Initiative confining pressure test system suitable for explosives and solid propellant materials

A solid propellant and test system technology, which is used in the test of ammunition, the use of stable tension/pressure to test the strength of materials, and the analysis of materials, etc. problem, to achieve the effect of simultaneous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

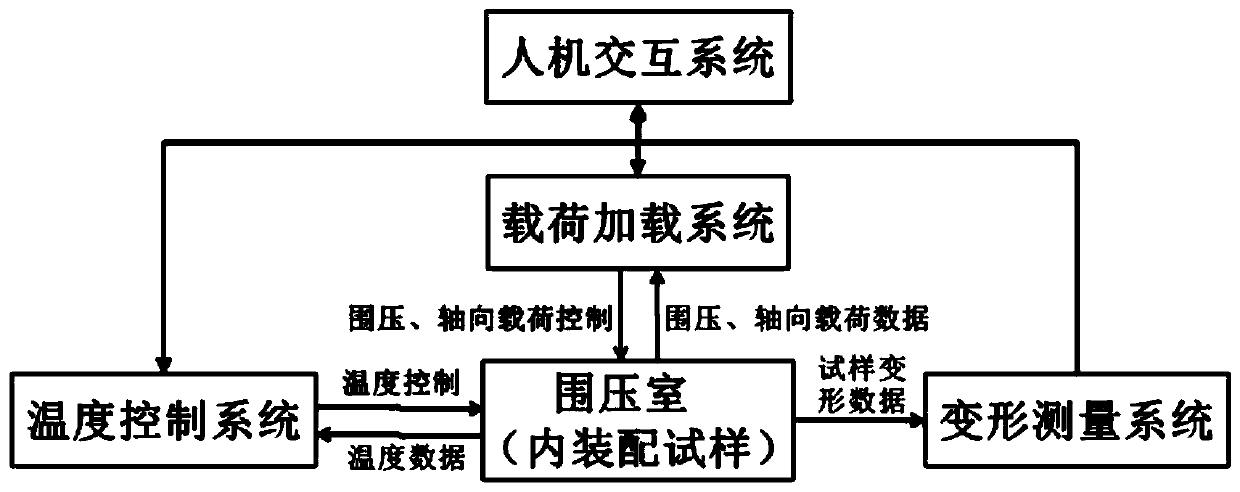

[0010] Such as figure 1 As shown, the present invention provides an active confining pressure test system suitable for explosives and solid propellant materials, the system consists of a load loading system, a deformation measurement system, a temperature control system and a human interaction system, and the load loading system includes a surrounding Pressure loading system and axial loading system. The confining pressure loading system can realize the loading function of the sample confining pressure by hydraulically loading the confining pressure chamber filled with hydraulic oil. The axial loading system can realize the test by replacing the special fixture. The tensile and compressive loading functions of the sample axial direction, the deformation measurement system can realize the synchronous measurement function of the axial and radial deformation of the sample through special tooling, and the temperature control system, by heating the hydraulic oil in the confining pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com