Y-directional drive embroidery frame structure with front and rear double auxiliary rails

An embroidery frame and front frame technology, applied in the field of embroidery machine driving equipment, can solve the problems of frame jitter and less number of Y-direction drives, and achieve the effects of reducing needle breakage rate, improving stability and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below according to the drawings and embodiments.

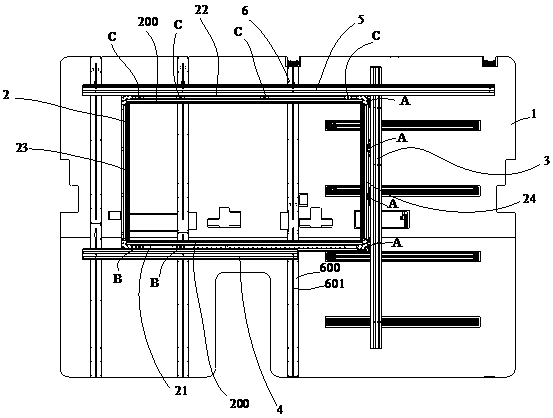

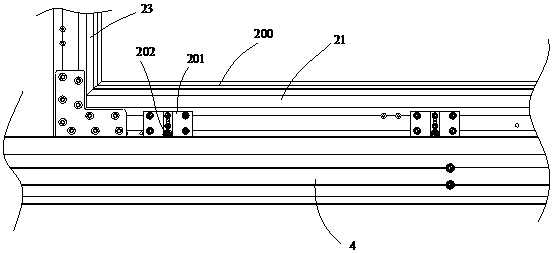

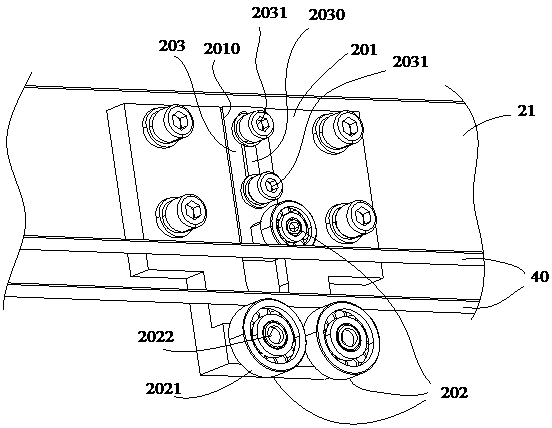

[0038] refer to Figure 1-11 , the present invention, Y to drive the embroidery frame structure with front and rear double auxiliary rails, which includes a platen 1, a frame 2, an X auxiliary rail 3, a Y front auxiliary rail 4, a Y rear auxiliary rail 5, and two connecting plates Component6. Wherein, the frame 2 is arranged on the platen 1, and the frame 2 includes a front frame 21, a rear frame 22, a left frame 23, and a right frame 24. The four frames form a rectangular structure, and the function of the frame 2 is to fix cloth rack, and in order to facilitate the replacement of the cloth rack by the user, the structural setting of the frame 2 can be set to be easy to disassemble. Usually, the front frame 21 and the rear frame 22 are wide sides, so one of the front frame 21 and the rear frame 22 is set to a detachable structure, or the front frame 21 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com