Continuous cutting device for copper-clad plate processing

A copper clad laminate and cutting technology, which is applied in the field of continuous cutting devices, can solve the problems of copper clad laminate cutting size change, copper clad laminate offset, etc., and achieve the effect of increasing the firmness of installation and avoiding breakage and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

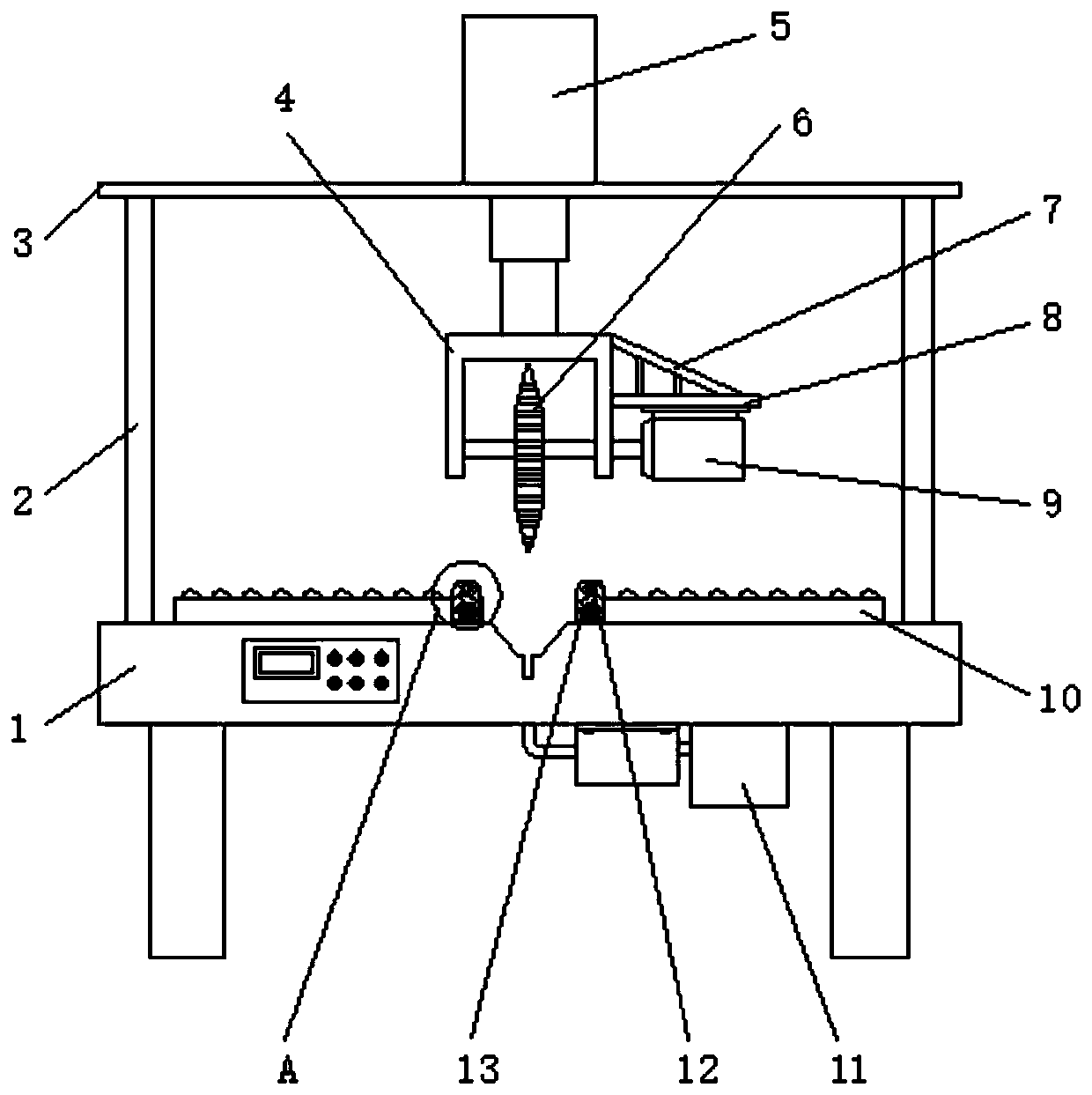

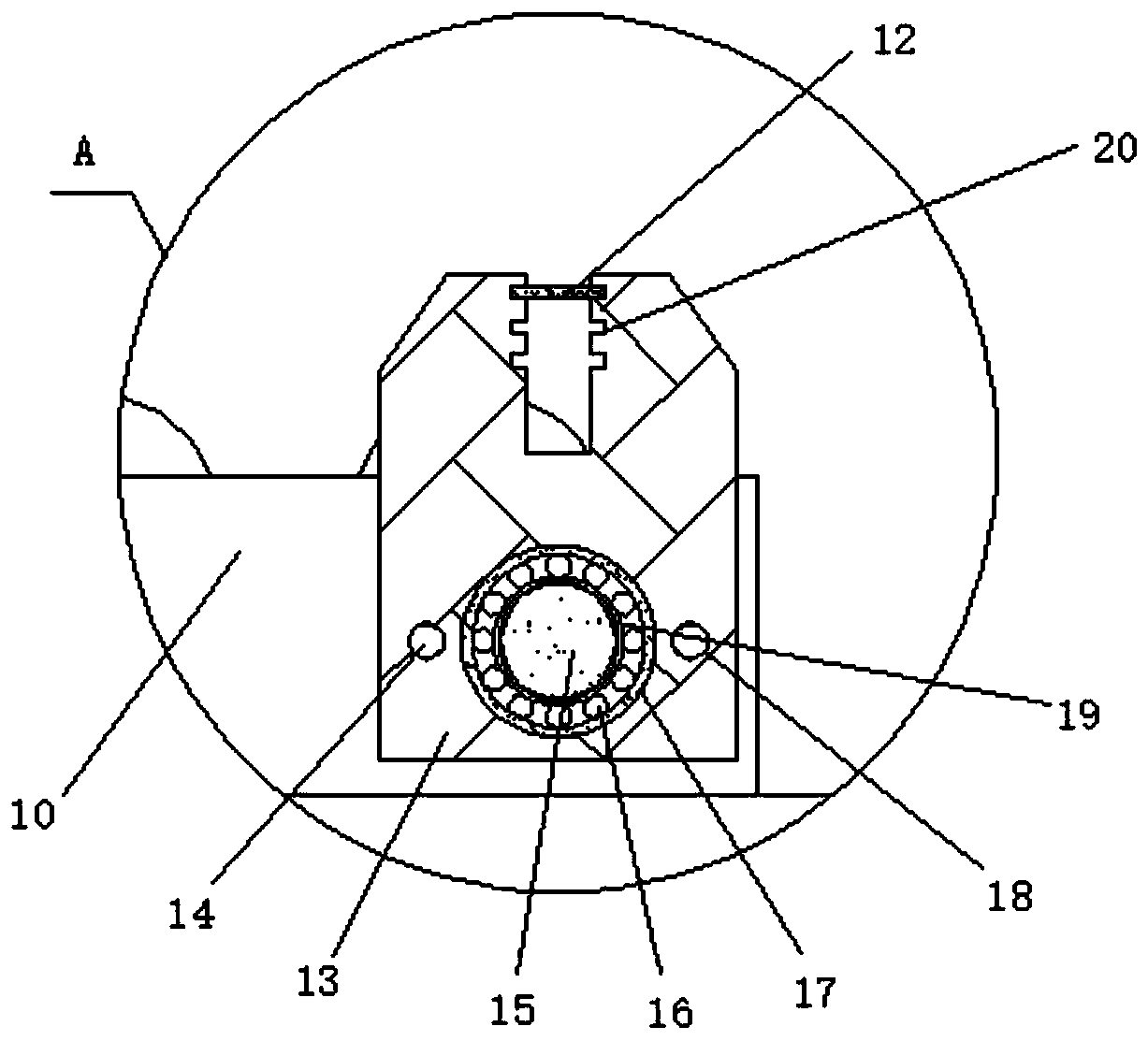

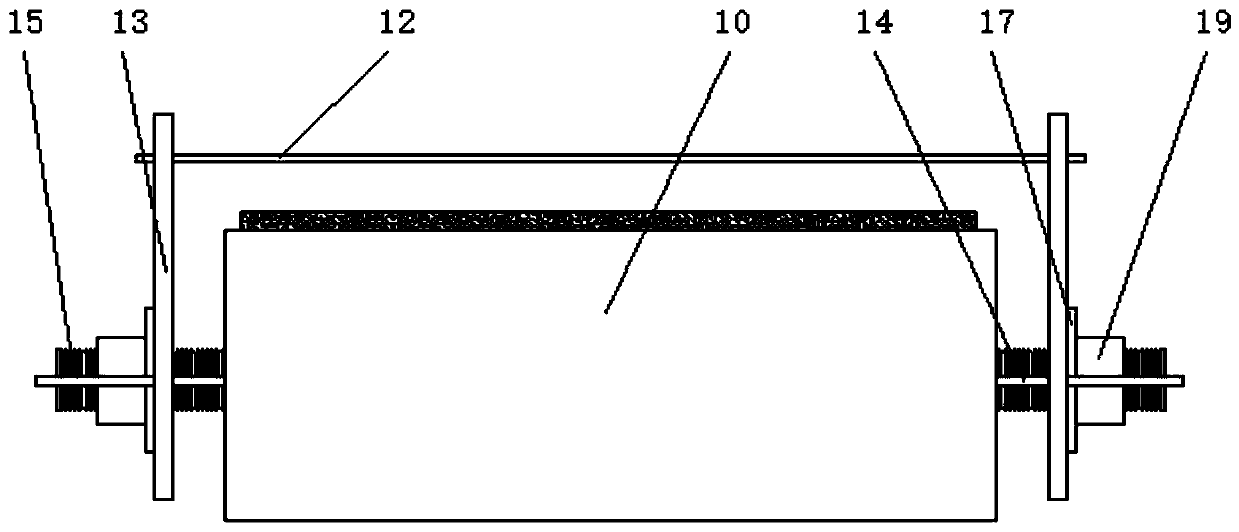

[0022] see Figure 1 to Figure 4 , the present invention provides a technical solution: a continuous cutting device for copper clad laminate processing, including a workbench 1, a drive frame 10 is symmetrically fixed on the upper surface of the workbench 1, a drive roller is arranged inside the drive frame 10, and the drive frame 10 The outer wall of one end is symmetrically fixed with a screw 15, and the surface of the screw 15 is connected with an inner ring 19 through threads. Through the designed inner ring 19, the inner ring 19 can be threaded on the surface of the screw 15, and then the position of the limiting plate 13 is adjusted and fixed. , so that the present invention is applicable to the cutting limit of copper clad laminates of different widths. The outer ring 17 is sleeved on the outside of the inner ring 19. Through the designed outer ring 17, the outer ring 17 is sleeved on the surface of the inner ring 19, thereby ensuring When the inner ring 19 is closed, i...

Embodiment 2

[0024] see Figure 1 to Figure 4 , the present invention provides a technical solution: a continuous cutting device for copper clad laminate processing, including a workbench 1, a drive frame 10 is symmetrically fixed on the upper surface of the workbench 1, a drive roller is arranged inside the drive frame 10, and the drive frame 10 The outer wall of one end is symmetrically fixed with a screw 15, and the surface of the screw 15 is connected with an inner ring 19 through threads. Through the designed inner ring 19, the inner ring 19 can be threaded on the surface of the screw 15, and then the position of the limiting plate 13 is adjusted and fixed. , so that the present invention is applicable to the cutting limit of copper clad laminates of different widths. The outer ring 17 is sleeved on the outside of the inner ring 19. Through the designed outer ring 17, the outer ring 17 is sleeved on the surface of the inner ring 19, thereby ensuring When the inner ring 19 is closed, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com