Condensate cylinder blockage removing device and blockage removing method

A technology of condensing liquid and removing plugging, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, and dust removal, etc. It can solve problems such as coal seam well production loss, coal seam reservoir damage, and high difficulty in construction operations, so as to reduce costs and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

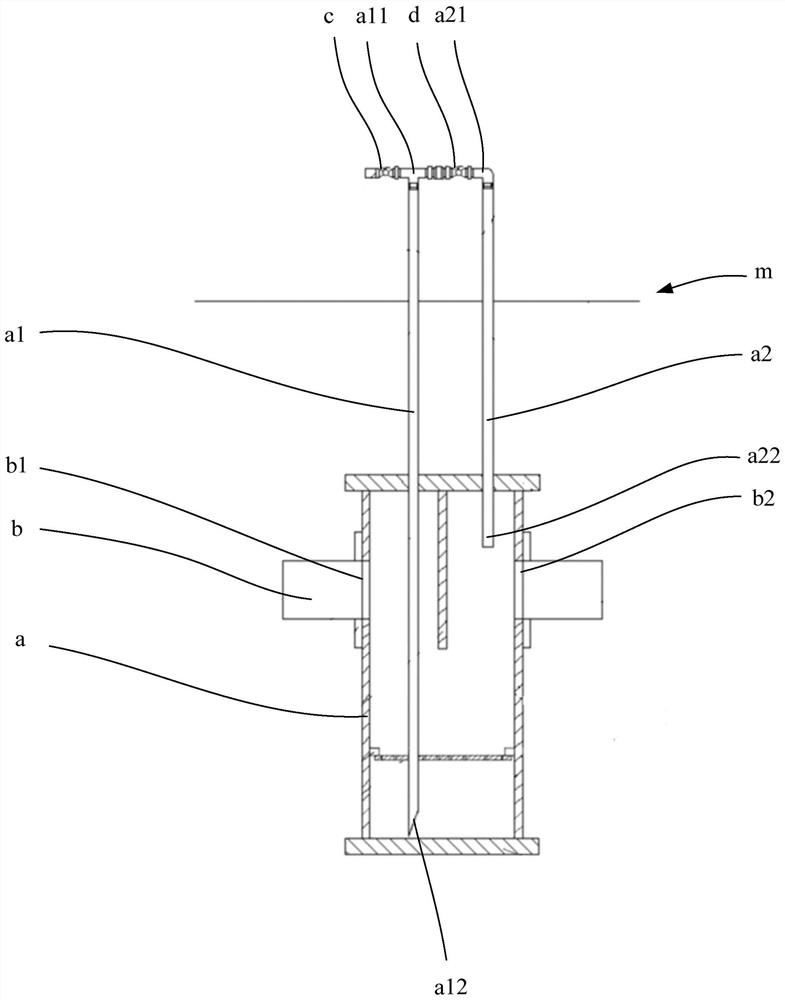

[0047] figure 1 It is a structural schematic diagram of a liquid condensation cylinder in the related art. Such as figure 1 As shown, in the related art, the condensate cylinder a is usually buried at a depth of 2-2.5m underground, and the opposite side walls of the condensate cylinder a have air inlets b1 and Air outlet b2. The distance between the bottom of the condensate tank a and the ground m is greater than the distance m between the air inlet b1 and the gas outlet b2 from the ground, so that the coalbed methane accumulation in the gas pipeline b enters the condensate tank a and then gathers in the condensate tank a bottom of the cylinder. The condensate cylinder has a discharge pipe a1 and a balance pipe a2 connected to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap