Multi-loop low-voltage track lamp connection mechanism

A connection mechanism and multi-circuit technology, applied in circuit layout, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve problems such as serious glare, heavy workload, time-consuming and laborious, and save disassembly and assembly and closing time, reducing manpower output, and the effect of lighting environment changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

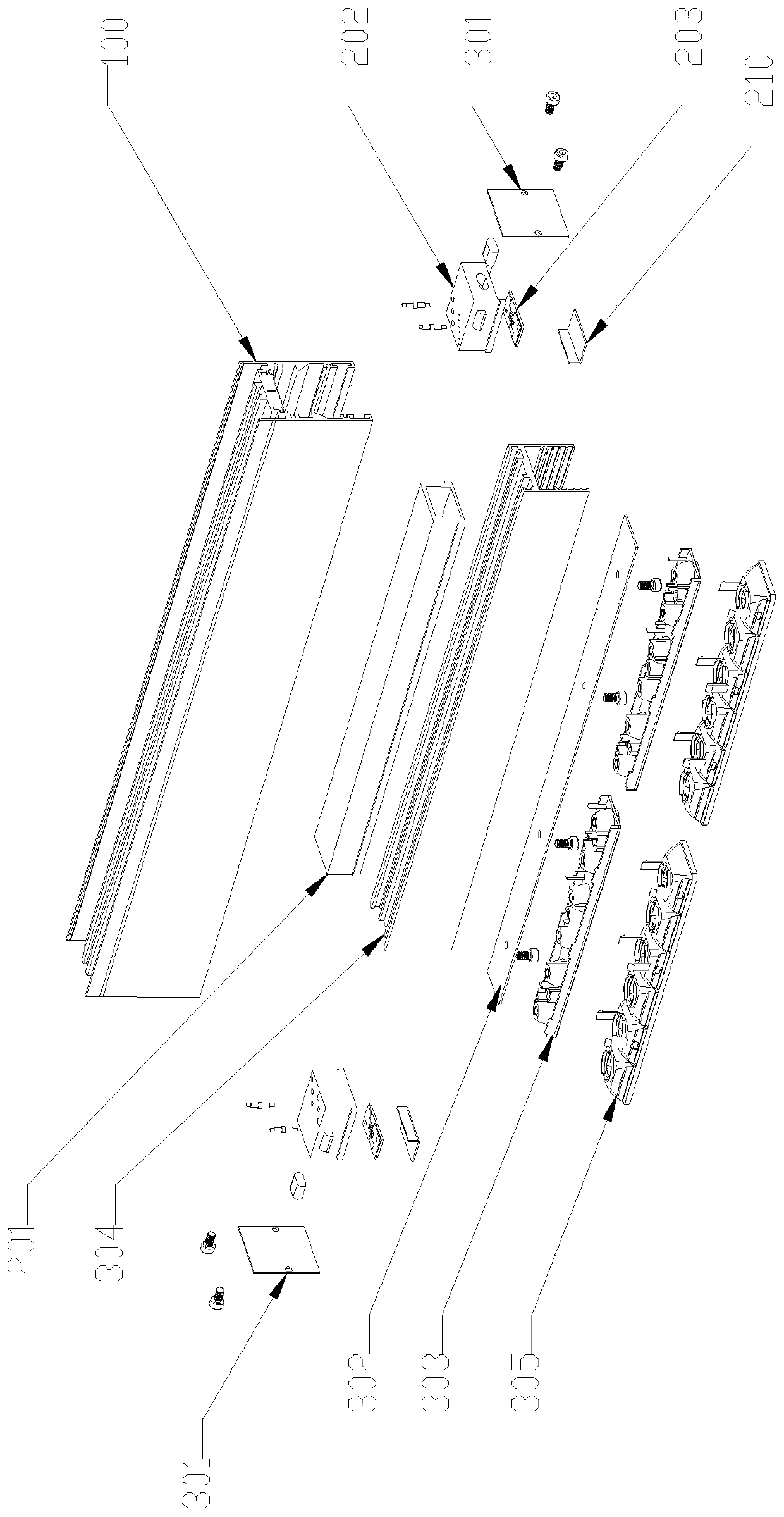

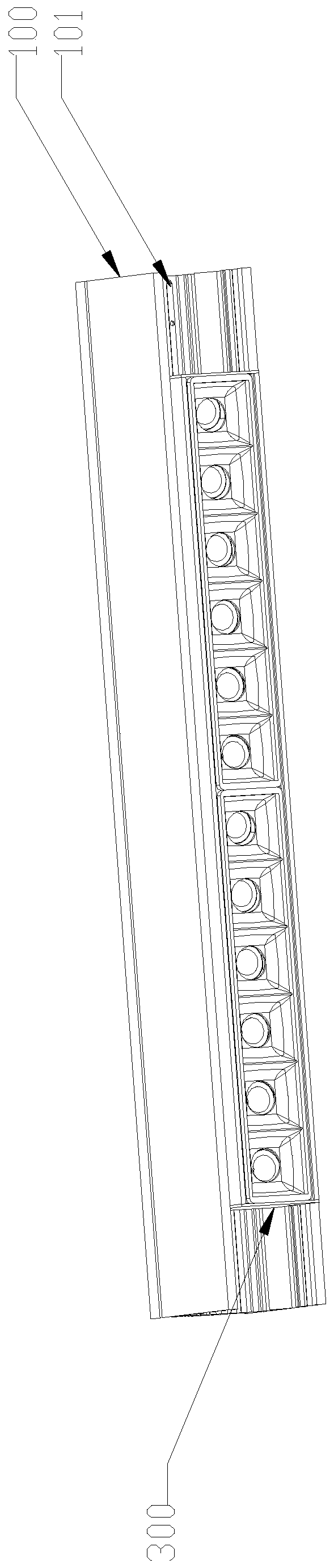

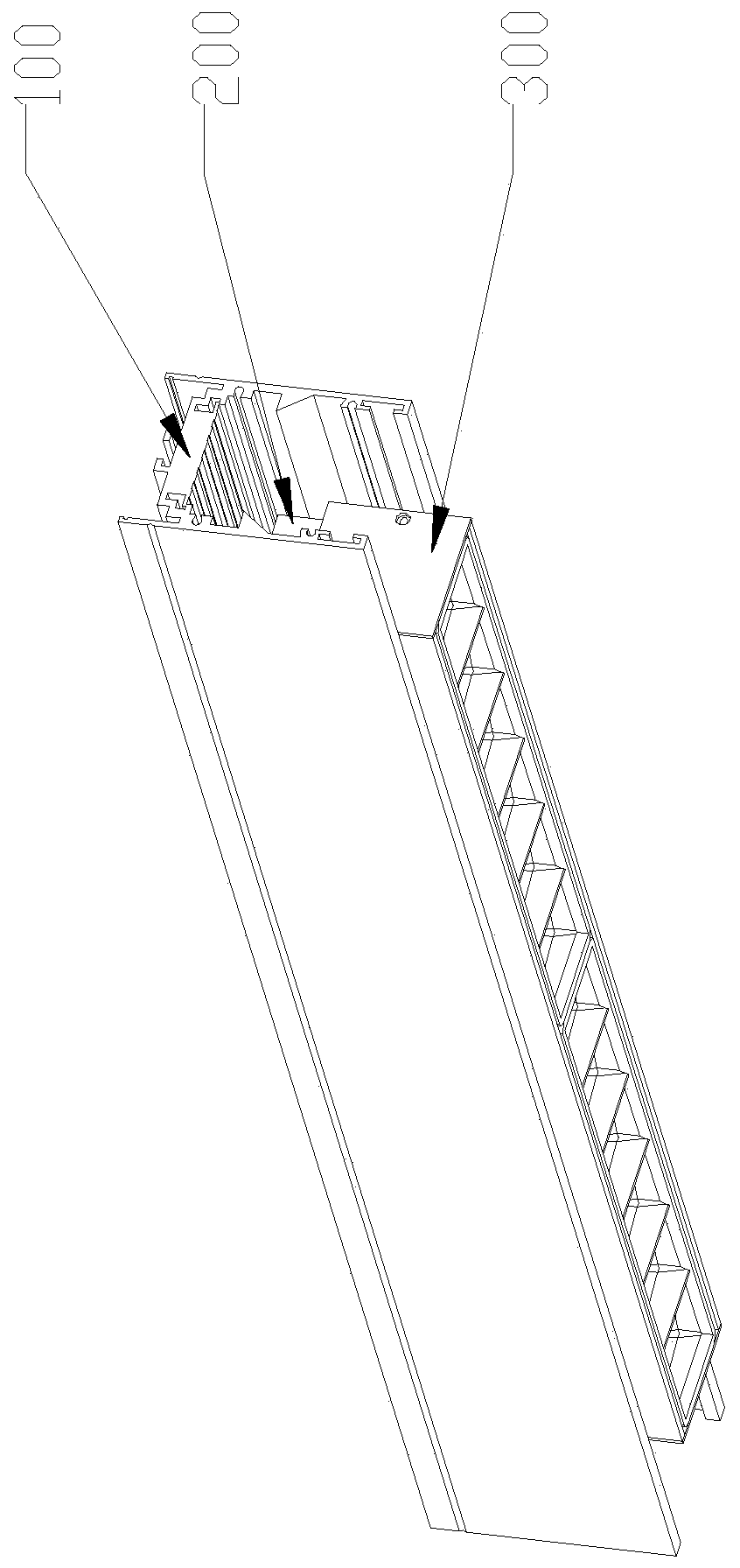

[0042] A connection mechanism for multi-circuit low-voltage track lamps, comprising a track bar 100 , a connecting device 200 and a linear spotlight 300 . The track bar 100 is engaged with the connecting device 200 . The connection device 200 is plugged into the linear spotlight 300 .

[0043] There are at least two or more multi-phase power circuits formed in the track strip 100, and the electrical connection device of the track lamp is provided as a connection circuit option. Six conductive copper sheets 101 and six energized input lines are arranged on the inner top of the track bar 100 along its length. The six energized input lines include three positive input terminals 102 and three negative input terminals 103 arranged in parallel. The positive input end 102 contacts the positive conductive column 104 . The negative input terminal 103 is in contact with the negative conductive column 105 .

[0044] The connection device 200 includes a baffle fixing block 201 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com