Heat destructive disconnecting switch and socket with such switch

A technology of thermal destruction and switching, which is applied to the components of flip switches/rocker switches, electric switches, thermal switches, etc., which can solve the problems of incomplete socket contact, incomplete insertion, and price rise, and achieve price improvement. Expensive, simple overall structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

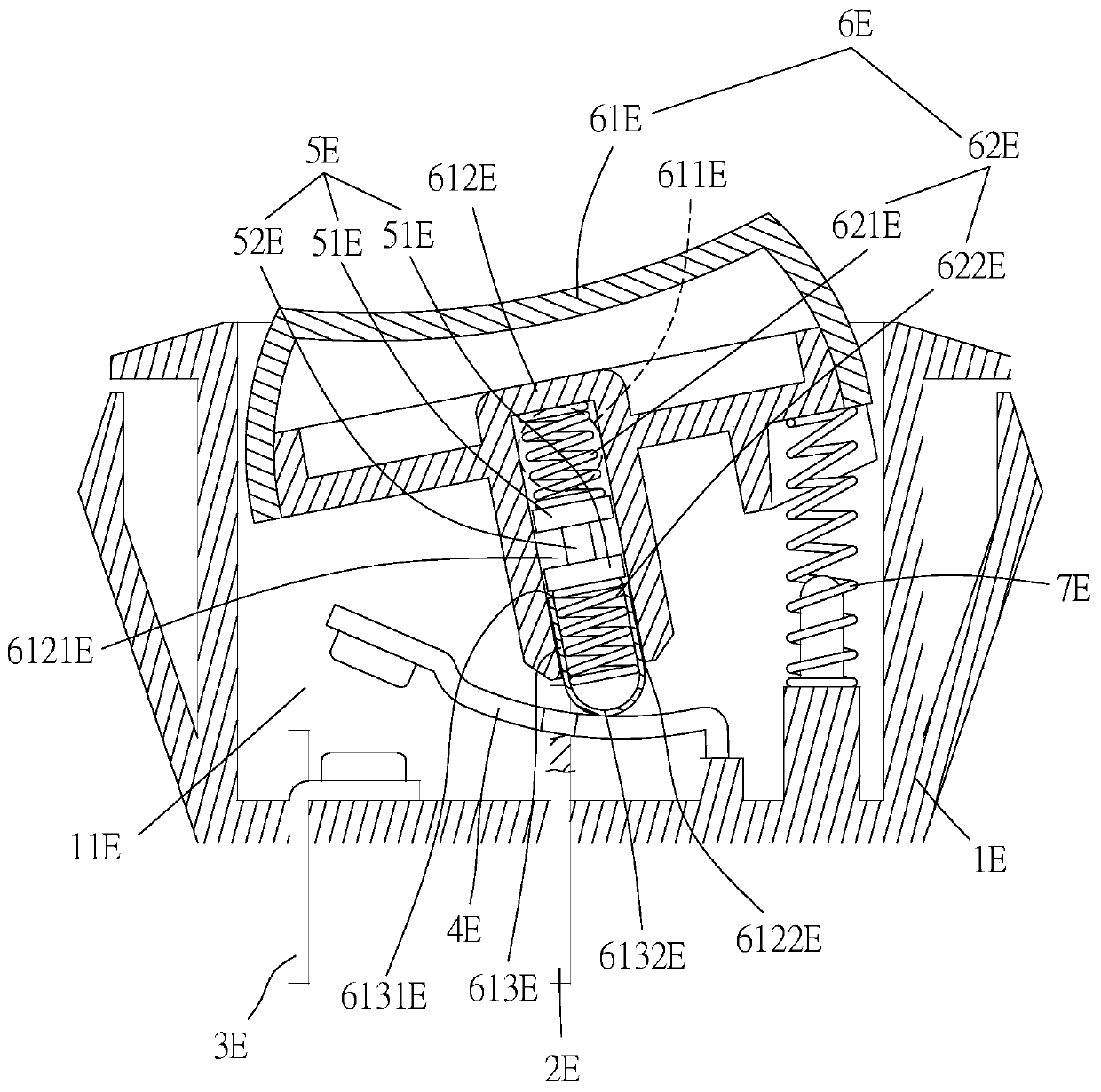

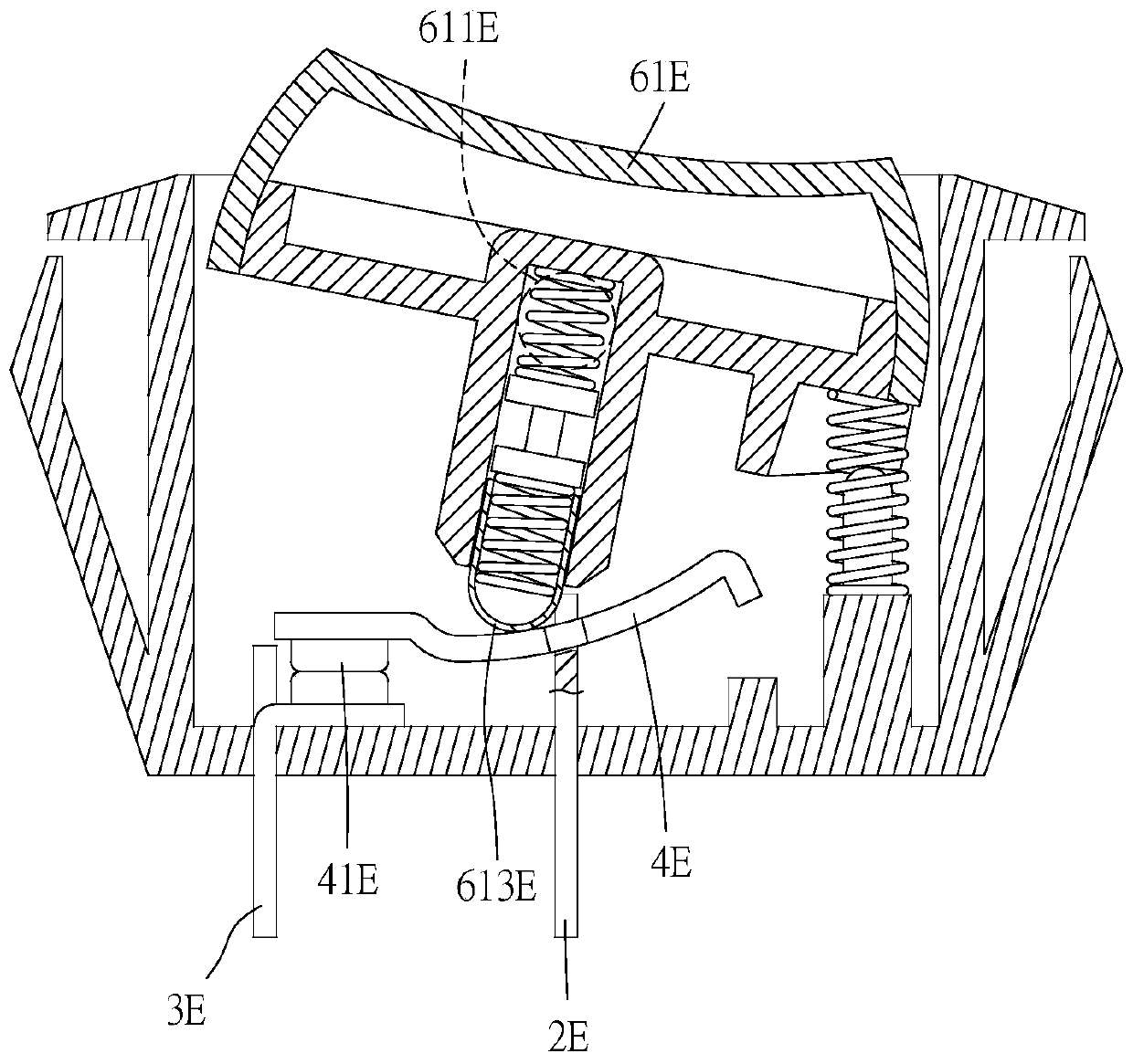

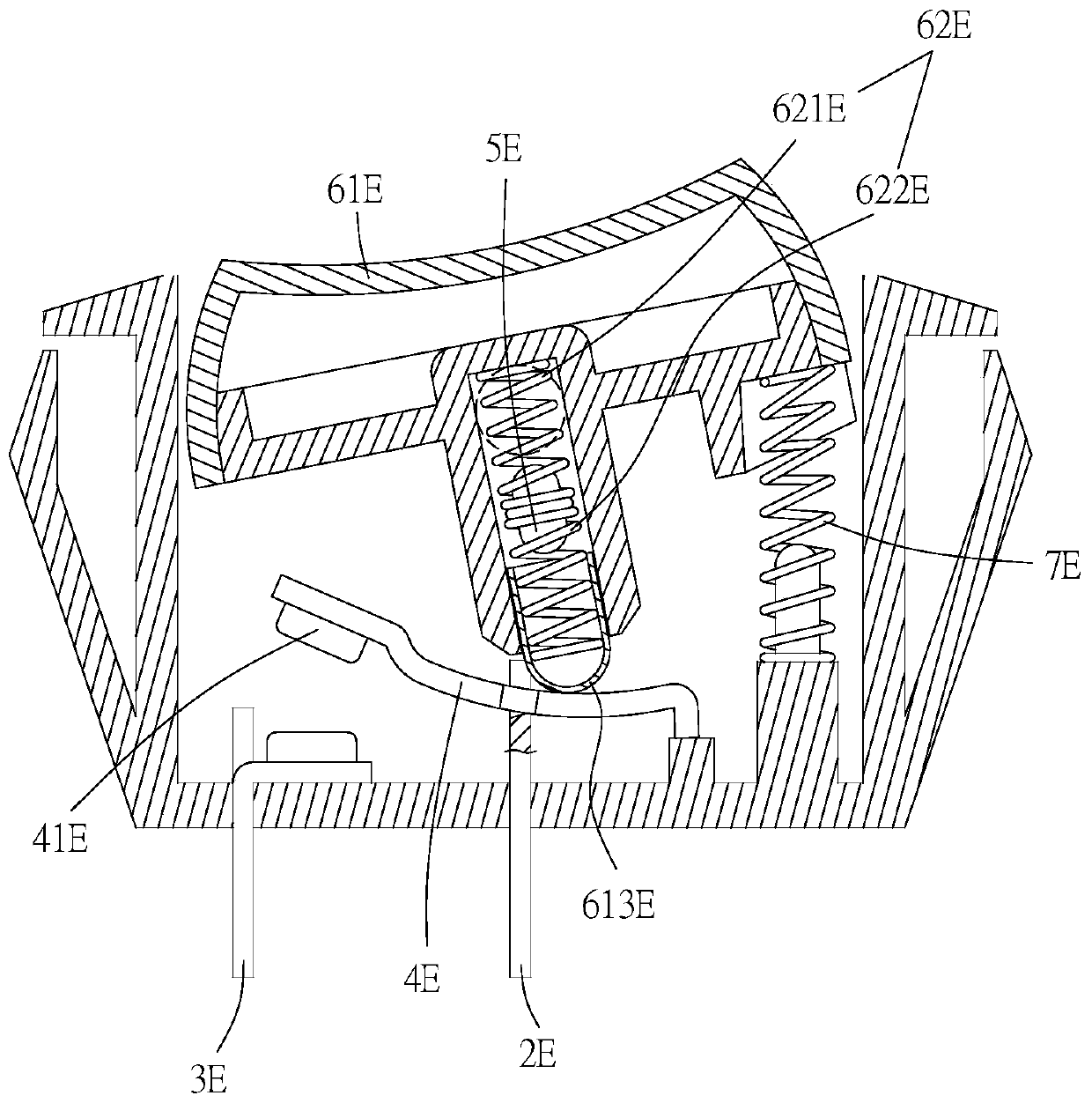

[0048] Based on the above technical features, the main functions of the socket of the present invention and its heat-damaged power-off switch can be clearly presented in the following embodiments.

[0049] Please refer to the first embodiment of the present invention figure 1 As shown, this embodiment is a switch for thermal damage and power-off, and in this embodiment it is a rocker switch, and figure 1 Indicates that the rocker switch is off.

[0050] The rocker switch includes:

[0051] The seat 1E has an accommodating space 11E. A first conductive element 2E and a second conductive element 3E are both passed through the base body 1E. A movable conductive part is arranged in the accommodating space 11E, the movable conductive part is a seesaw conductive part 4E, the seesaw conductive part 4E straddles the first conductive part 2E and is electrically connected to the first conductive part 2E . An overheating damage member 5E can be destroyed at a damage temperature rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com