Method for manufacturing hot-dip galvanized steel sheet

A technology of hot-dip galvanized steel sheet and manufacturing method, applied in hot-dip galvanizing process, manufacturing tools, heat treatment process control, etc. Effect of high adhesion and good plating appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

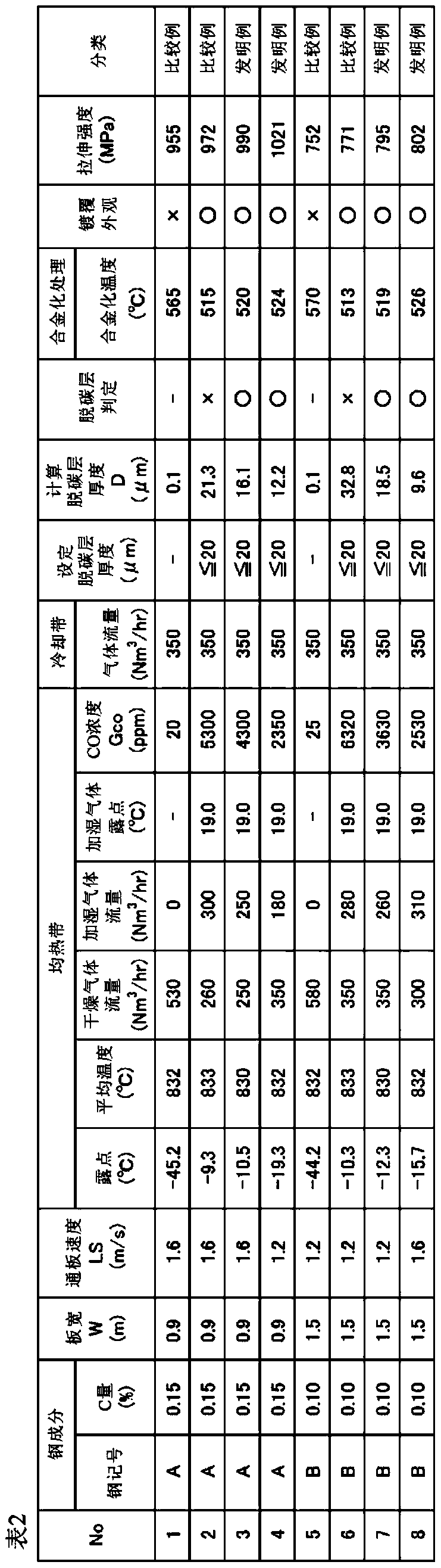

[0093] (experimental conditions)

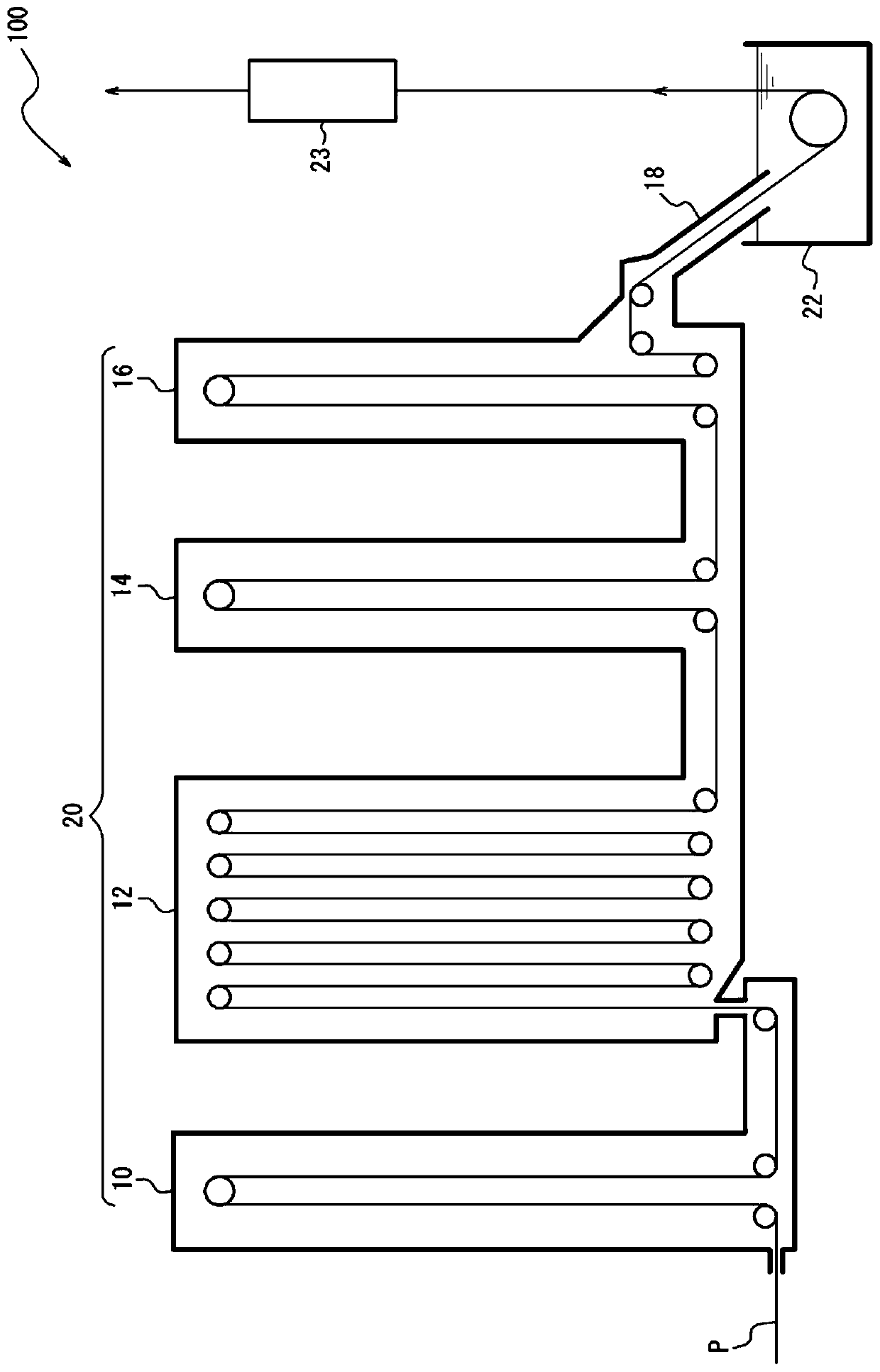

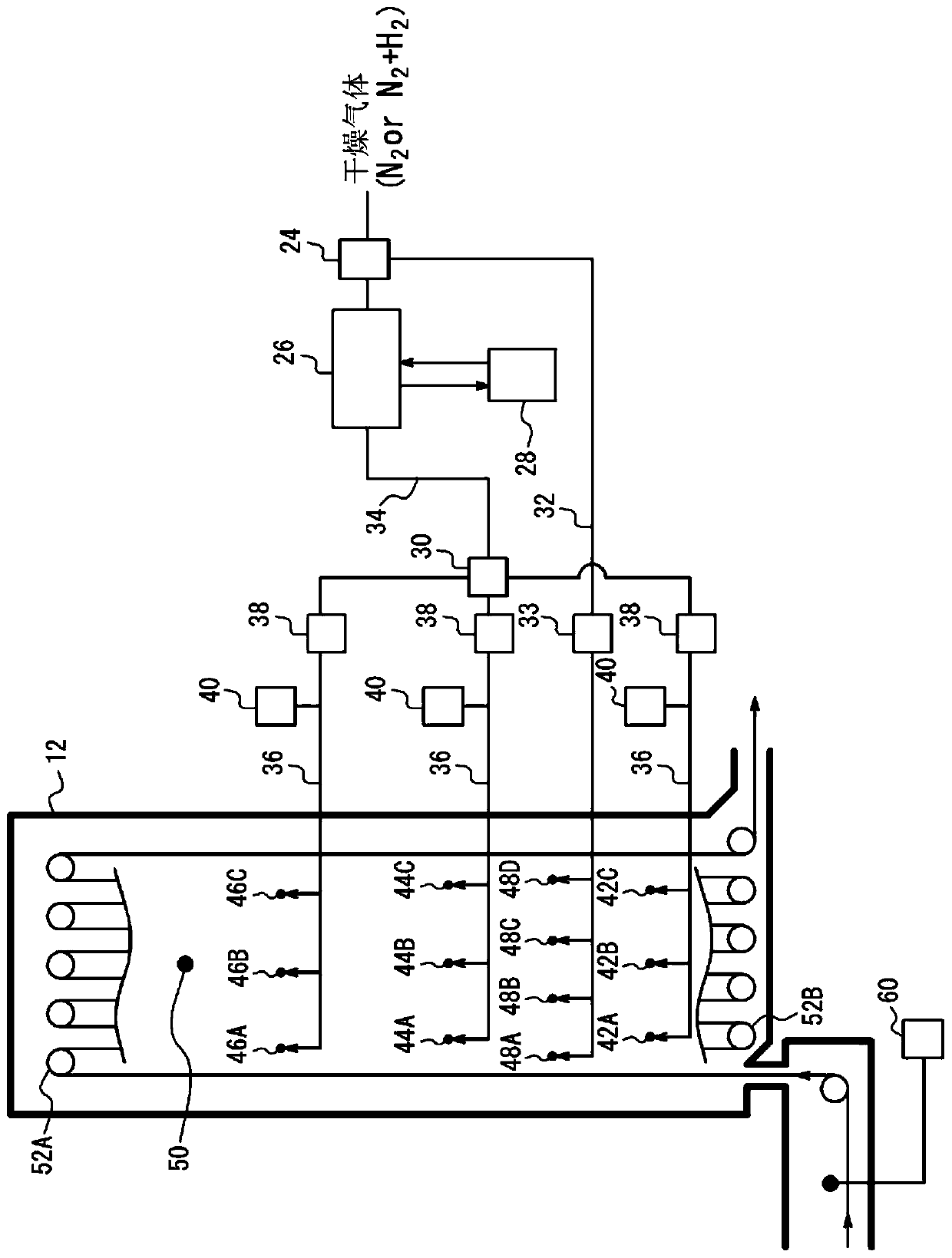

[0094] use figure 1 and figure 2 In the continuous hot-dip galvanizing apparatus shown, steel sheets with the composition shown in Table 1 (the rest is Fe and unavoidable impurities) were annealed under various annealing conditions shown in Table 2, and then hot-dip galvanized Zinc and alloying treatment.

[0095] The heating zone is a volume of 200m 3 RT furnace. The average temperature inside the heating zone is 700 to 800°C. In the heating zone, as a dry gas, a H with 15% by volume is used 2 and the remainder consists of N 2 Composition of gas (dew point: -50°C) and unavoidable impurities. The flow rate of drying gas to the heating zone is 100Nm 3 / hr.

[0096] The average tropical zone has a volume of 700m 3 RT furnace. The average temperature inside the soaking zone was set to the temperature shown in Table 2. As a dry gas, use H with 10 vol% 2 and the remainder consists of N 2 Composition of gas (dew point: -50°C) and una...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com