Necking inner diameter measurement device and necking inner diameter measurement method of two-piece can

A measuring device and a technology of two-piece cans, which are applied in the field of necking inner diameter measuring devices, can solve problems such as inaccurate measurement data of the inner diameter of the necking, and achieve the effect of avoiding inaccurate measurement data of the inner diameter of the necking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

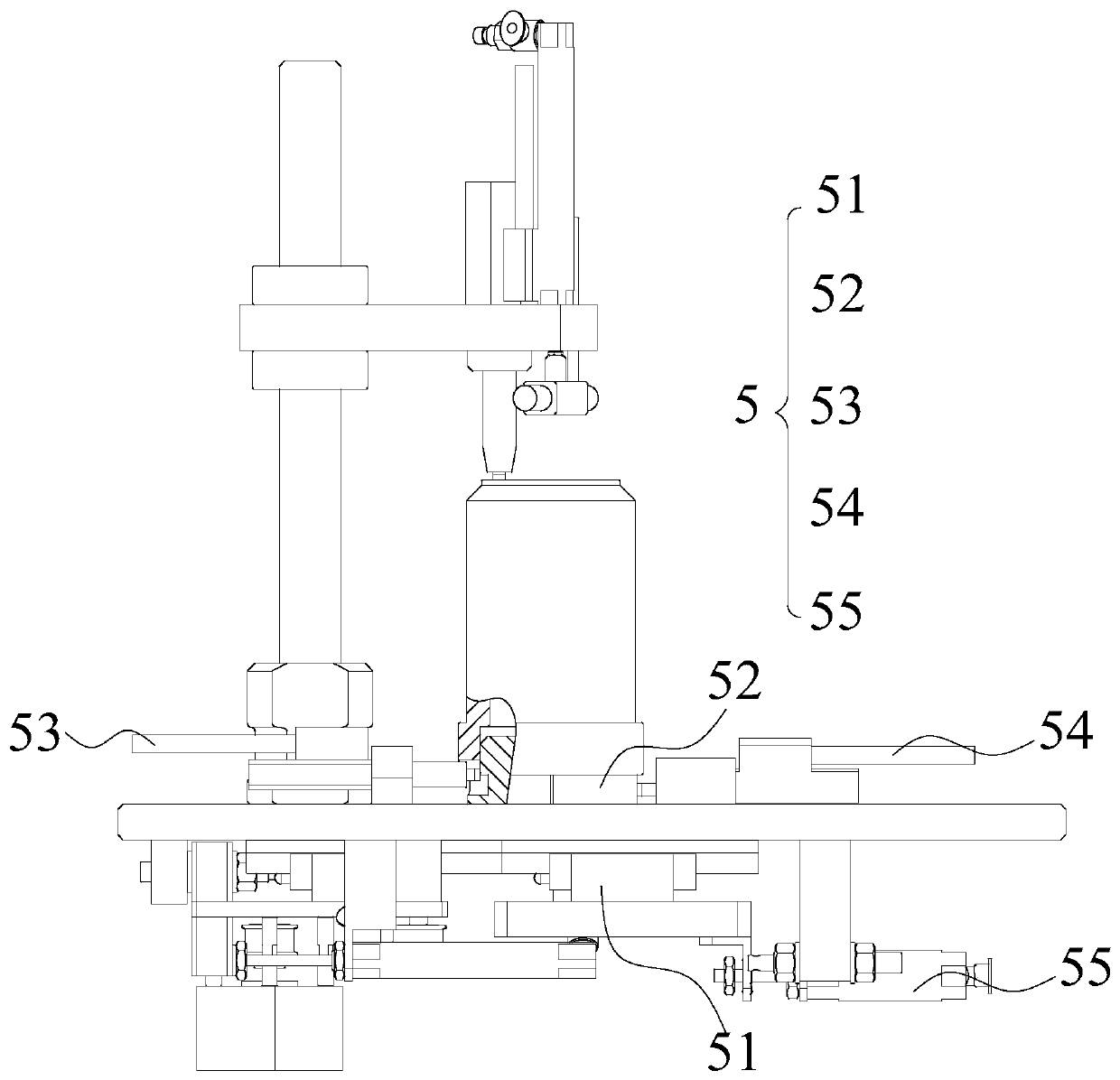

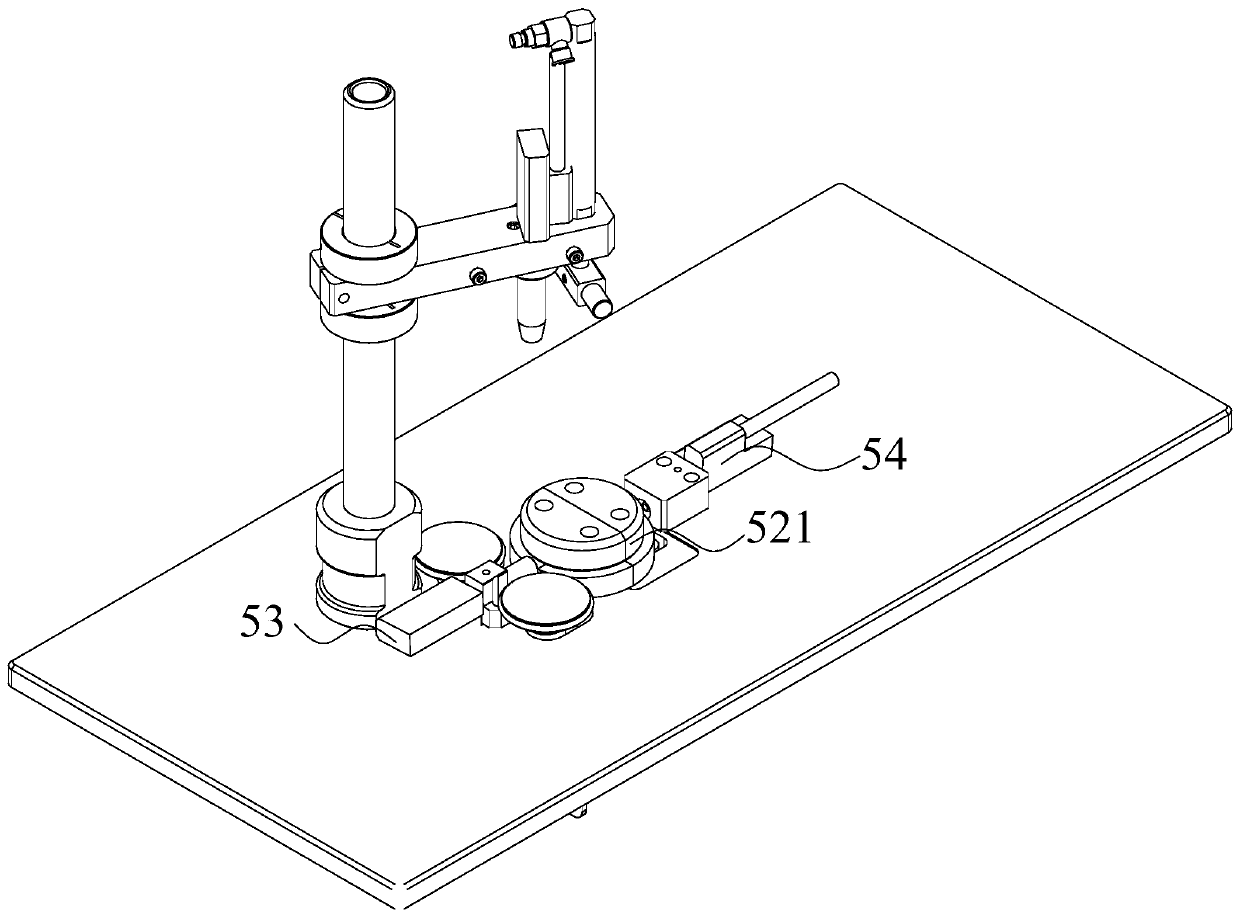

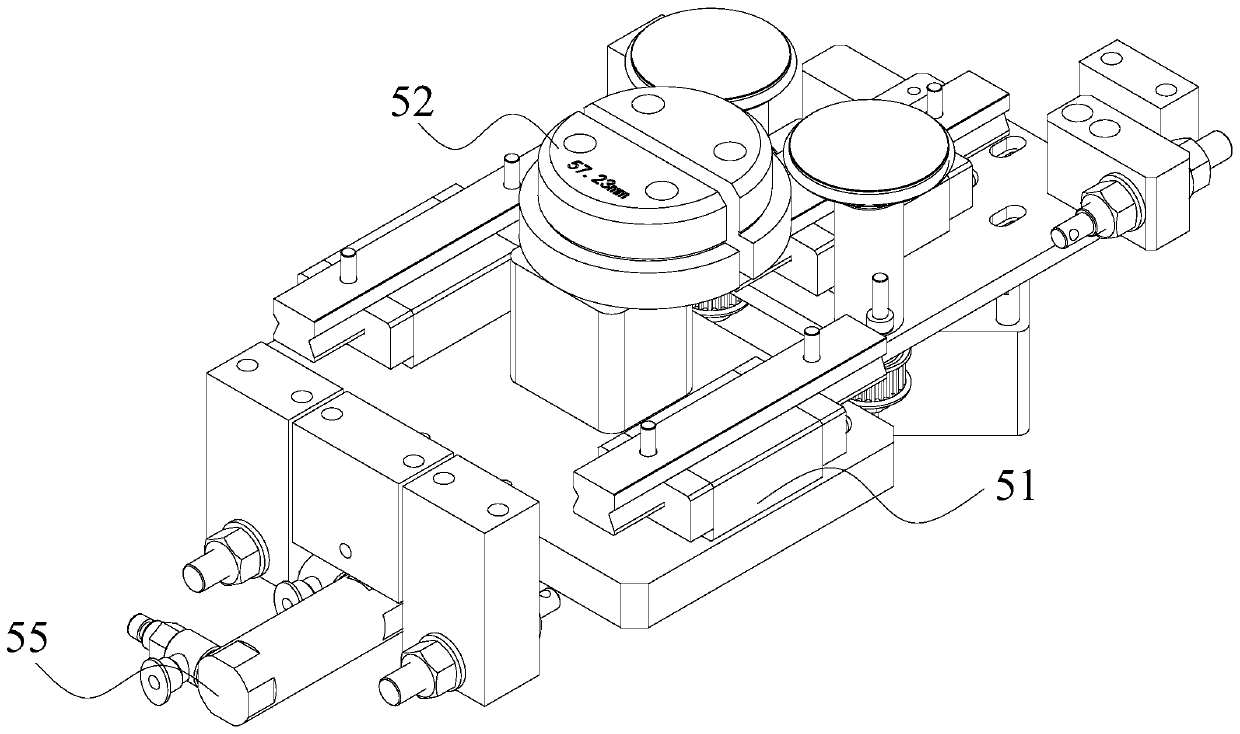

[0032] The necking inner diameter measuring device 5 of the two-piece tank of the present invention is as Figure 1-4 As shown, the necking inner diameter measuring device 5 of a two-piece can includes a linear guide rail 51, a can mouth positioning device 52 slidably mounted on the linear guide rail 51, a flange width measuring probe 53 for detecting the flange width, The constriction internal diameter measurement probe 54 for measuring the constriction internal diameter and the mobile cylinder 55 that provides power, the tank opening positioning device 52 includes two semicircle blocks 521, wherein the left semicircle block 521 is fixedly arranged, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com