A coupling and method for adjusting its stiffness

A coupling and axial technology, applied in the field of rolling stock transmission system, can solve the problem of not meeting the development needs of rail transit vehicles, and achieve the effects of being conducive to later maintenance and replacement, eliminating torsional vibration and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

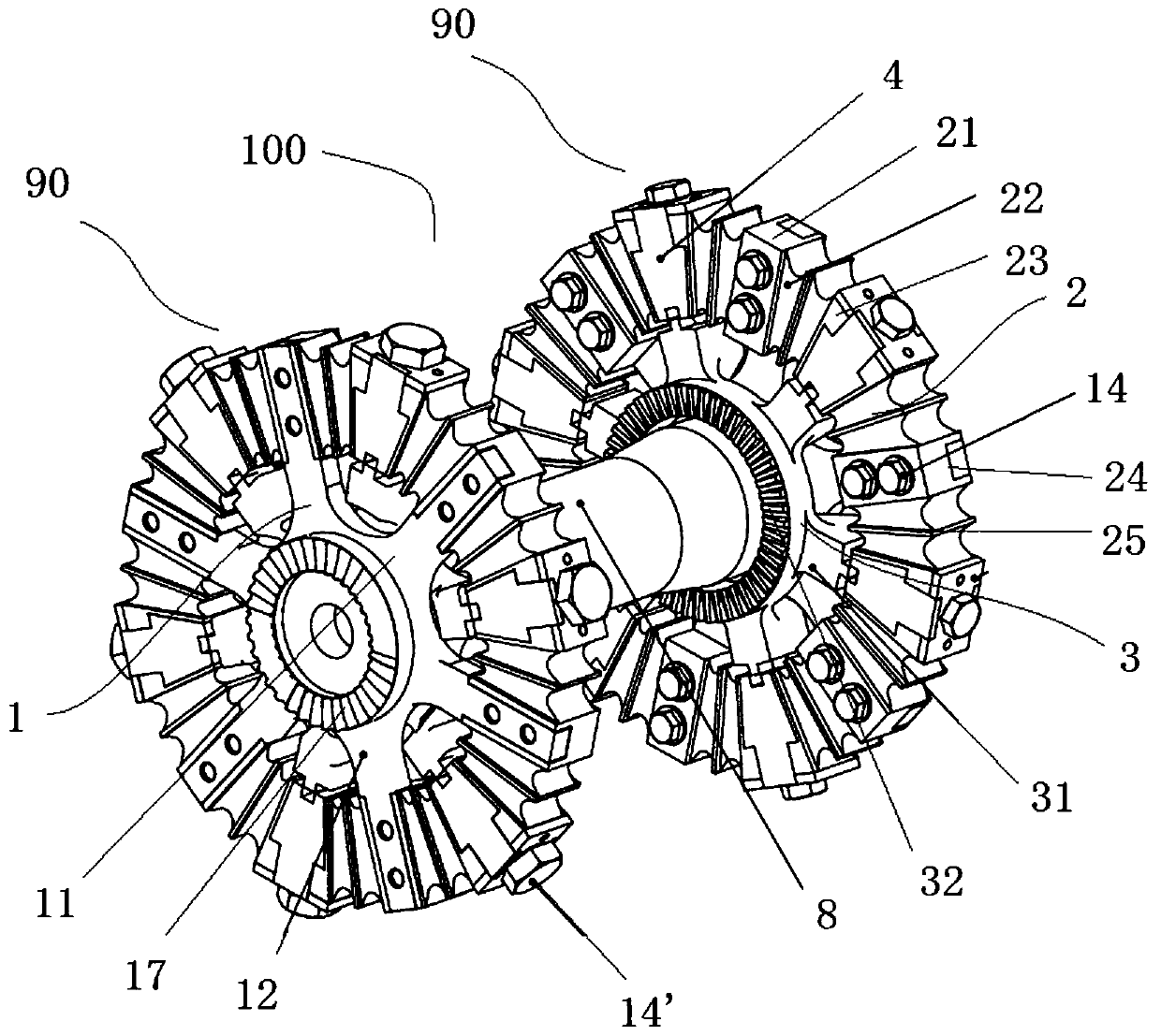

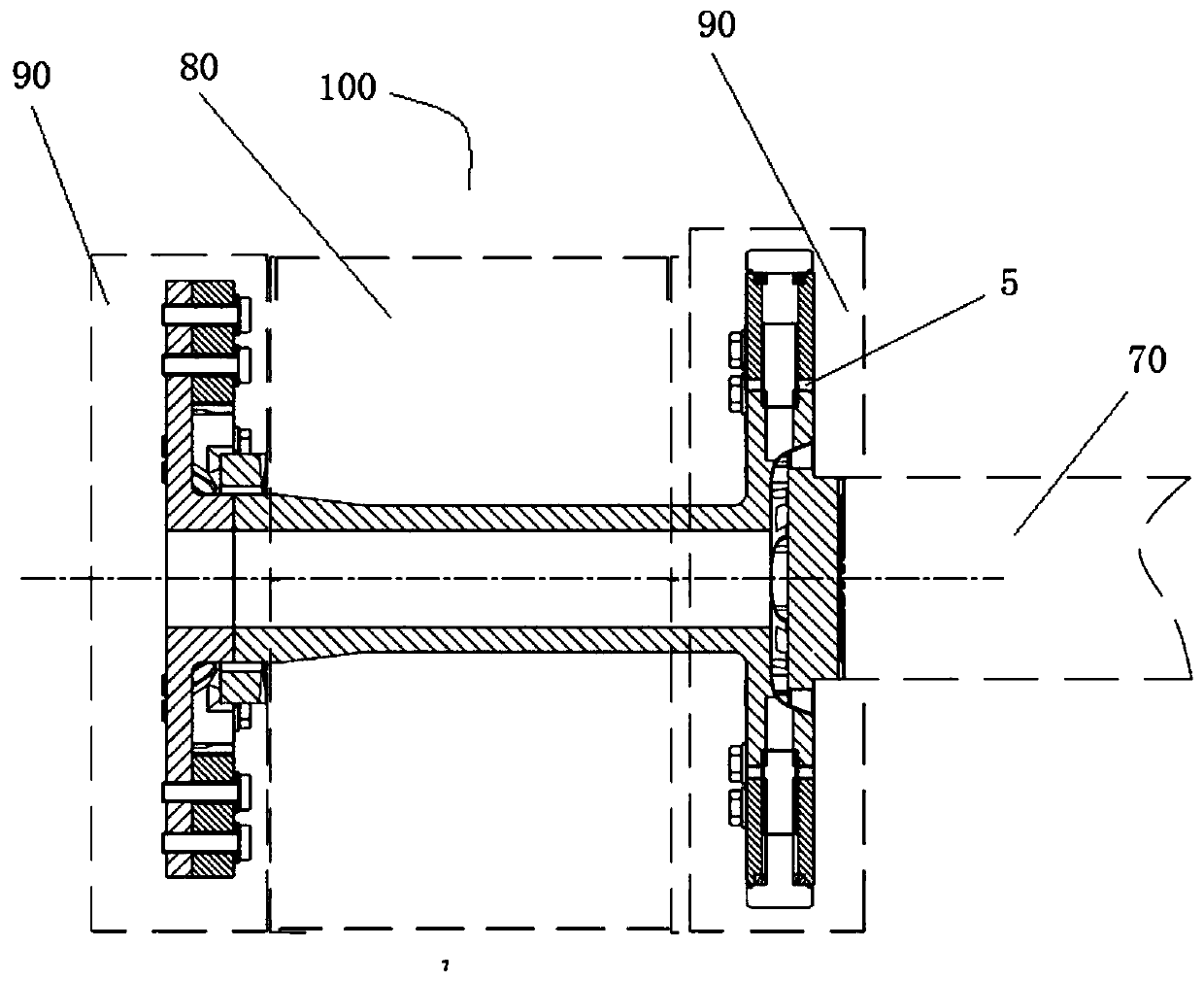

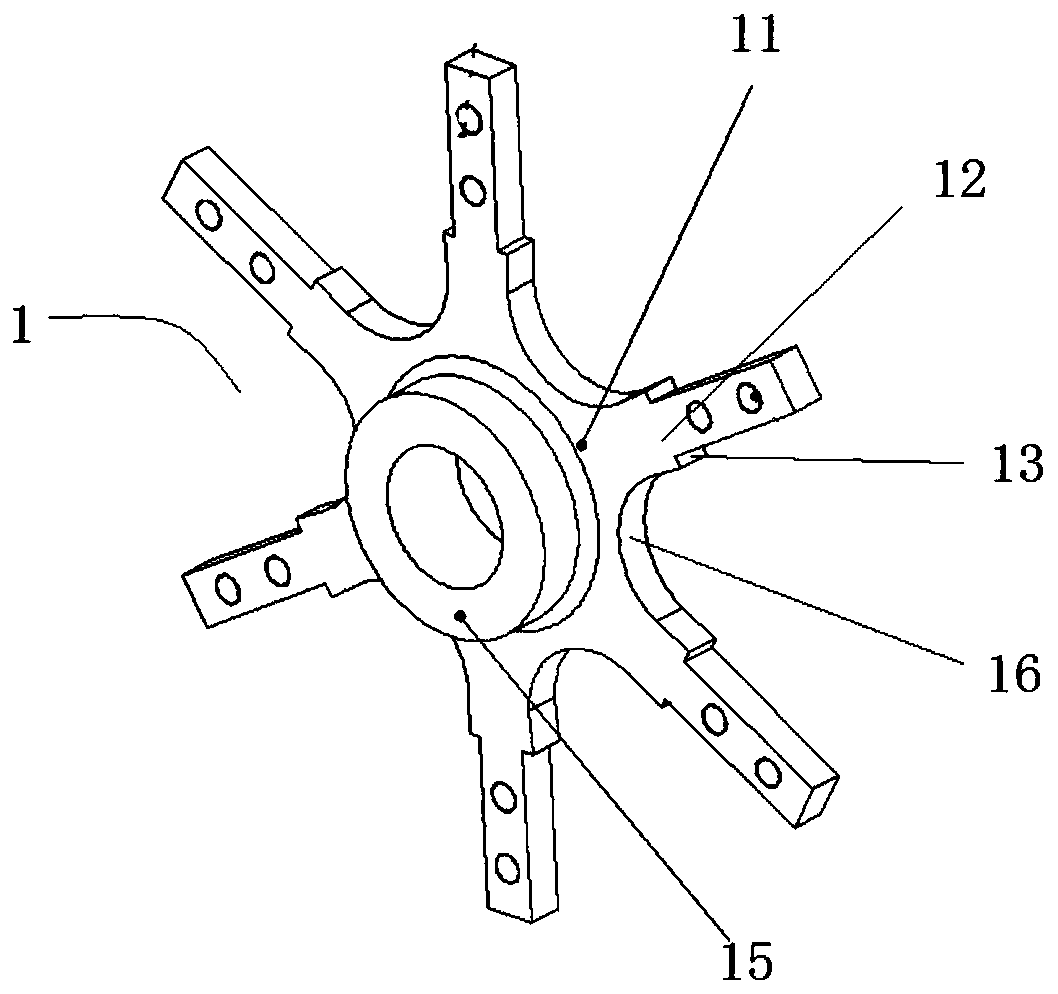

[0040] figure 1 and 2 A coupling 100 according to one embodiment of the invention is shown. like figure 1 and 2 As shown, the coupling 100 includes two elastic body connecting devices 90, and the two elastic body connecting devices 90 are arranged opposite to each other. Specifically, each elastomer connection device 90 has a spider 1 . like image 3 As shown, the spider 1 has a spider main body 11 and a plurality of first arm end bosses 12 . The spider main body 11 is cylindrical. The boss 12 at the first arm end is fixedly connected with the spider main body 11 and extends radially outward. A plurality of bosses 12 at the first arm end are arranged at intervals in the circumferential direction. Fan-shaped elastic elements 2 are correspondingly arranged on each first arm end boss 12 , and the plurality of elastic elements are circumferentially spaced apart.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com