Backrest tilting mechanism of seat function frame

A functional frame and backrest technology, which is applied to chairs, other seating furniture, stools, etc., can solve the problems of laborious recovery and unsmooth operation, and achieve the effect of easy tilting, smooth running, and smooth tilting and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0041] The directional words such as "front", "rear", "left" and "right" involved in this embodiment are described by the user's field of view after the user sits on the seat. For example, the front of the user is "Front"; for better understanding of this embodiment, the connection line A, connection line B, and connection line C involved are virtual lines.

Embodiment

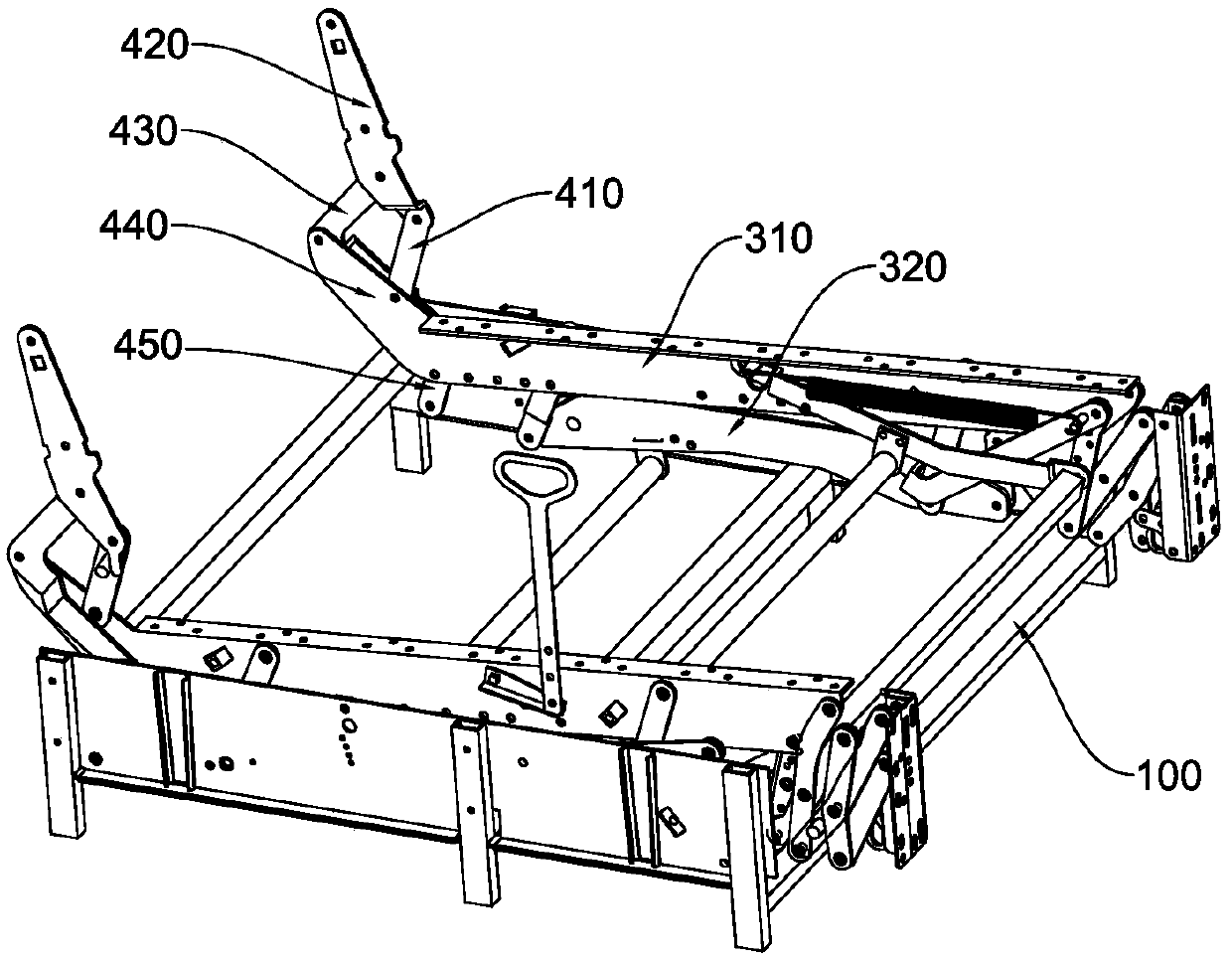

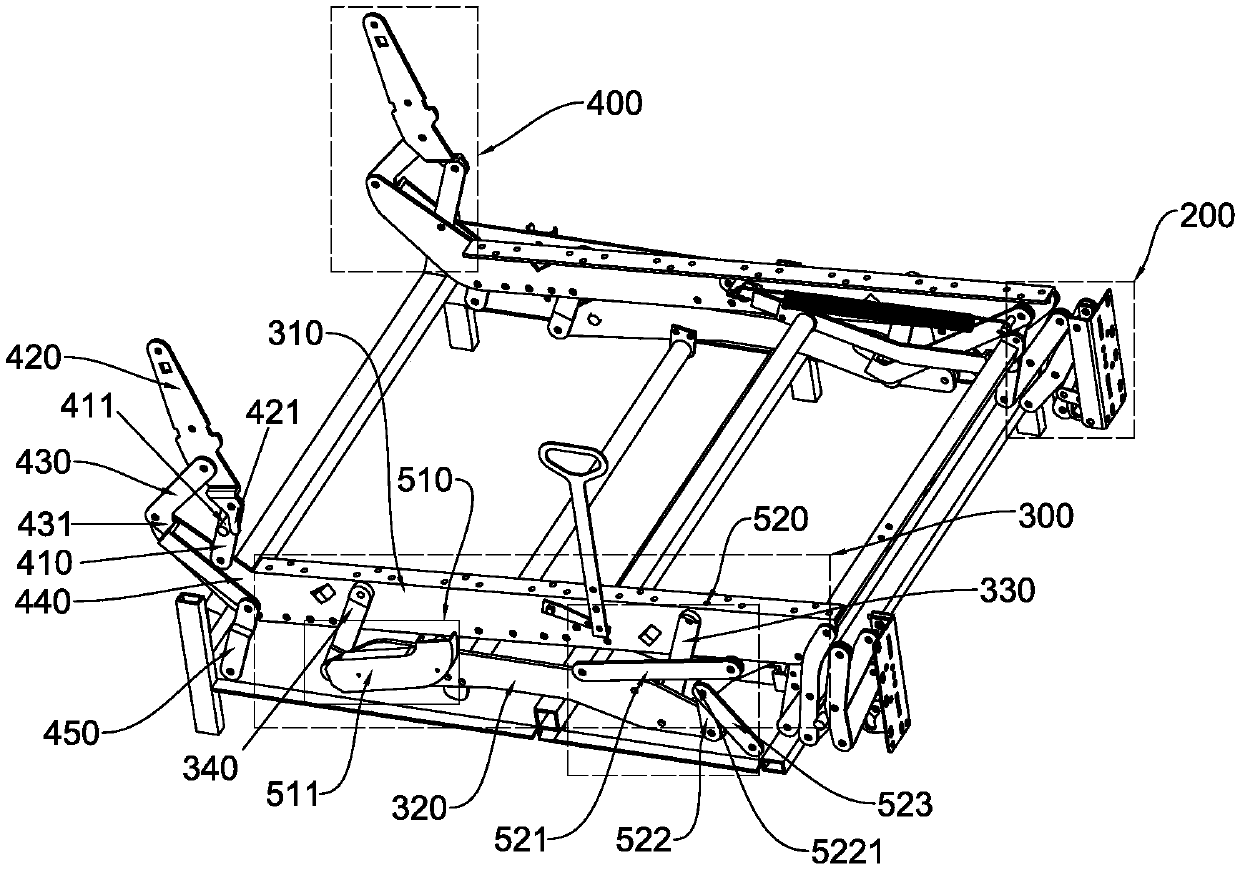

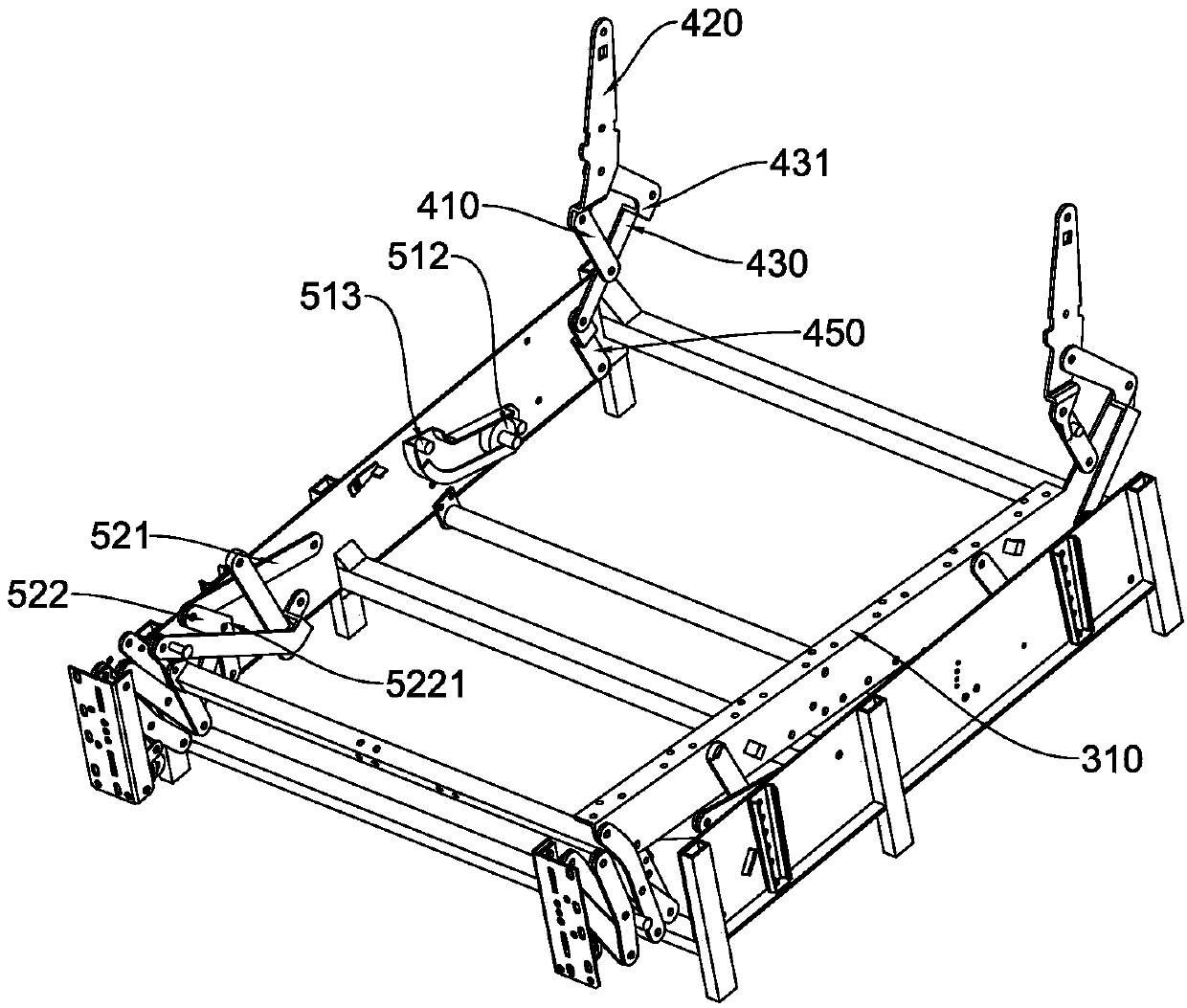

[0043] A backrest reclining mechanism of a seat functional frame, such as Figure 1-3 As shown, it includes a first backrest auxiliary assembly 510 and a second backrest auxiliary assembly 520 arranged symmetrically on the left and right sides of the fixed frame 100, and the first backrest auxiliary assembly 510 and the second backrest auxiliary assembly 520 are located on the fixed frame The rear part and the front part of 100; the first backrest auxiliary assembly 510 includes a slide rail 511 and a pulley 512 arranged in the slide rail 511 to facilitate the tilting and return of the backrest assembly 400, and the second backrest auxiliary assembly 520 includes a slide rail 512 that facilitates the backrest assembly 400 The auxiliary connecting piece A521 , the auxiliary connecting piece B522 and the auxiliary connecting piece C523 are hingedly connected to each other for reclining.

[0044] Among them, such as Figure 1-4 As shown, the slide rail 511 is fixedly arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com