A production line intelligent inspection system

A technology of intelligent inspection and production line, applied in the field of inspection system, can solve the problems that are not suitable for manual inspection, and achieve the effect of ensuring the efficiency, safety and reliability of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

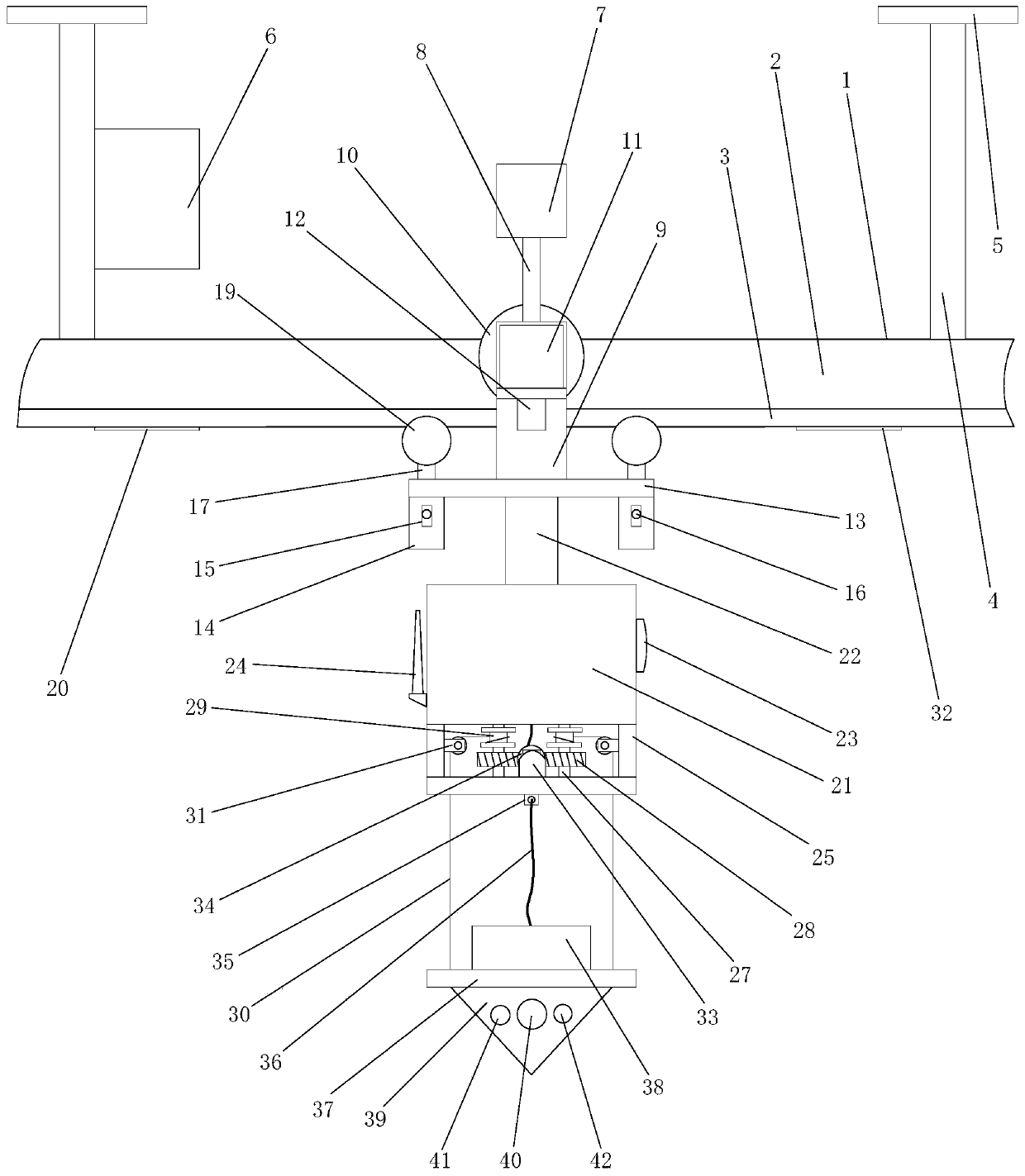

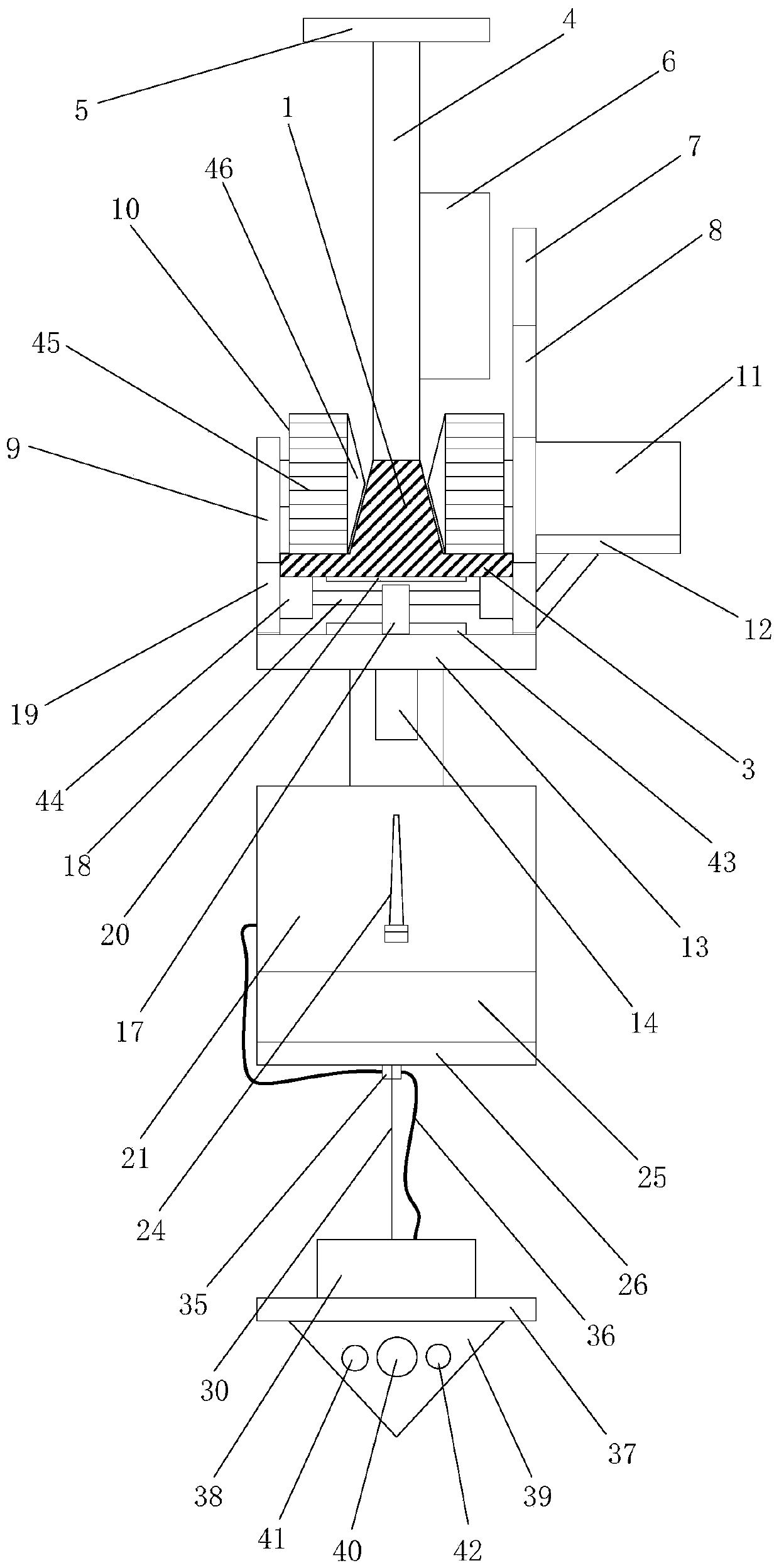

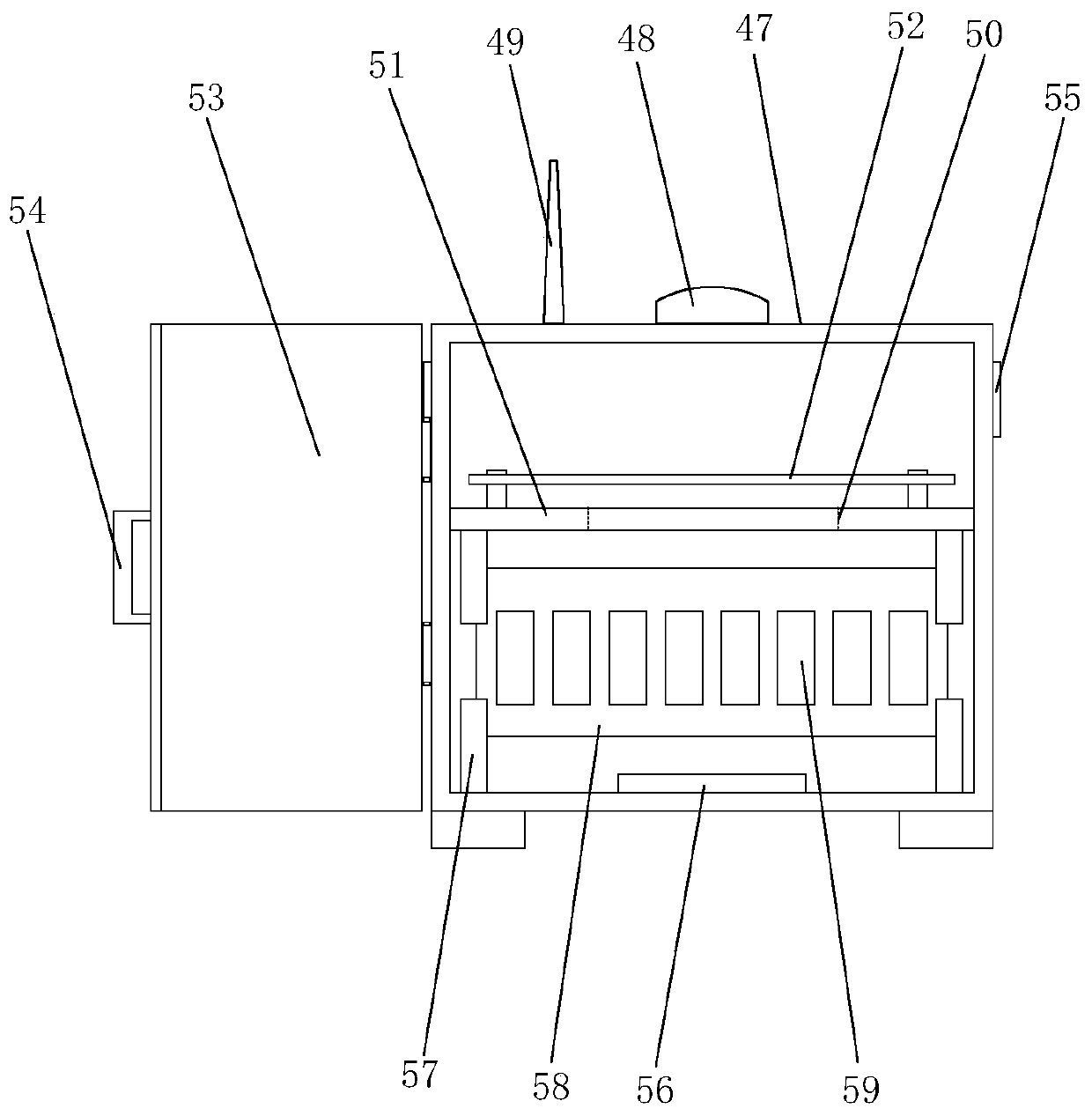

[0025] Such as Figure 1-4 As shown, the production line intelligent inspection system disclosed in the present invention includes: inspection track 1, inspection trolley and central control cabinet 47; Sensitive head 39;

[0026] Vertical suspension rods 4 are arranged at intervals on the upper side of the inspection track 1, and a top mounting plate 5 is provided on the top of the vertical suspension rod 4; the inspection track 1 is a closed-loop track, and the inspection route is a loop route;

[0027] The mobile mounting mechanism is mounted on the inspection track 1 and walks along the inspection track 1; the top center of the control box 21 is suspended and installed on the mobile mounting mechanism through the mounting tube 22; the steel rope lifting mechanism is installed on the control box On the lower side of 21, the quadrangular pyramid sensing head 39 is installed on the suspension end of the steel rope lifting mechanism, which drives the quadrangular pyramid sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com