Blade type waterproof connector

A technology of waterproof connectors and switch blades, which is applied in the direction of connections, parts of connection devices, coupling devices, etc., which can solve the problems of elastic fatigue, reduce the waterproof effect of connectors, and have very high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

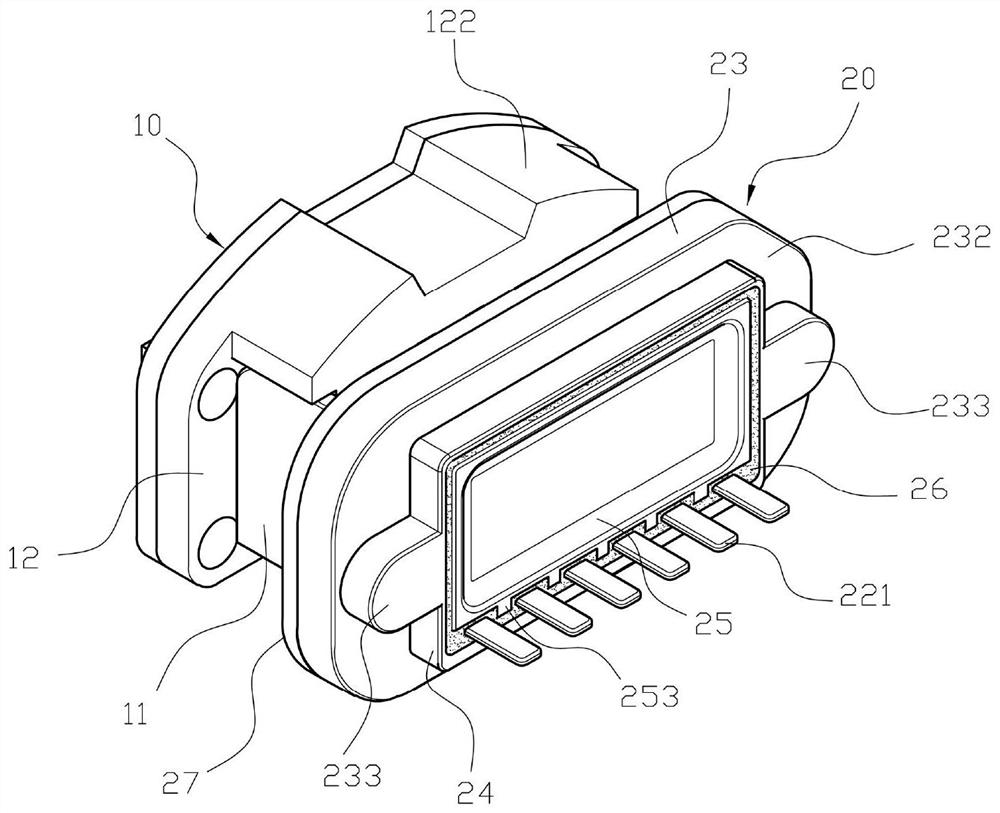

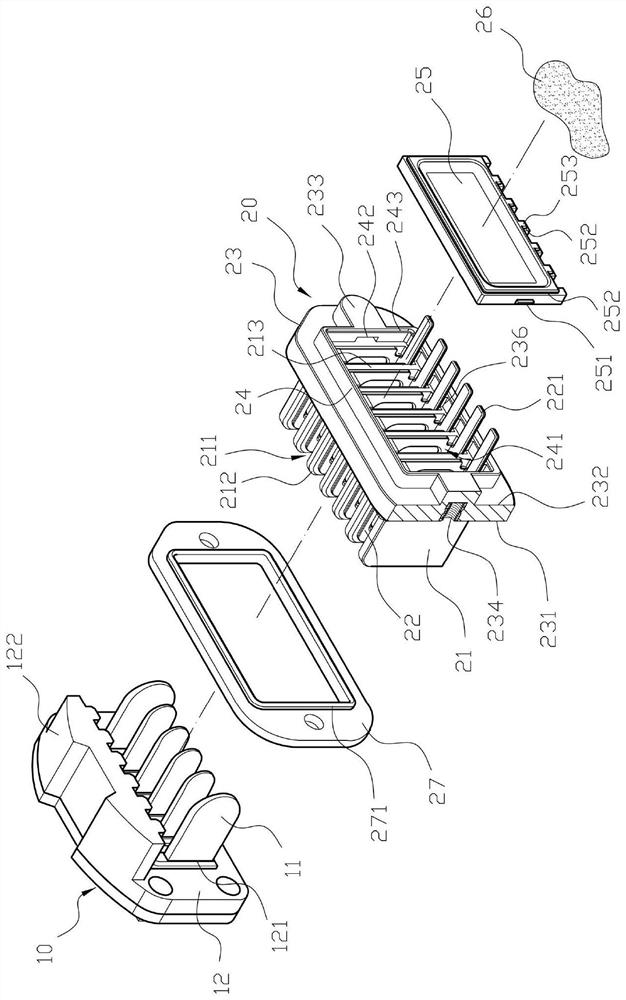

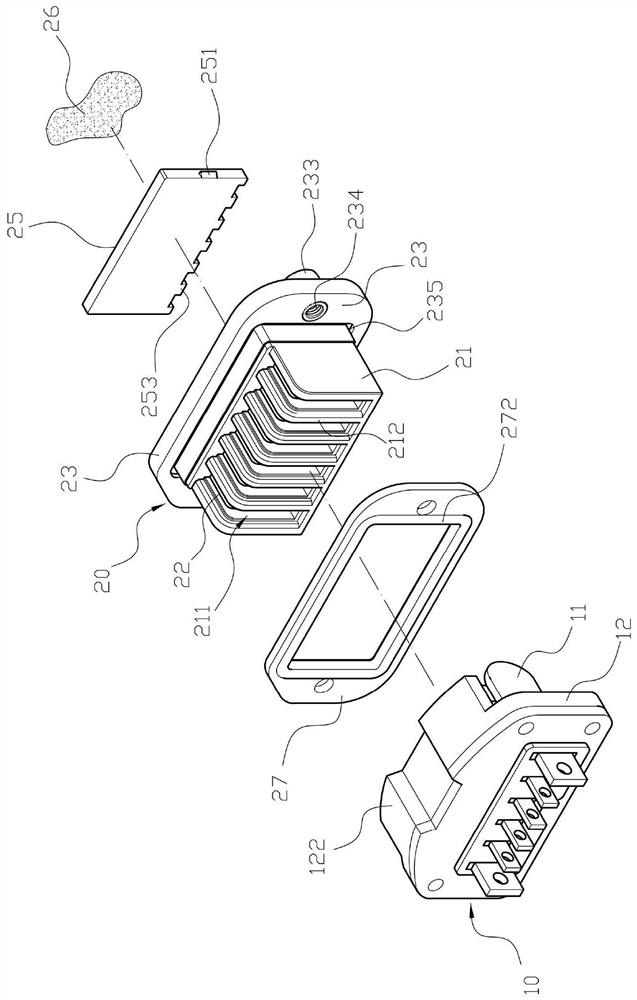

[0069] first please figure 1 Continuous to Figure 4 As shown, a knife-type waterproof connector includes: a first connector 10 and a second connector 20, a first connector 10 is provided with a plurality of first terminals 11, the first The connector 10 is combined with a seal 12, and the seal 12 is provided with a plurality of perforations 121, and the perforations 121 provide the penetration of the first terminal 11, and the seal 12 is right-angled, and the seal 12 A side block 122 is formed, and a second connecting member 20 forms a connecting seat 21 at one end, and the connecting seat 21 is in a right-angle shape, and the connecting seat 21 is provided with a plurality of L-shaped grooves 211, and each of the L-shaped grooves 211 A second terminal 22 is fixed inside, so that the first terminal 11 and the second terminal 22 are interconnected to form electrical conduction between the first connector 10 and the second connector 20, and the first terminal 11 When intercon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com