Axial multi-stage pressure reduction sleeve and multi-stage pressure reduction valve containing same

A pressure-reducing valve and sleeve technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of bulky valves, increased valve cavity volume, and increased risk of valve clogging, achieving compact structure, improved adjustment accuracy, Significant effect of blood pressure reduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

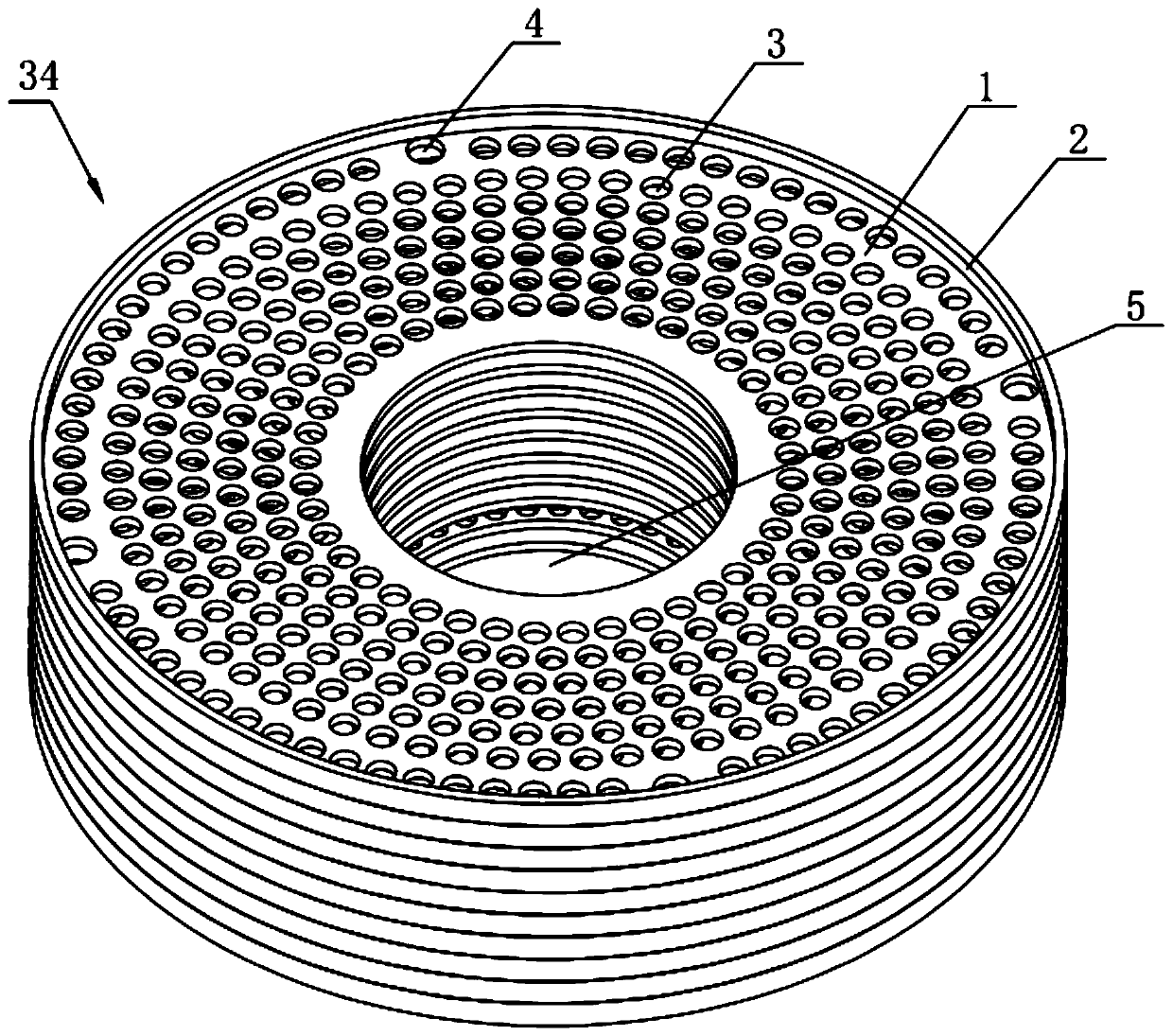

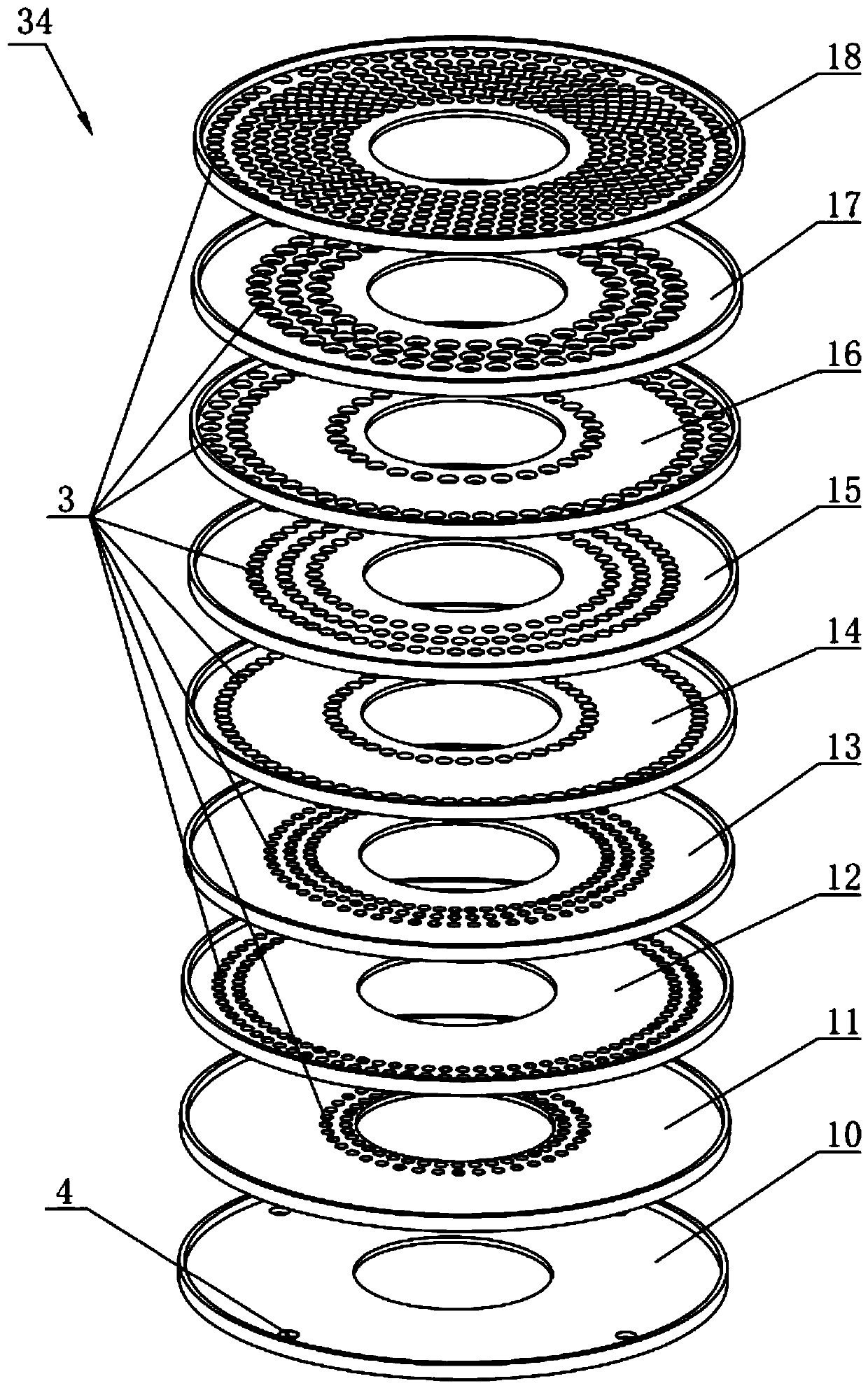

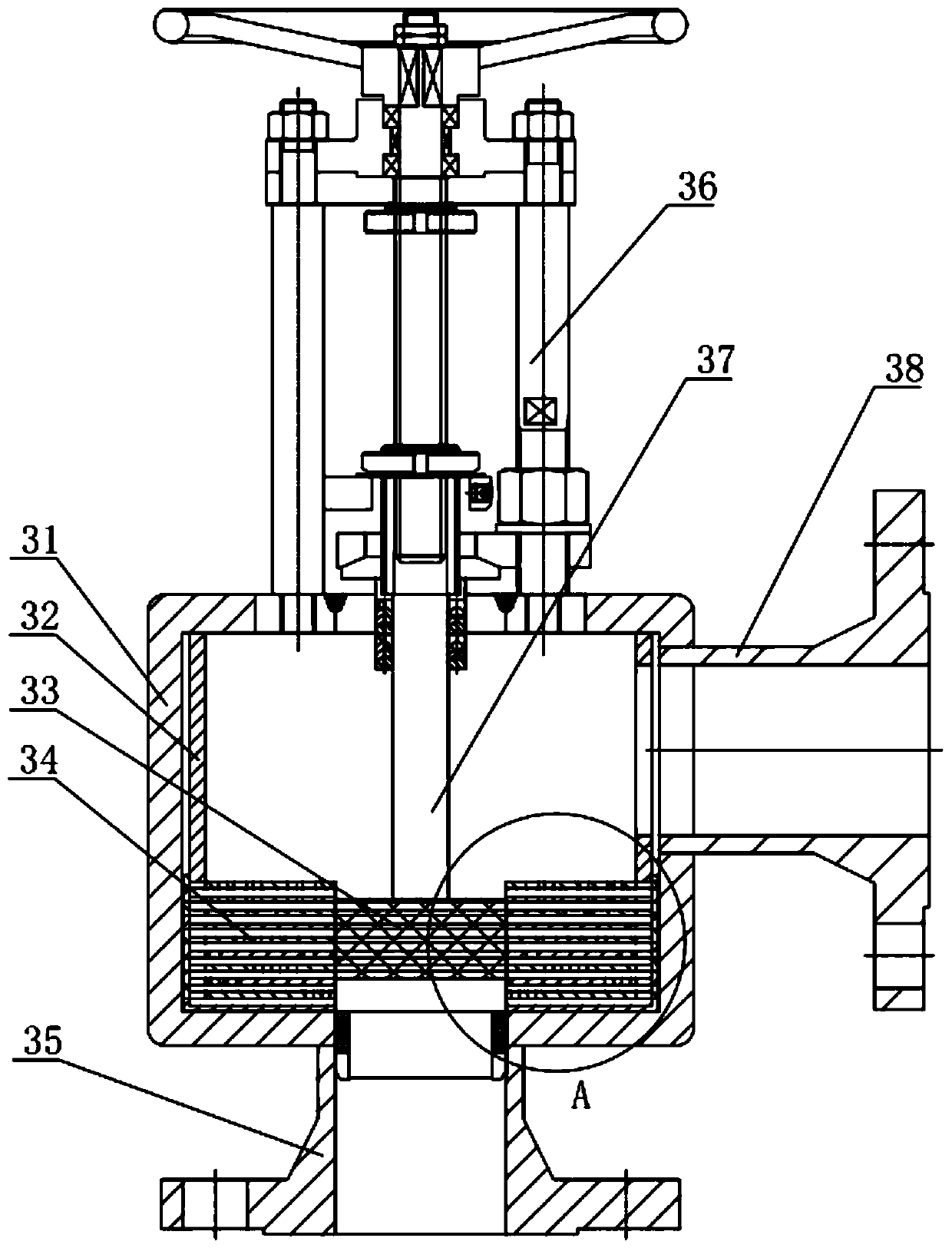

[0031] Such as figure 1 with figure 2 As shown, the axial multi-stage pressure-reducing sleeve of this embodiment includes multi-layer disks 1 spaced along the axial direction, and the space between adjacent disks 1 forms an interlayer flow channel; A plurality of through holes 3 are opened, and the plurality of through holes 3 are evenly distributed on the disc 1 with the center of the disc 1 as the center; the through holes 3 on adjacent discs 1 are distributed in a staggered manner along the radial direction of the disc 1 so that the fluid flows in the The circuitous flow in each interlayer channel.

[0032] Through the multi-layer disk 1 structure stacked axially, and through holes 3 are staggered on the adjacent disk 1 along its radial direction, the fluid flows in a circuitous way in each interlayer flow channel of the sleeve, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com