A top drive cementing head

A cementing cement and main body technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc. It can solve problems such as inability to place sealing balls, high risk of operation safety, and single function, so as to ensure operation The effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

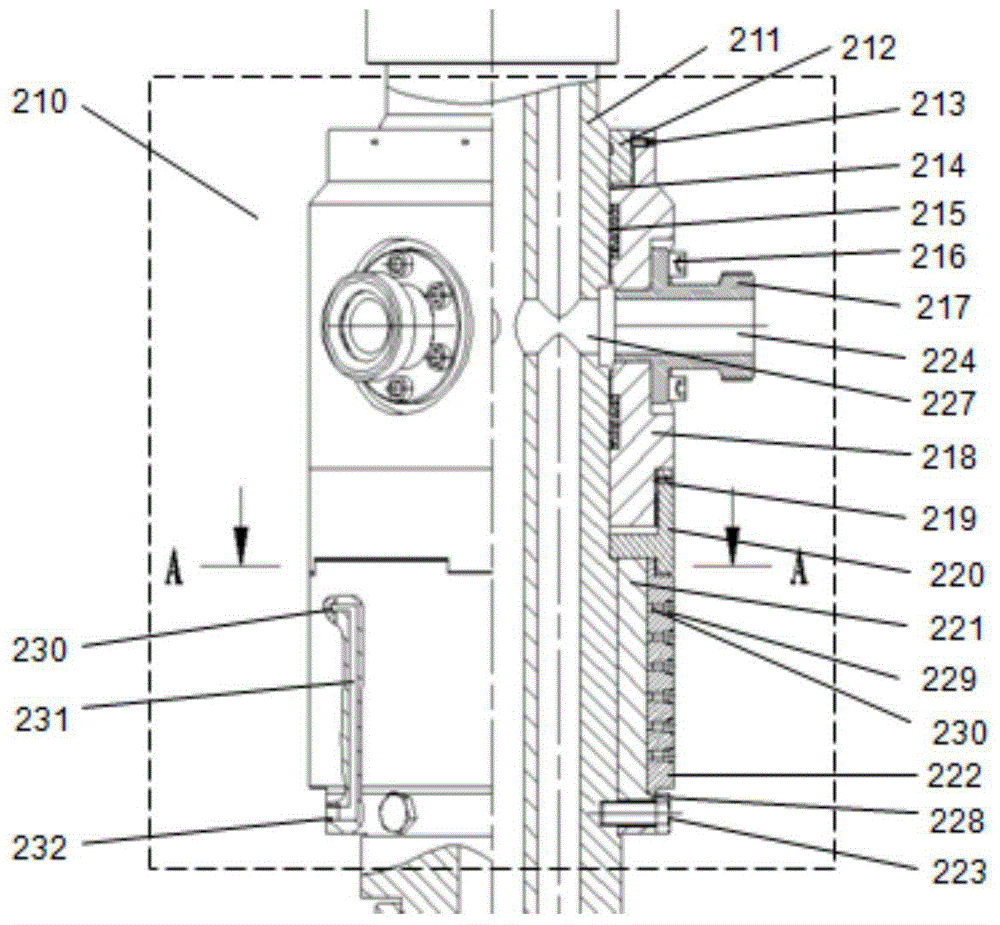

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

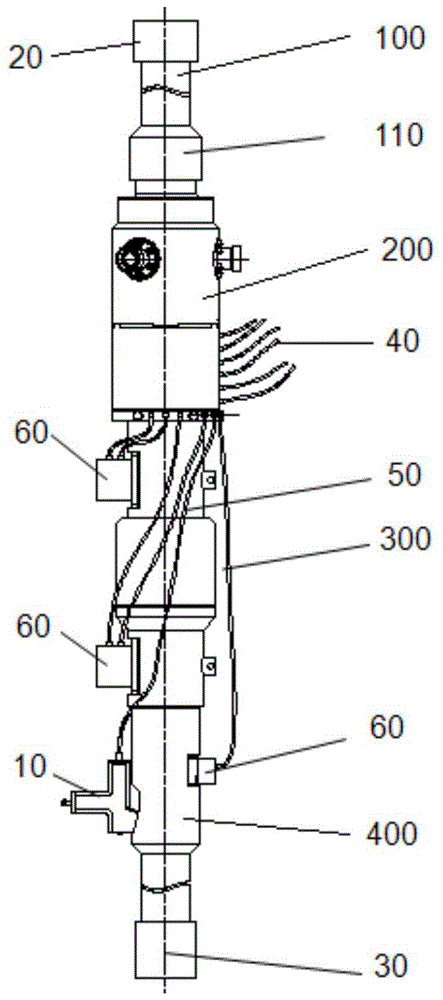

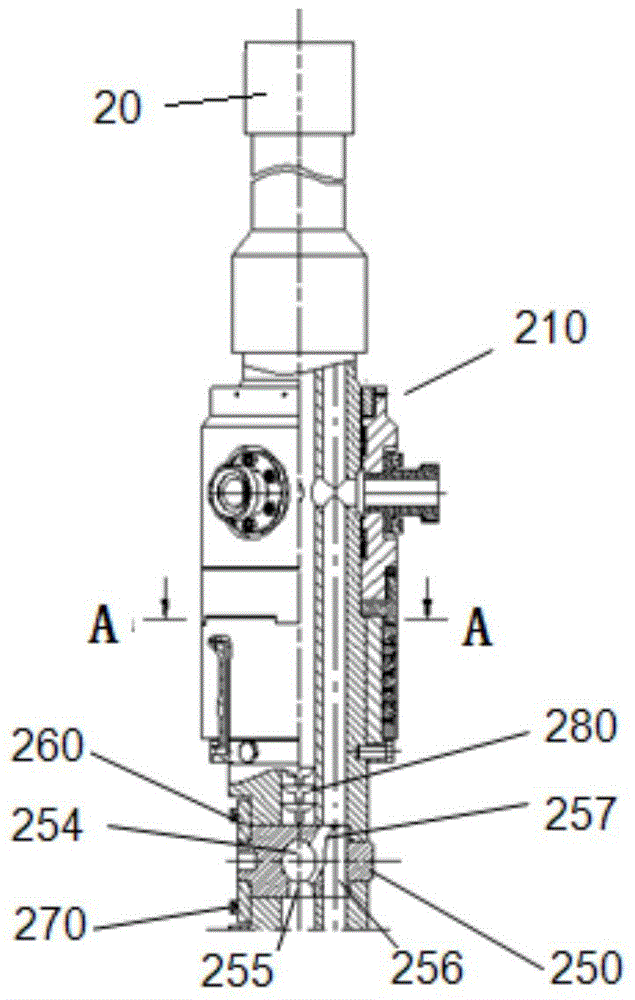

[0033] refer to figure 1 , the overall structure of the device of the present invention is to include an upper joint 100, the upper joint 100 is upwardly connected with the drill pipe pup joint 20 or other lifting tools, the upper joint 100 is downwardly connected with the upper main body assembly 200 through the thread pair A110, and the upper main body assembly The equipment in the assembly 200 is connected to the outside through the air intake pipeline 40, the upper main body assembly 200 is connected downwardly with the lower main body assembly 400 through the quick connection mechanism 300, and the lower main body assembly 400 is connected downwardly with the lowermost drill pipe sub-joint 30 The casing string or other tubular objects extending into the bottom of the well are connected; the upper main body assembly 200 and the lower main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com