An imaging-based macro measuring device, method and equipment

A measurement method and measurement device technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve problems such as failure to meet measurement requirements, complex operations and algorithms, and damage to measurement objects, so as to improve recognition ability and high test accuracy , the effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

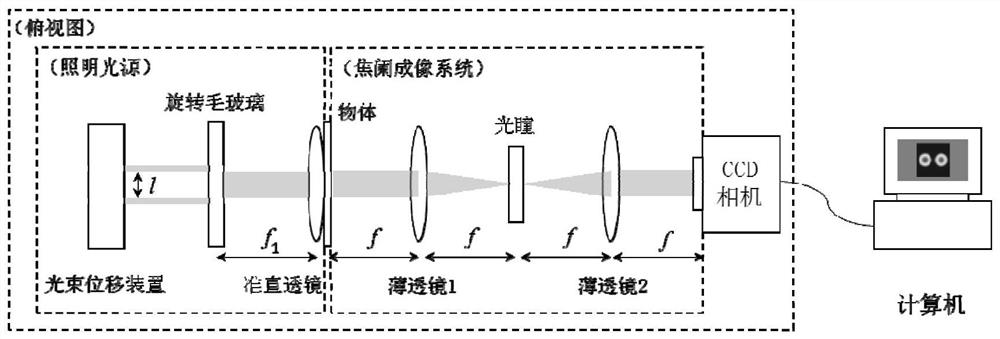

[0046] Such as figure 1 As shown, Embodiment 1 of the present disclosure provides an imaging-based macro-distance measurement device, which mainly includes an illumination source, an object to be measured, an imaging system, and a CCD camera connected to a computer.

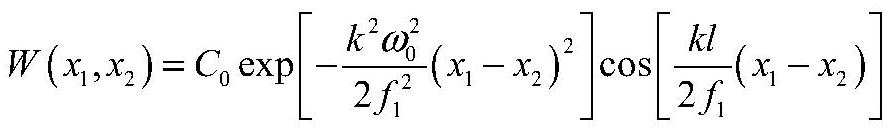

[0047] Among them: the illumination source is constructed by two fiber laser sources, a beam displacement device (which can precisely control the distance between two fibers), rotating frosted glass and a collimating lens;

[0048] The imaging system is a 4f imaging system composed of two identical thin lenses, and a pupil is placed on its spectrum plane. This imaging system is also called a telecentric imaging system;

[0049] In addition, the CCD camera records the measured light intensity values in grayscale values, and the grayscale values can be read and processed by the commercial software matlab. In order to make the analysis simple and clear, we only consider the horizontal direction.

[0050] (1) L...

Embodiment 2

[0095] Embodiment 2 of the present disclosure provides a macro-distance measurement device, including the imaging-based macro-distance measurement device described in Embodiment 1 of the present disclosure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com