Method, device, equipment and storage medium for block cleaning of ship wall area

A wall area and block technology, which is applied in the direction of ship cleaning device, hull, ship construction, etc., can solve the problems that it is difficult to know the cleaning line, the underwater robot is difficult to pass automatically, and the underwater robot is difficult to pass through, so as to ensure the operation The effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

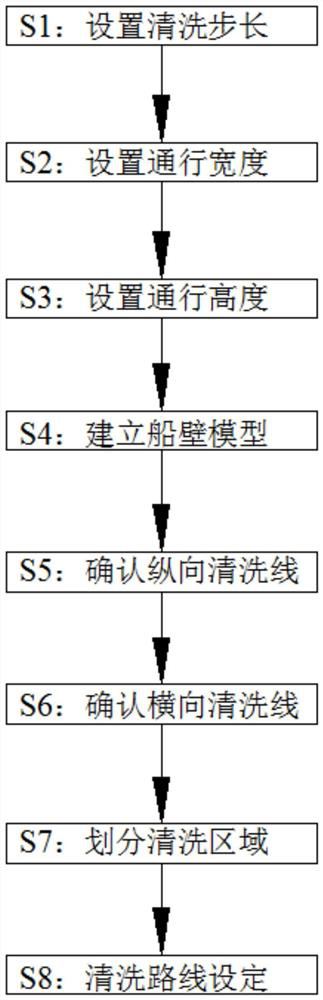

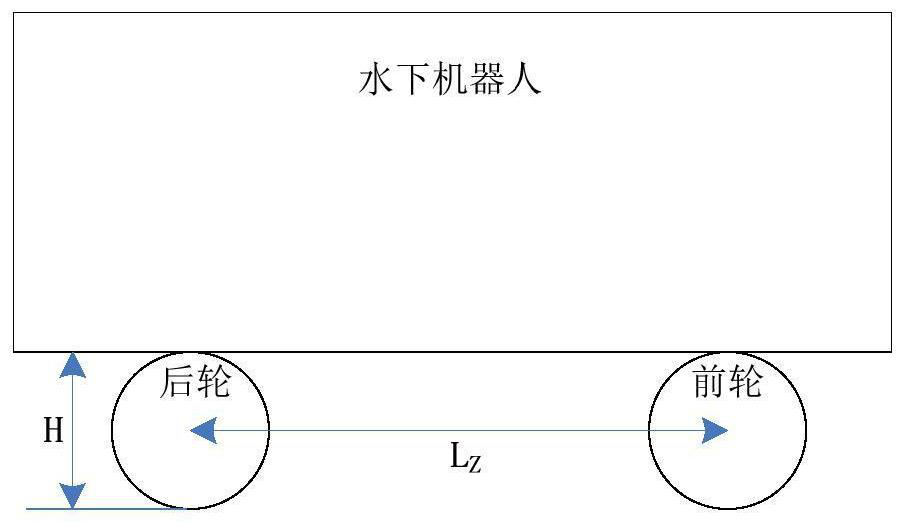

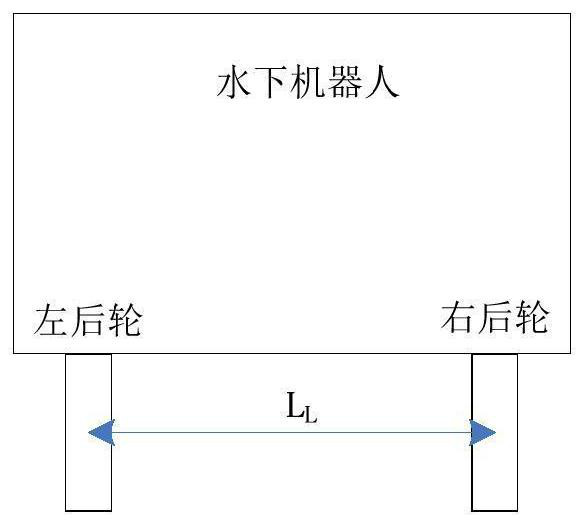

[0048] Such as Figure 1-11 As shown, the block cleaning method of the ship wall area includes the following steps: S1: Set the cleaning step length: define the distance between the front and rear wheel axles of the underwater robot as a cleaning step size, and set the cleaning step size as LZ; S2: Set the traffic width: Define the distance between the left and right wheel axles of the underwater robot as the passage width, and set the passage width as LL; S3: Set the passage height: define the height of the front and rear wheels of the underwater robot as the passage height, and set the passage height as H; S4: Establish the ship wall Model: The underwater robot moves around the ship to be cleaned, photographs and / or scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com