Lifting type tribed

A lifting and end-frame technology, applied in the field of three-layer beds, can solve the problems of wasting valuable space and occupying a lot of space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

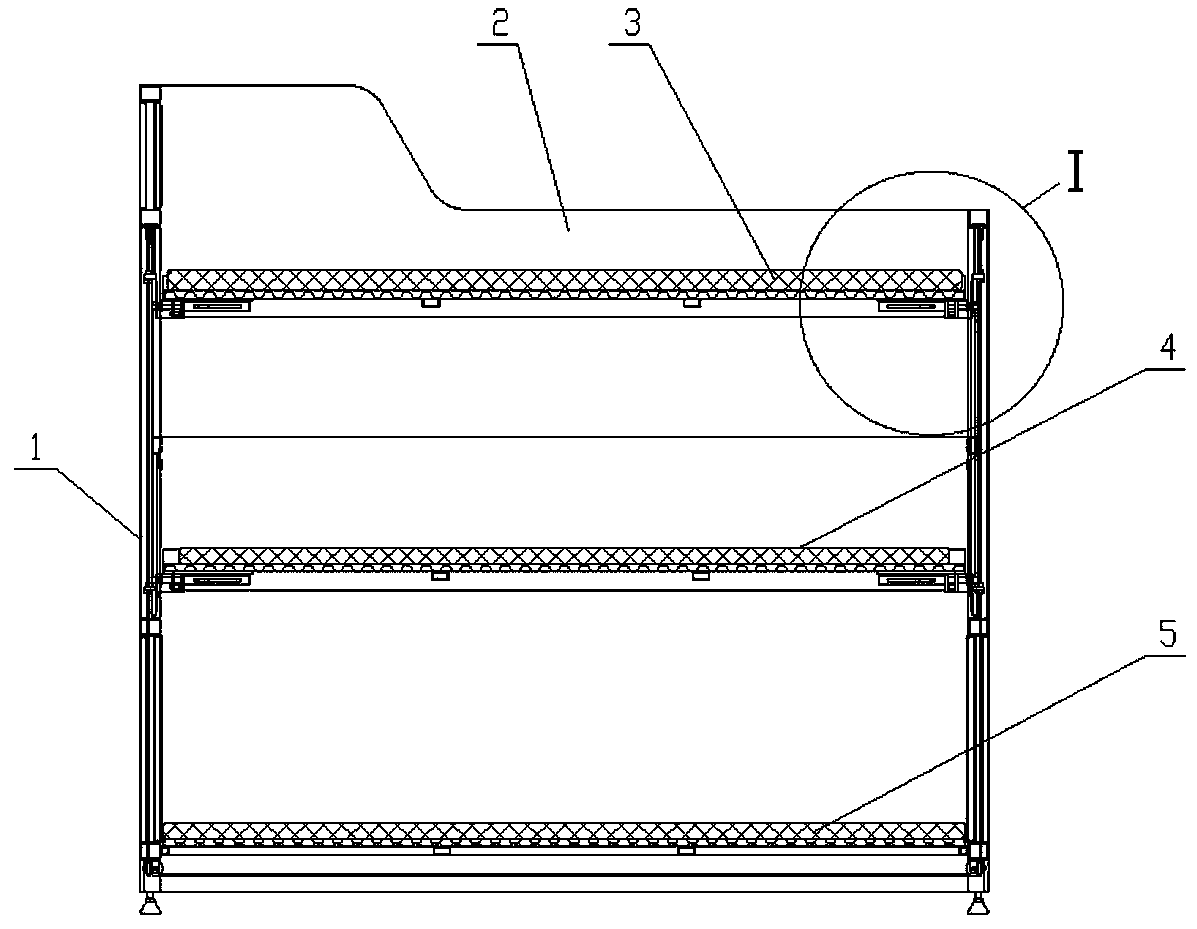

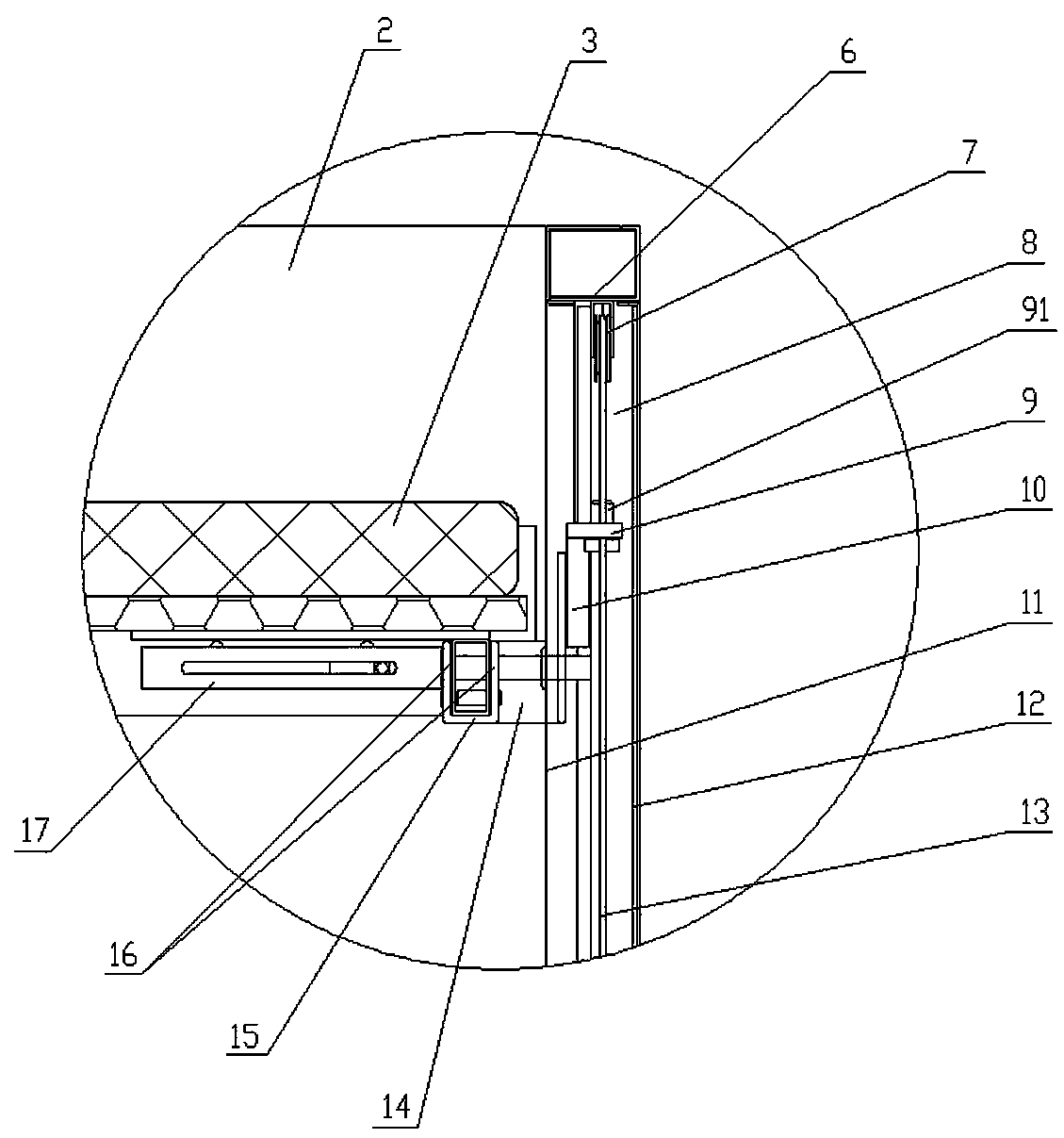

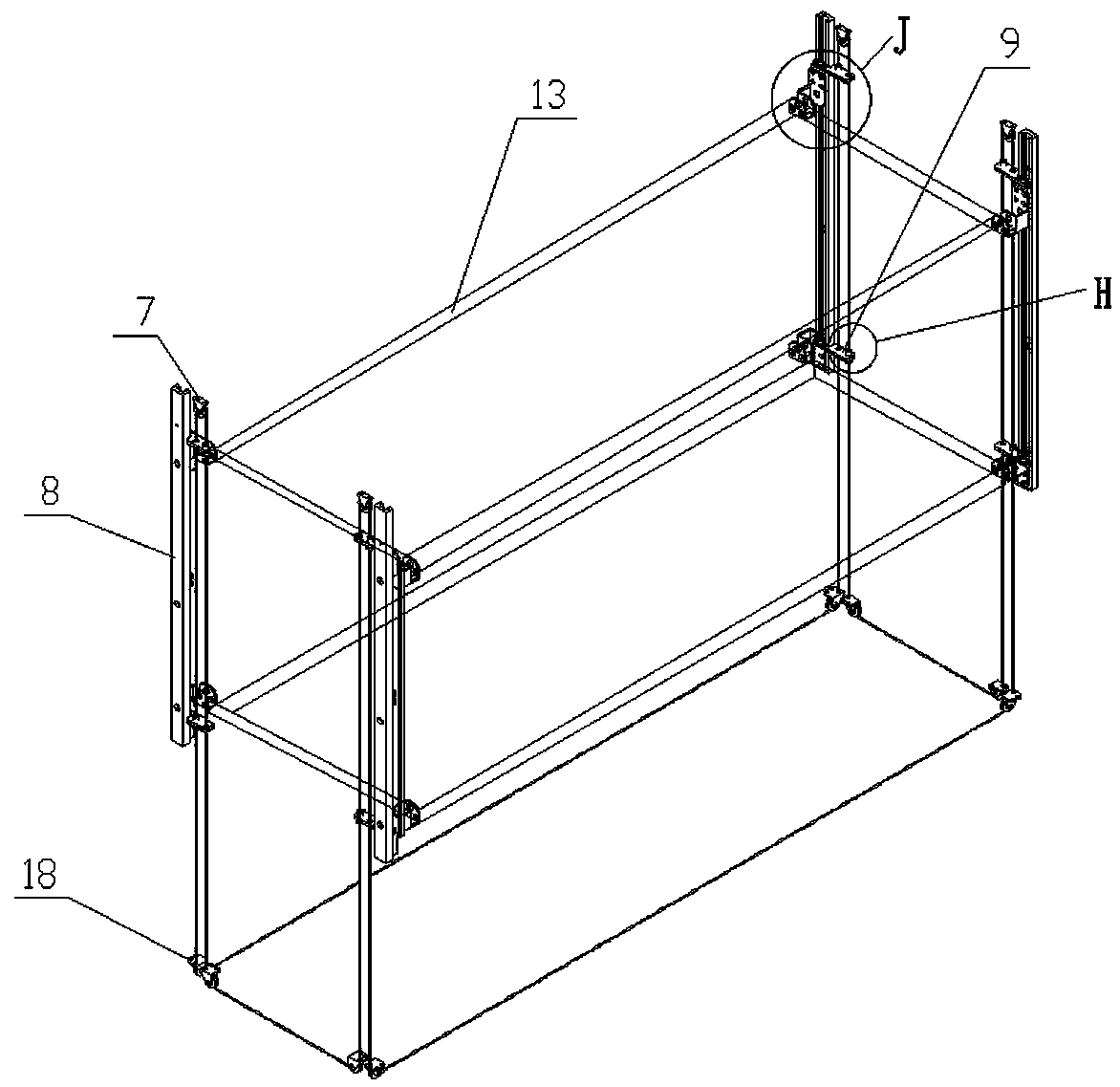

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the lifting type three-layer bed of the present invention contains two end frames 1, and a backboard 2 is connected between the vertical sides of the same side of the two end frames 1, and the vertical distance between the end frames 1 and the backboard 2 is from bottom to top. A lower berth 5, a middle berth 4 and an upper berth 3 are arranged successively, and the four corners of the lower berth 5 wherein are fixedly connected with the inner sides of the lower sides of the two end frames 1.

[0016] The end frame 1 is a hollow plate structure, and vertical guide rails 8 are fixed in its two vertical sides, and the length of the vertical guide rails 8 is greater than the distance between the upper bunk 3 and the middle bunk 4 . Top plate 6 inboard two ends of end frame 1 are all fixed with upper wheel base, and upper pulley 7 is all installed on the upper wheel base. The base plate inboard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com