Machine -level protection materials are meticulously simulated fixed devices

A technology of protective material and fixing device, which is applied in the field of ablation simulation fixing device of protective material between engine stages, can solve the problems such as difficulty in simulating and observing pulses of double-pulse engine II, and achieves a simple structure, easy assembly, and strong universality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

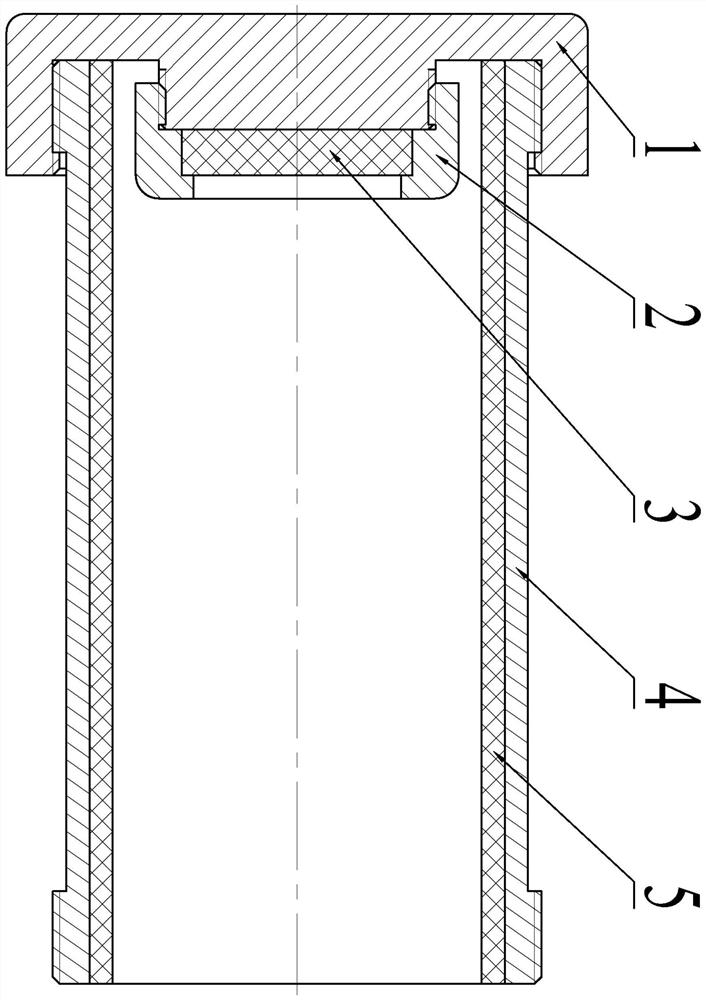

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] combine figure 1 , an engine interstage protective material ablation simulation fixture, which is used to study the mass transfer and heat transfer ablation process of thermal insulation materials, and has important reference value for the design of engine thermal protection structures.

[0018] The device includes a plug cover 1 , a test piece fixing end cover 2 , a test piece 3 , an engine casing 4 and an inner liner 5 .

[0019] The 45 steel material used for the blocking cover 1, the fixed end cover 2 of the test piece and the engine casing 4 is used to ensure the strength and meet the requirements of long-term operation of the dual-pulse engine; the lining 5 is made of EPDM rubber material, Its purpose is to flame retardant and heat insulation to avoid the shell temperature being too high.

[0020] combine figure 1 , the blocking cover 1, the test piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com