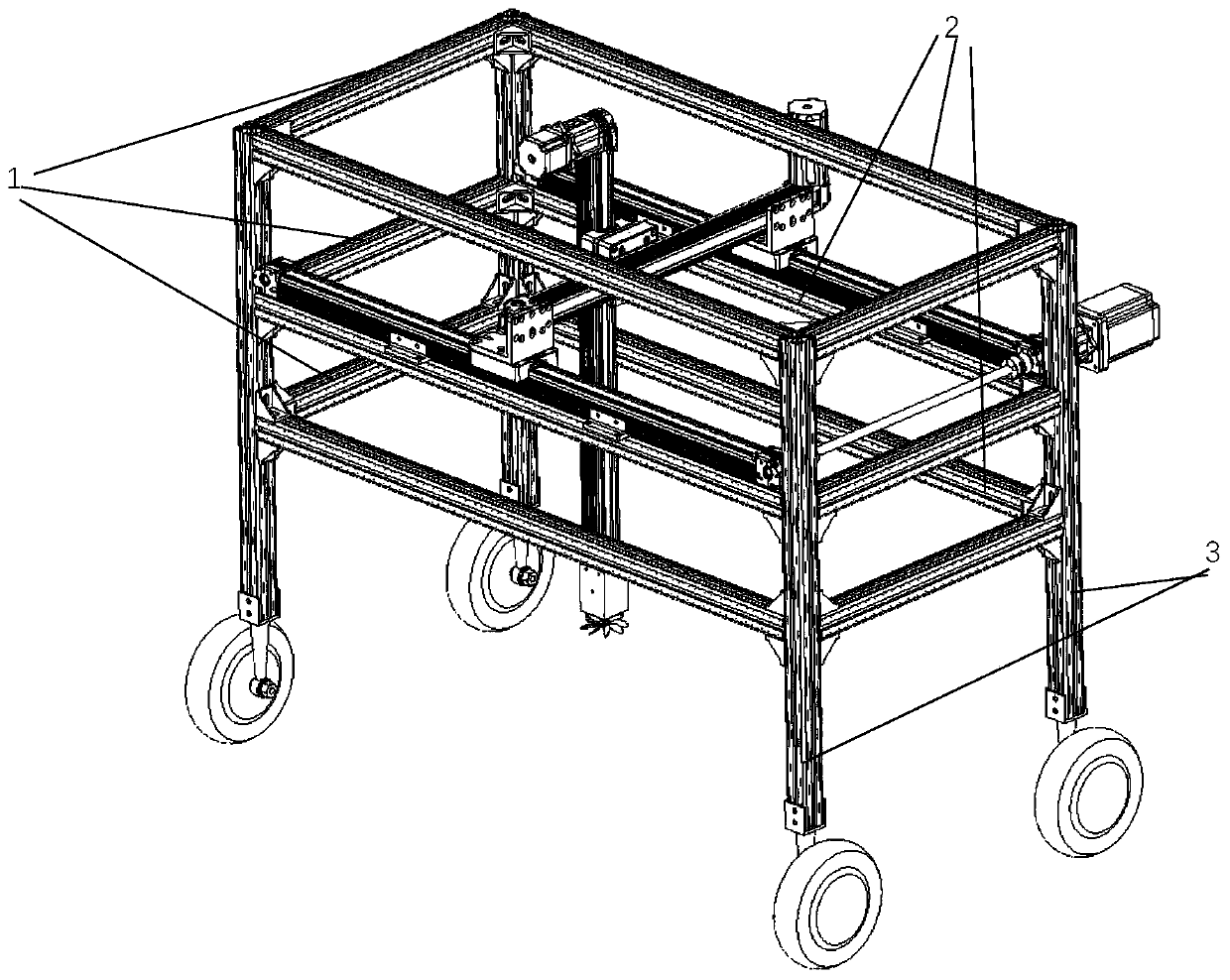

[0020] like figure 1 As shown, a three-coordinate-based mobile greenhouse weeding mechanism includes an overall structural frame, a three-coordinate mobile module, a wheel drive and an execution terminal.

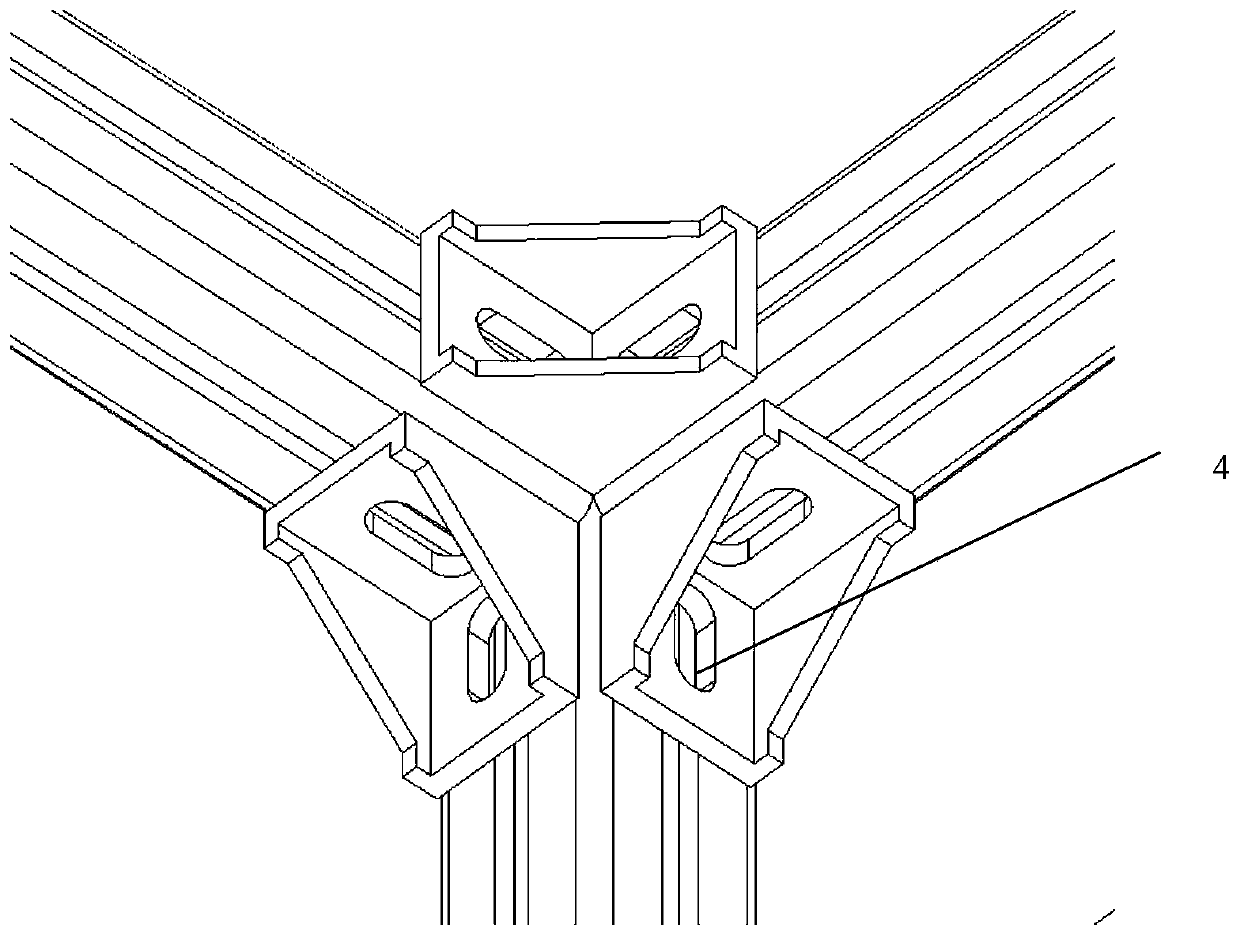

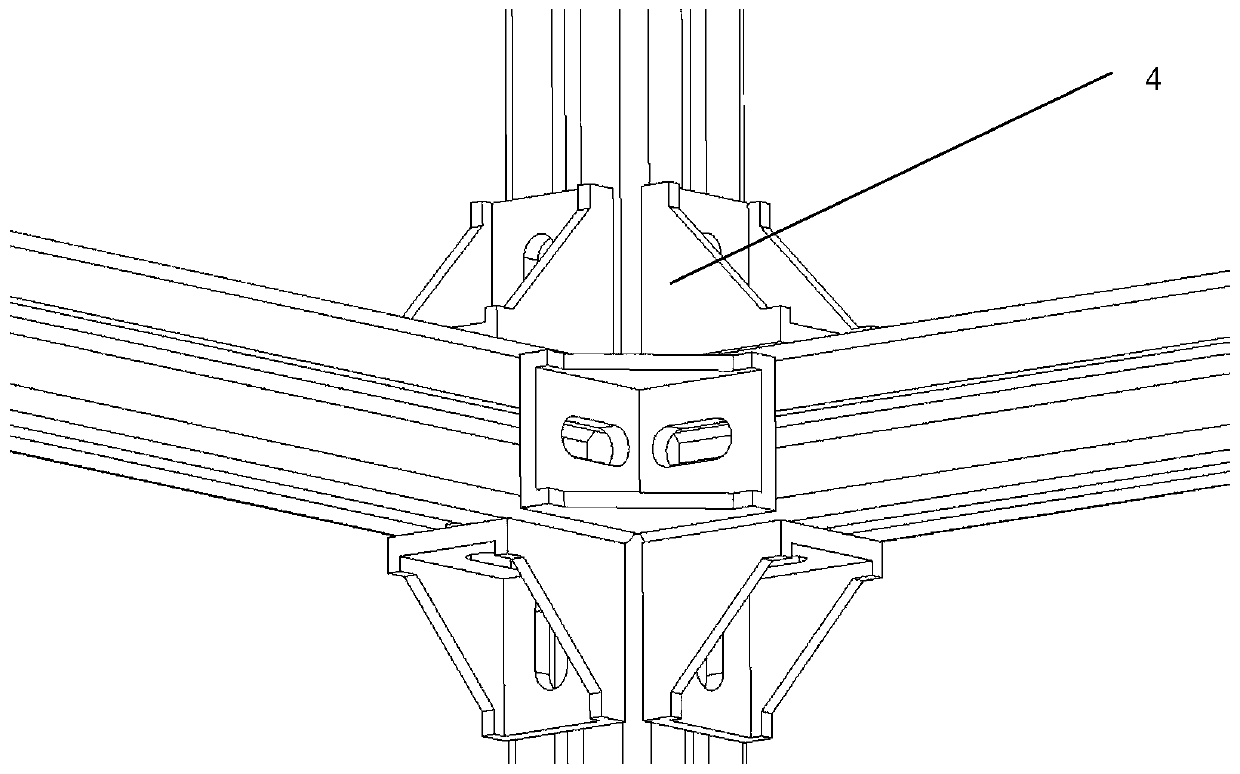

[0021] like Figure 1-3 As shown, the overall structural frame is composed of three lengths of aluminum profiles, consisting of x-direction beam 1 (length 520mm), y-direction beam 2 (length 1100mm) and z-direction longitudinal beam 3 (length 800mm) (three aluminum profiles Sections are 40x40mm). Among them, there are six beams 1 in the x direction, six beams 2 in the y direction, and three beams 3 in the z direction. The x-direction beam and the y-direction beam are divided into three groups, and each group has two x-direction beams and two y-direction beams. Each set of x-direction beams and y-direction beams forms a rectangular beam g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com