Concrete material self-repairing capsule manufacturing device and concrete material self-repairing capsule manufacturing method

A self-healing and concrete technology, which is applied to the production device and field of self-healing capsules of concrete materials, can solve the problems of time-consuming, low efficiency, and complicated microcapsule steps, and achieve good economic and social benefits, recovery strength and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in more detail below in conjunction with the accompanying drawings.

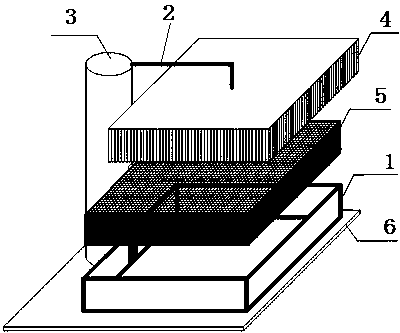

[0033] A concrete material self-repairing capsule manufacturing device, characterized in that it includes a cutting device, a lifting device, a base, a metal box, a sodium silicate mold, and an epoxy resin sheet mold, the lifting device is connected with the cutting device, and the metal box is set on the base. The cutting device is set in the metal box;

[0034] Sodium silicate mold and epoxy resin sheet mold are independent parts.

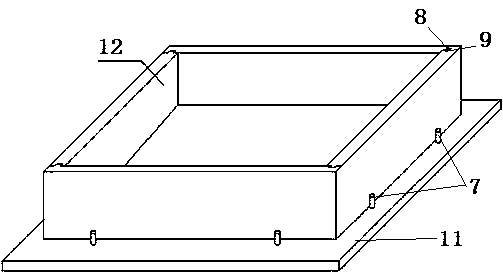

[0035] figure 2 As shown, the epoxy resin sheet mold is composed of a lower plate 11 and four vertical plates 10, and the four vertical plates 10 are connected end to end in turn to form a closed quadrilateral frame. Post 7, the limit post 7 positions the quadrangular frame.

[0036] image 3 , Figure 4 As shown, the sodium silicate mold is composed of several cylinders 14, circular slices 15, crossbars 16, and long rods 17....

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com