Display panel and preparation method thereof and display device

A technology for display panels and array substrates, applied in nonlinear optics, instruments, optics, etc., can solve problems such as frame limitation and thickness increase, and achieve the effect of reducing frame width, reducing the risk of wire breakage, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

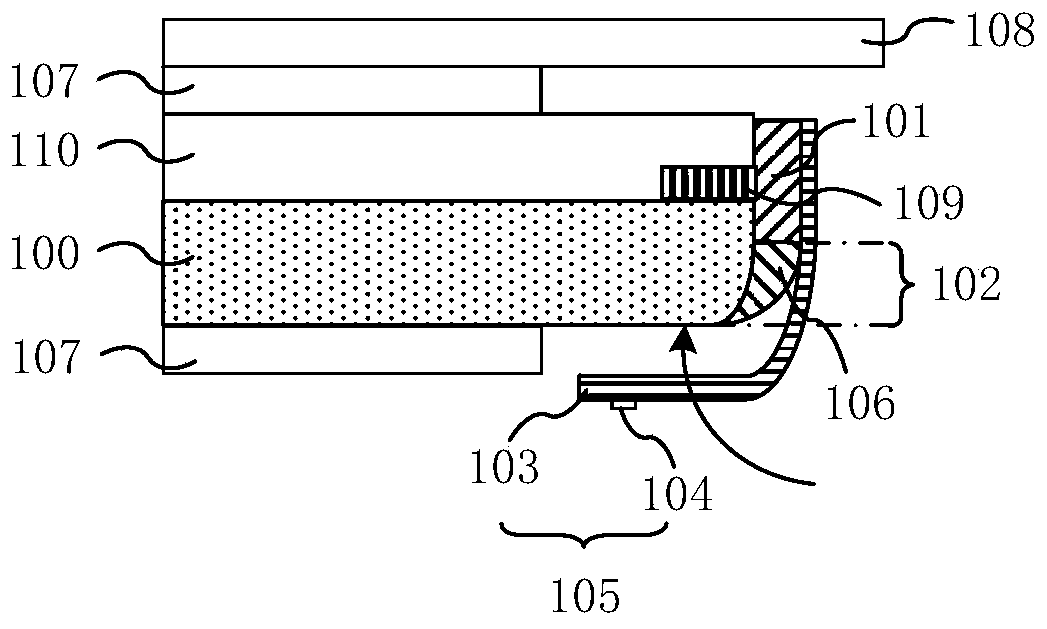

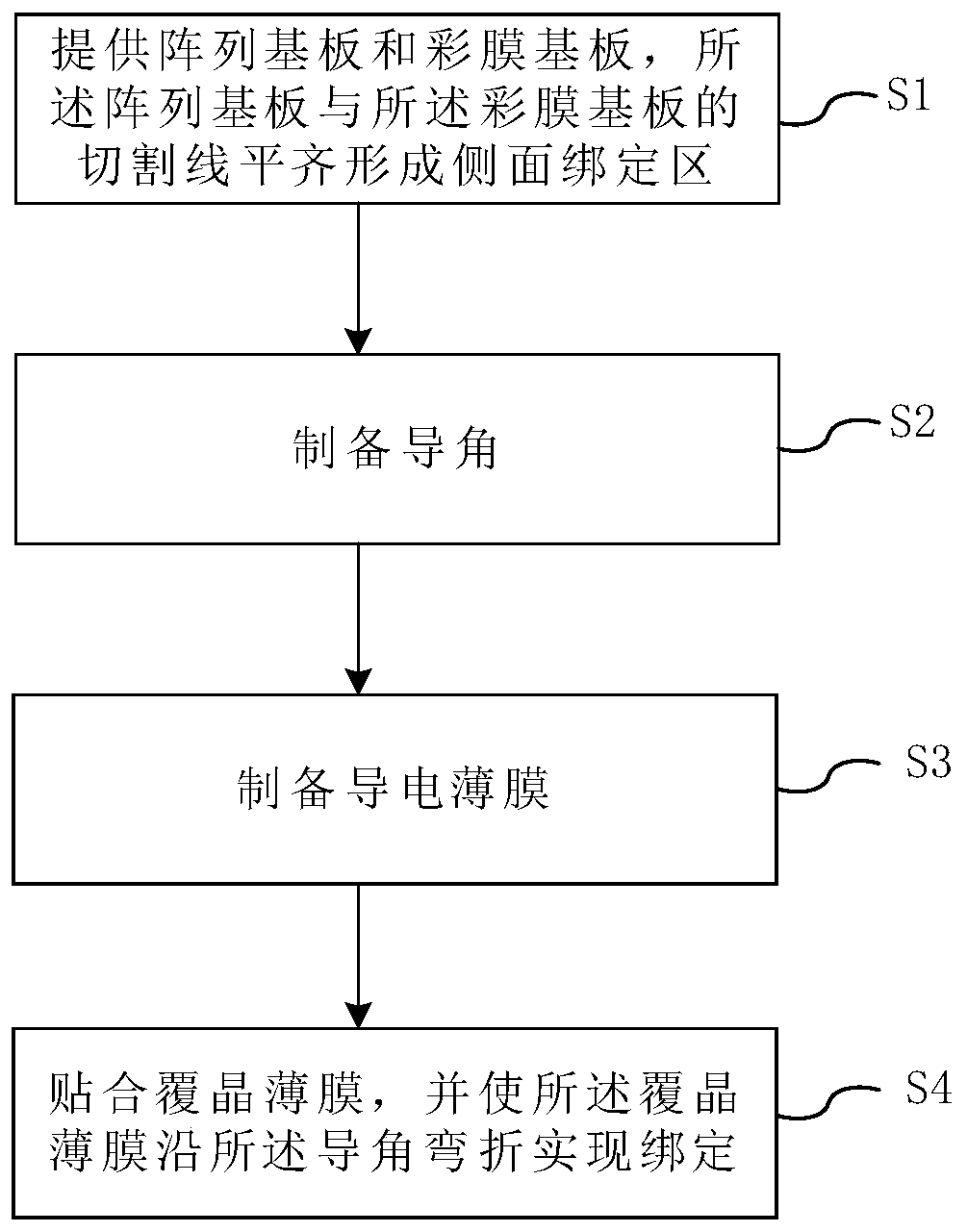

[0038] like Figure 1A Shown is a schematic structural view of the display panel of the present invention; the display panel includes an array substrate 100, and a color filter substrate 110 opposite to the array substrate 100; The upper and lower polarizers 107 at the bottom; the package cover 108 . In addition, the display panel also includes liquid crystal molecules disposed between the color filter substrate 110 and the array substrate 100 , a back film disposed at the bottom of the panel and other parts not shown.

[0039] like Figure 1A The schematic structural diagram of the display panel shown is mainly the non-display area of the display panel, and the display area of the display panel is not shown in the drawing. refer to Figure 1A It can be seen that the side of the array substrate 100 is flush with the side of the color filter substrate 110 to form a side binding area, and the side binding area is located between the array substrate 100 and the color filter s...

Embodiment 2

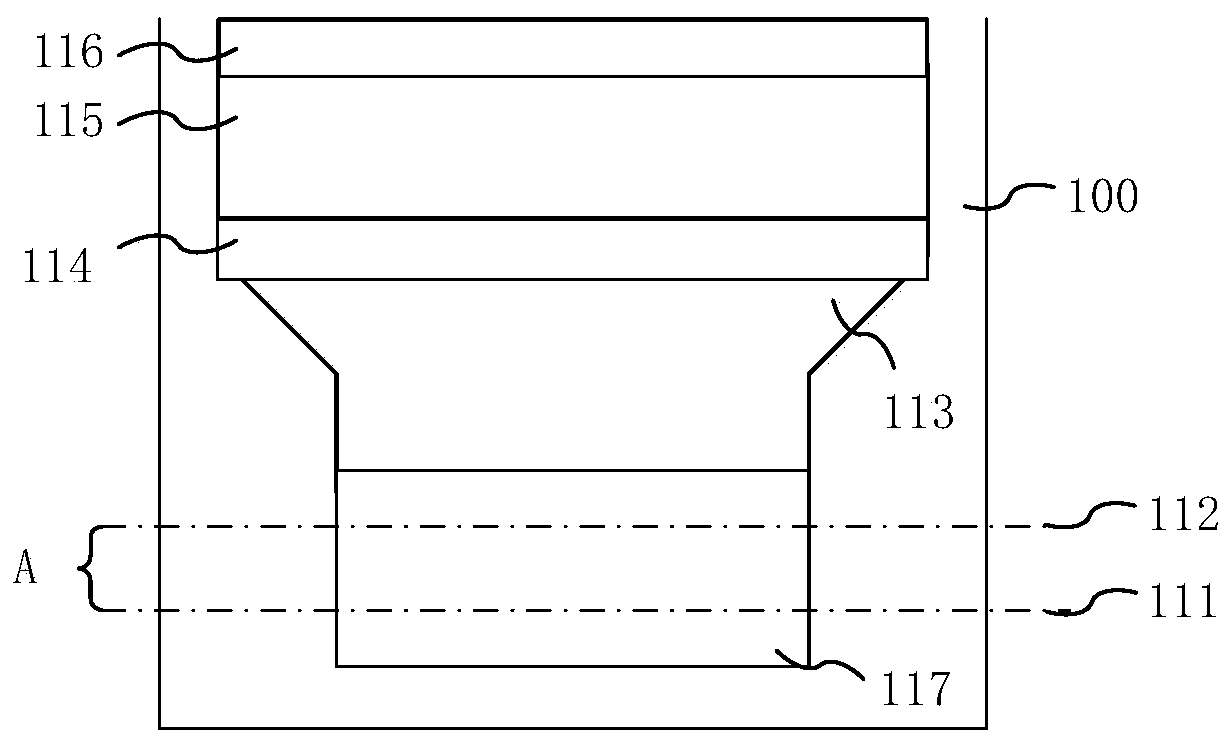

[0055] like image 3 Shown is a schematic diagram of another display panel structure, and the marks in the figure are the same as Figure 1A The marks in are the same and will not be repeated here. Depend on image 3 It can be known that the array substrate 100 is flush with the cutting line of the color filter substrate 110 to form a side binding area, the conductive film 101 is arranged in the side binding area, and the chamfer 102 is arranged in the color filter substrate 110. On the side of the film substrate 110 , the COF film 105 is bent along the chamfer 102 and bound to the side of the color filter substrate 110 away from the array substrate 100 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com