Manufacturing method of hot-dip galvanized steel sheet

A technology of hot-dip galvanized steel sheet and manufacturing method, which is applied in the direction of hot-dip galvanizing process, manufacturing tools, heat treatment process control, etc., can solve the problems of reduced wettability, poor plating adhesion, missing plating, etc., and achieve good plating Effect of high plating appearance and plating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

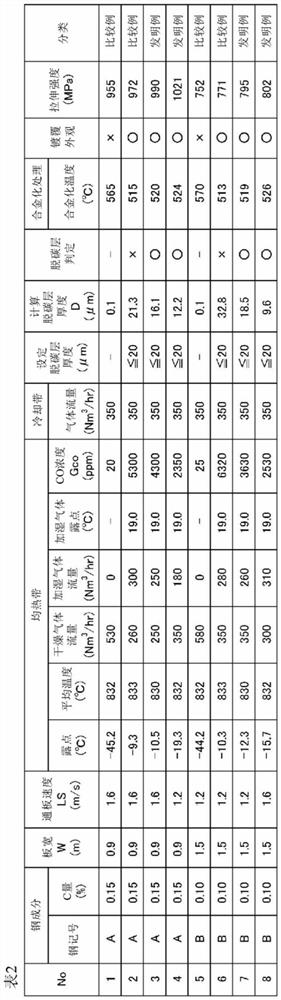

[0093] (Experimental condition)

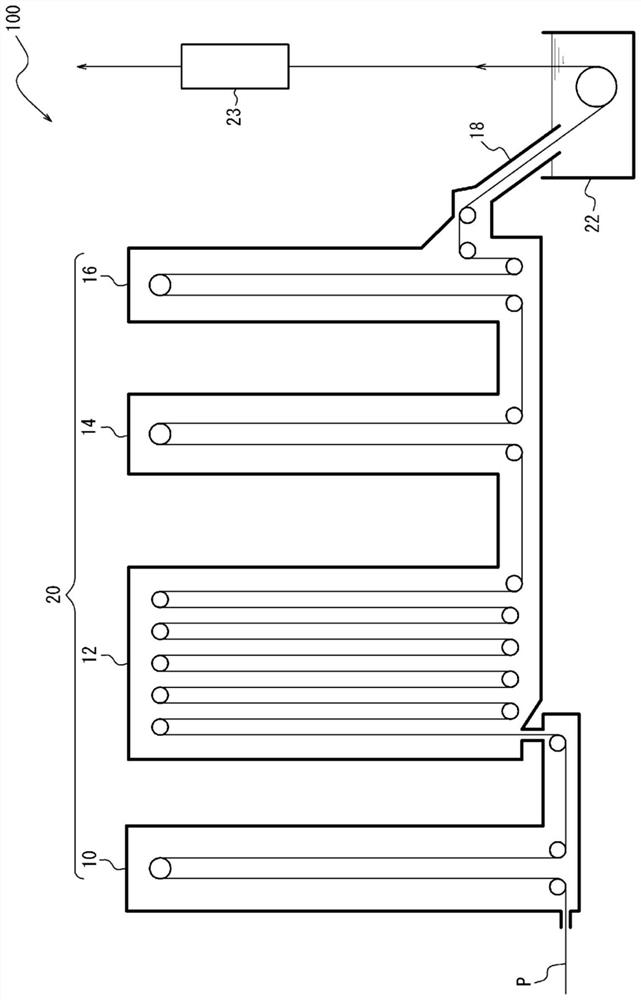

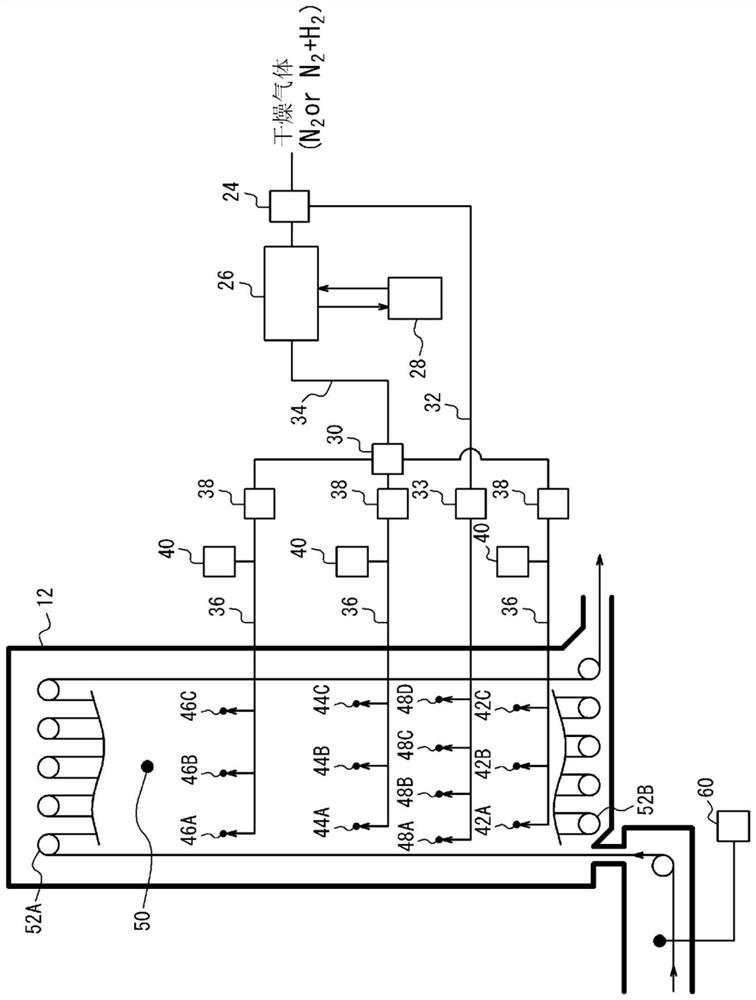

[0094] use figure 1 with figure 2 Continuous hot dip galvanizing apparatus shown in the composition components shown in Table 1 (remainder being Fe and inevitable impurities) of the steel sheet shown in Table 2 was annealed at various annealing conditions, followed by hot dip plating zinc and alloying treatment.

[0095] Plus the tropics is a volume of 200m 3 The RT furnace. The average temperature inside the heating zone of 700 ~ 800 ℃. In the heating zone, as the drying gas, having a 15% by volume of H 2 And the balance N 2 Gas composition and unavoidable impurities (dew point: -50 ℃). The flow rate of the drying gas heating zone is 100Nm 3 / Hr.

[0096] Soaking zone is a volume of 700m 3 The RT furnace. The average temperature inside the soaking zone is set to a temperature shown in Table 2. As a drying gas, having a 10% by volume of H 2 And the balance N 2 Gas composition and unavoidable impurities (dew point: -50 ℃). The use of a portion of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com