Visual guide loading system suitable for vehicle top cover automatic carrying process

A vision-guided, car roof technology, used in transportation and packaging, program-controlled manipulators, chucks, etc., can solve problems such as low work efficiency, poor stability, and many failures, improve recognition accuracy and positioning accuracy, and reduce positioning requirements. , the effect of large detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

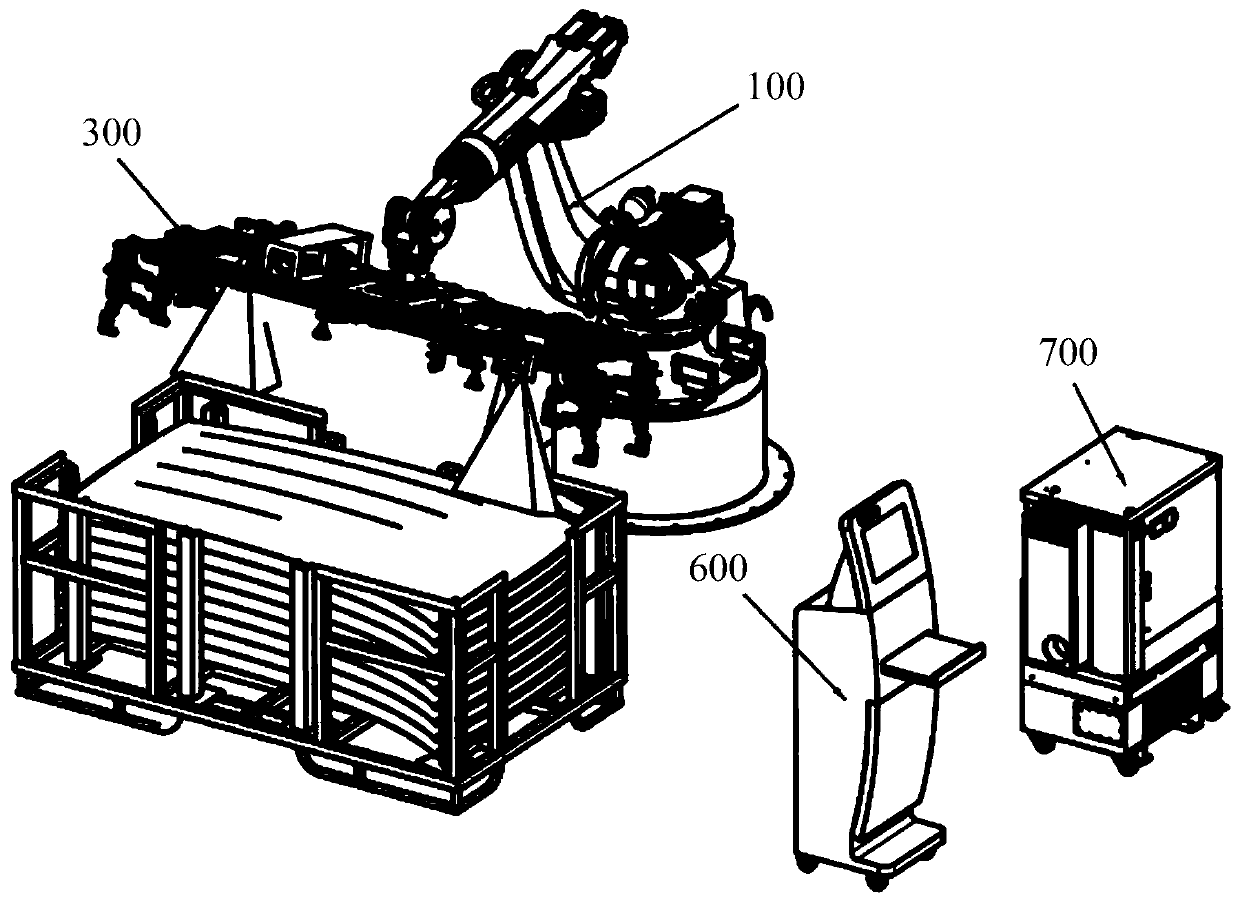

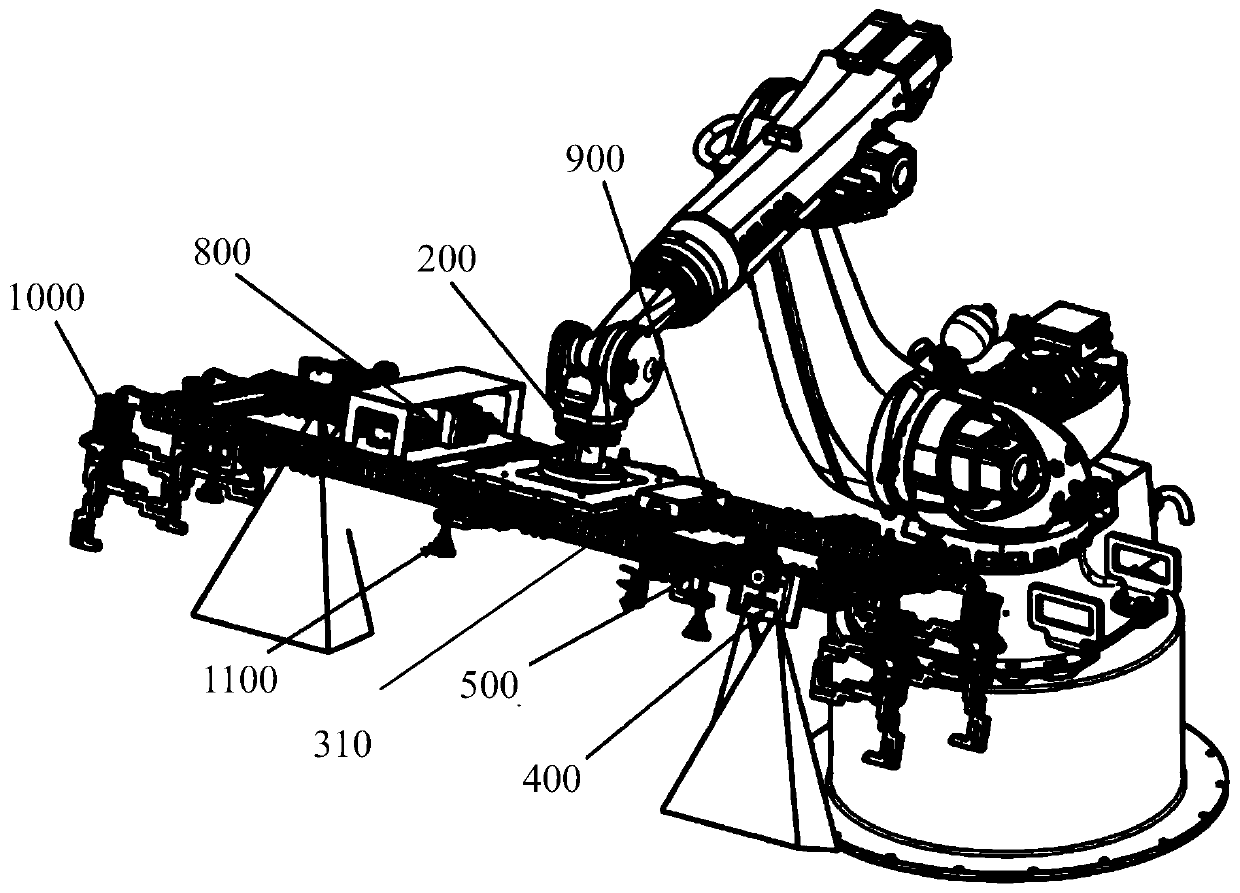

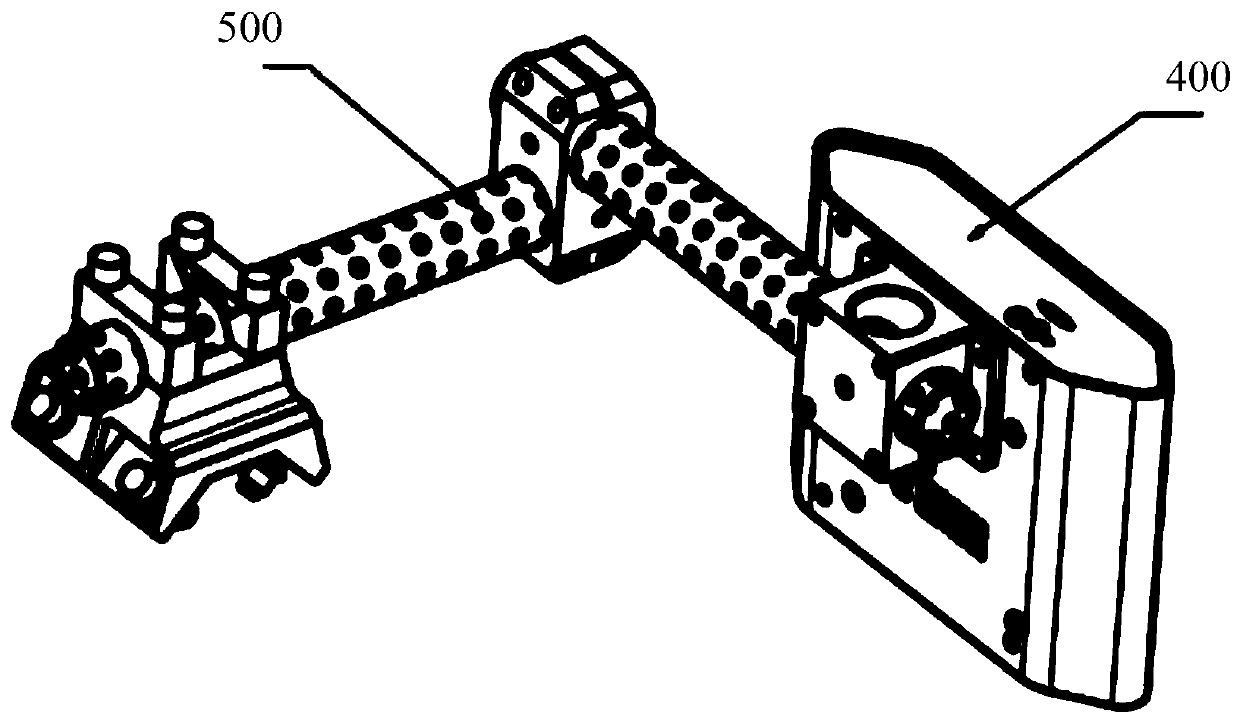

[0034] Such as figure 1 and figure 2 As shown, a vision-guided feeding system suitable for the automatic handling process of the roof cover of a car includes: a robot 100, a gripper heightening plate 200, a robot gripper 300, a visual three-dimensional scanner 400, a scanner connection mechanism 500, and an industrial control cabinet 600, robot control cabinet 700, valve island 800, vacuum generator 900, clamping cylinder 1000 and vacuum suction cup 1100, the robot gripper 300 is connected to the end of the robot 100 through the gripper heightening plate 200, and the visual three-dimensional scanner 400 is connected through the scanner The mechanism 500 is fixedly connected to the two diagonal positions of the robot gripper 300, the valve island 800 is connected to the upper part of the robot gripper 300 through the connecting plate, the industrial control cabinet 600 is connected to the external main power line, and the robot control cabinet 700 is internally connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com