serpentine guide jet

A injector and serpentine technology, applied in the field of serpentine-guided injectors, can solve the problems that affect the workover efficiency, the wellbore or trunk pipeline cannot be unblocked, and achieve the effect of improving the success rate and force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

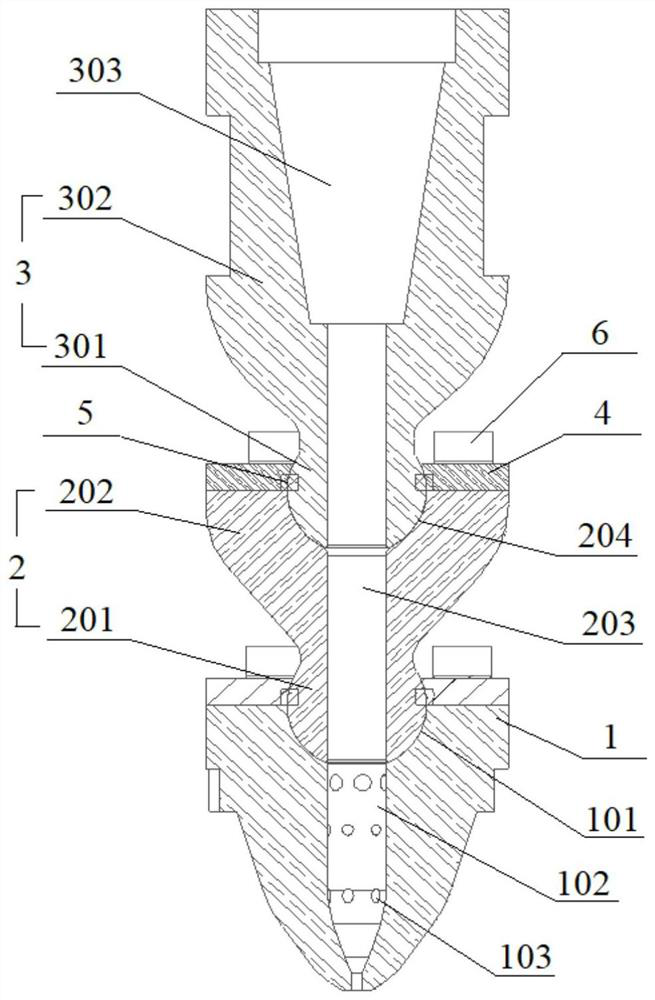

[0031] Before further detailed description of the embodiments of the present invention, the orientation nouns involved in the embodiments of the present invention, such as "upper end", "upper", "lower", "upper", "lower", are figure 1 The orientation shown in the figure is used as a reference, and is only used to clearly describe the structure of the serpentine guide injector according to the embodiment of the present invention, and does not have the meaning of limiting the protection scope of the present invention.

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0033] An embodiment of the present invention provides a serpentine guide injector, which includes: a nozzle 1 and at least one movable joint 2 .

[0034] Wherein, each movable joint 2 includes a connected first part 201 and a se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap