A special workbench for engineering cost

A project cost and workbench technology, applied in applications, home appliances, legs of general furniture, etc., can solve the problems of wasting time, wasting energy, and inconvenient recording.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

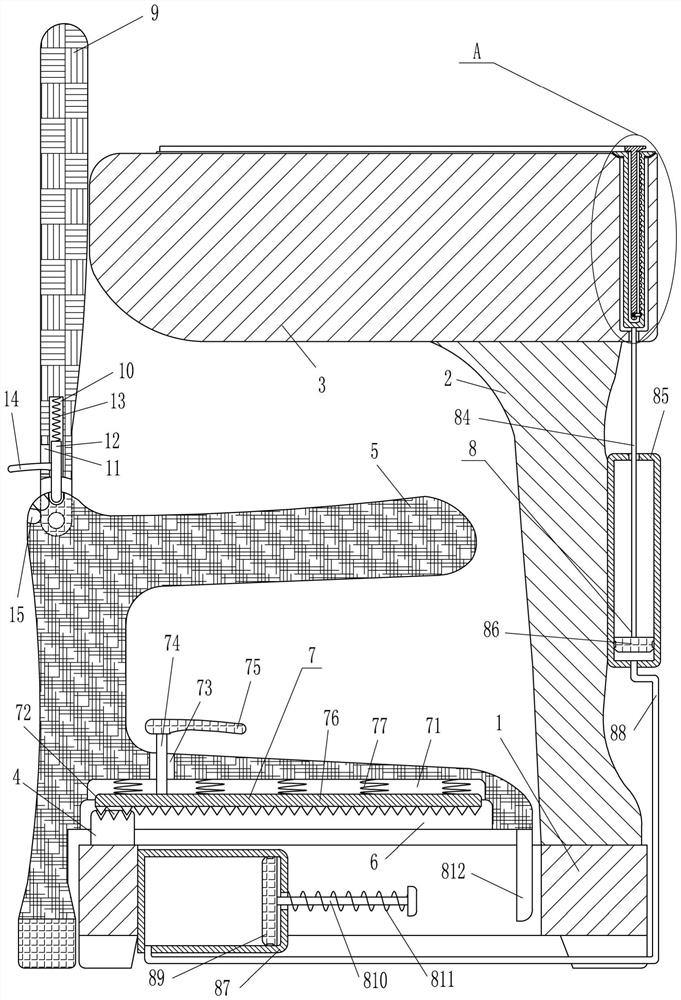

[0016] A special workbench for engineering cost, such as figure 1 As shown, it includes a back-shaped base 1, a support plate 2, a table plate 3, a slider 4, a seat cushion 5 and a clamping device 7, and the top right side of the back-shaped base 1 is provided with a support plate 2, and the back-shaped base 1 is welded The connection method is connected with the support plate 2, the top of the support plate 2 is provided with a table plate 3, and the front and rear parts on the left side of the top of the back-shaped base 1 are provided with sliders 4, and the back-shaped base 1 is connected with the slider 4 by welding There are chute 6 on the front and rear sides of the right bottom of the seat cushion 5, the slider 4 is located in the chute 6, the seat cushion 5 is located above the return-shaped base 1, and a clamping device is provided between the seat cushion 5 and the chute 6 7.

Embodiment 2

[0018] A special workbench for engineering cost, such as figure 1 As shown, it includes a return-shaped base 1, a support plate 2, a table plate 3, a slider 4, a seat cushion 5 and a clamping device 7, a support plate 2 is provided on the right side of the top of the return-shaped base 1, and a Table board 3, slide block 4 is arranged on both front and rear parts on the left side of the top of the back-shaped base 1, and chute 6 is provided on the front and rear sides of the bottom right side of the seat cushion 5, the slide block 4 is located in the chute 6, and the seat cushion 5 is located on the A clamping device 7 is provided between the seat cushion 5 and the chute 6 above the return-shaped base 1 .

[0019] The clamping device 7 includes a slide bar 74, a handle 75, a tooth plate 76 and a first spring 77, the top of the chute 6 has a first opening 71, the top of the slider 4 has a clamping hole 72, and the bottom of the seat cushion 5 has an opening. There are two open...

Embodiment 3

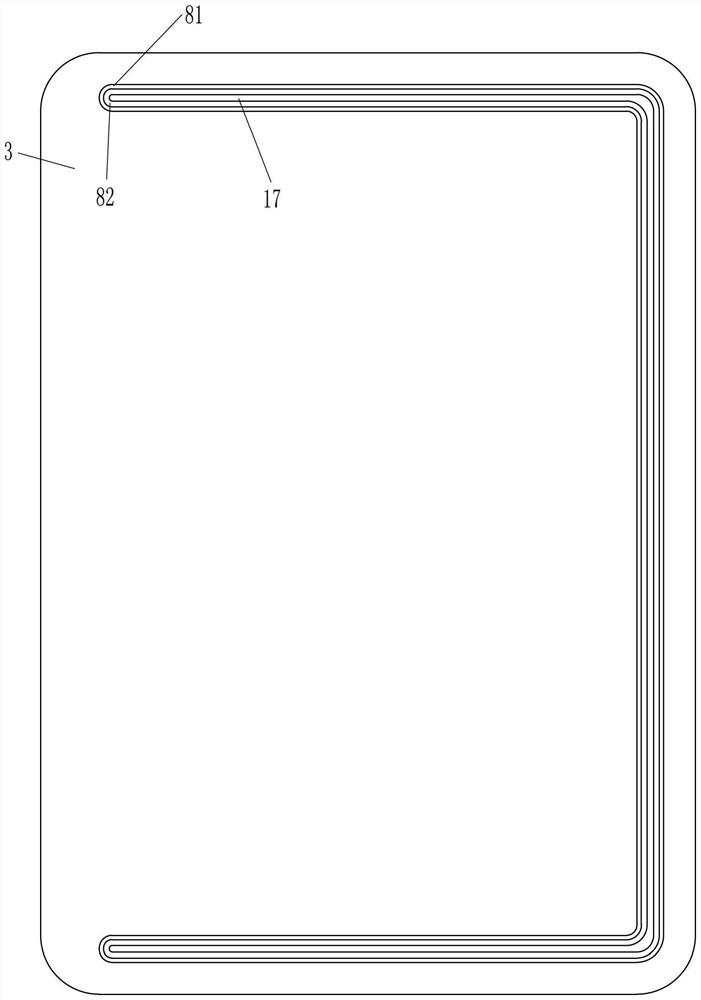

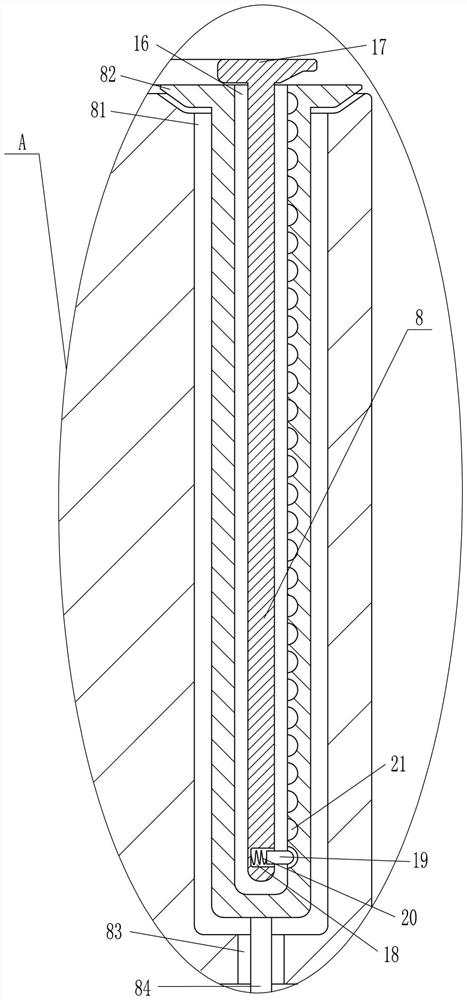

[0021] A special workbench for engineering cost, such as Figure 1-3 As shown, it includes a return-shaped base 1, a support plate 2, a table plate 3, a slider 4, a seat cushion 5 and a clamping device 7, a support plate 2 is provided on the right side of the top of the return-shaped base 1, and a Table board 3, slide block 4 is arranged on both front and rear parts on the left side of the top of the back-shaped base 1, and chute 6 is provided on the front and rear sides of the bottom right side of the seat cushion 5, the slide block 4 is located in the chute 6, and the seat cushion 5 is located on the A clamping device 7 is provided between the seat cushion 5 and the chute 6 above the return-shaped base 1 .

[0022] The clamping device 7 includes a slide bar 74, a handle 75, a tooth plate 76 and a first spring 77, the top of the chute 6 has a first opening 71, the top of the slider 4 has a clamping hole 72, and the bottom of the seat cushion 5 has an opening. There are two o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com