Fiber cable installation auxiliary equipment

An installation aid and cable technology, which is applied in the field of optical fiber cable installation auxiliary equipment, can solve problems such as easy displacement or dumping, optical fiber entanglement, and inability to conveniently and stably fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

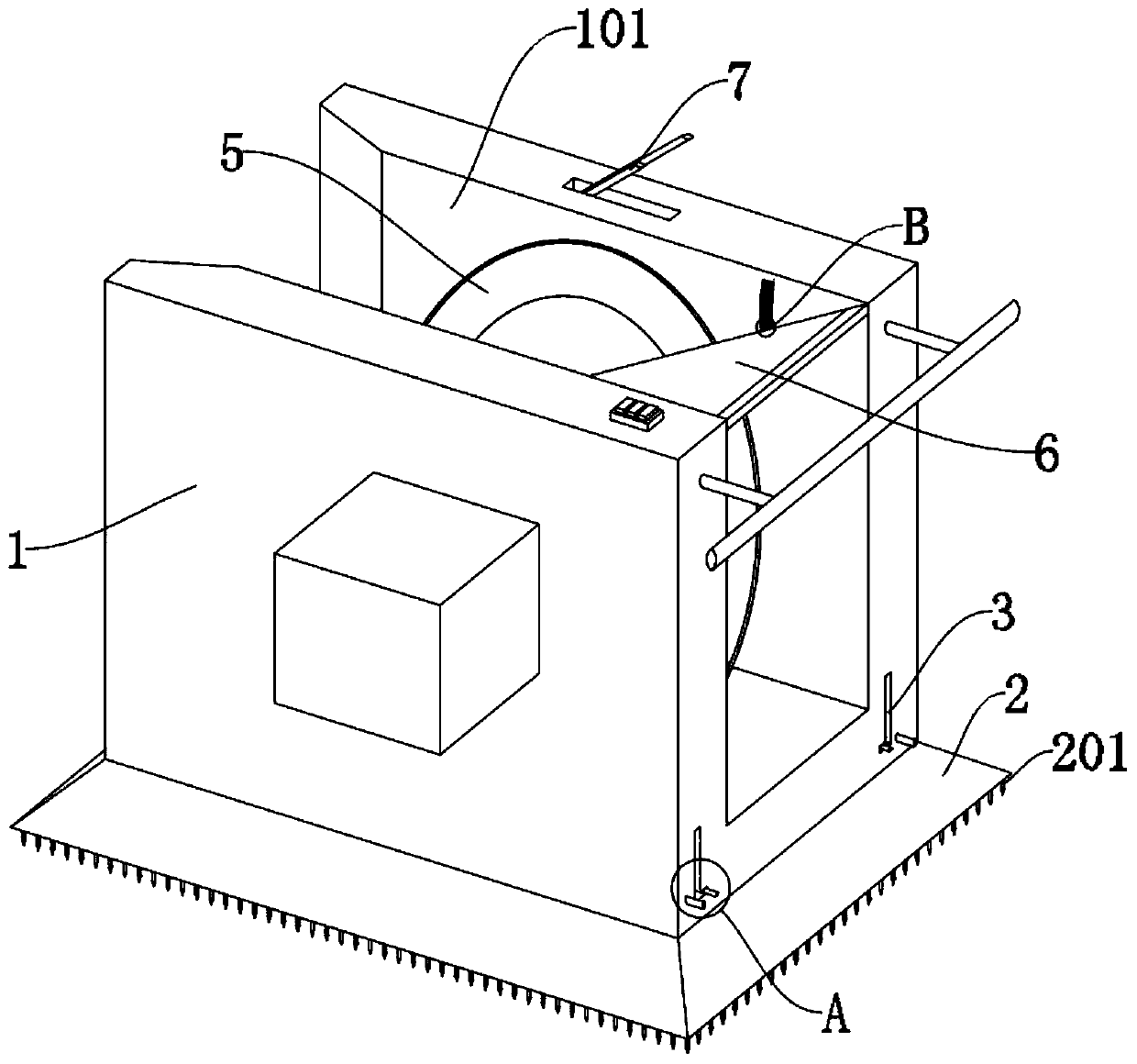

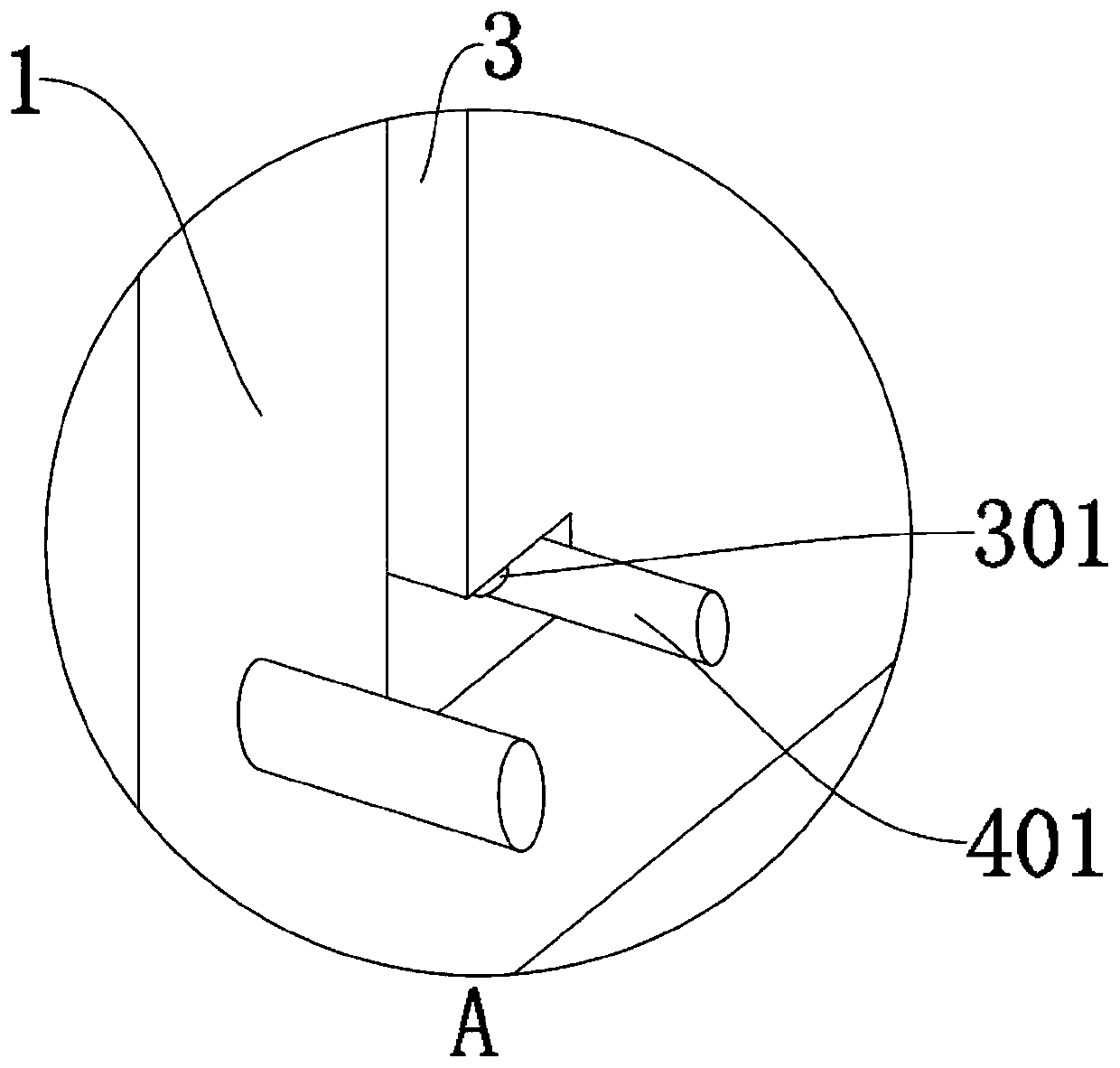

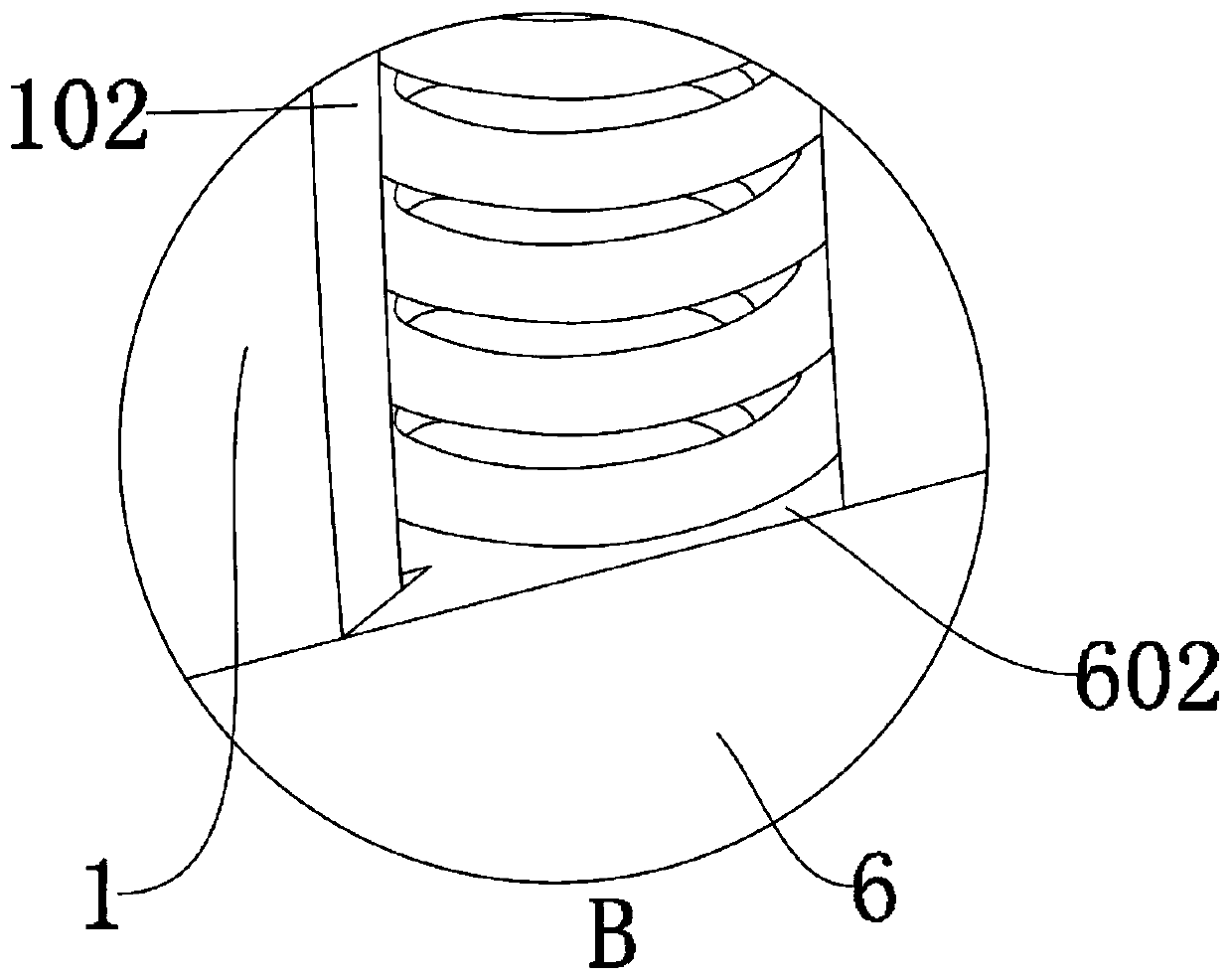

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033]The present invention provides an auxiliary device for installing optical fiber cables, which includes: a main body 1, a side piece 2, a guide groove 3, a moving rod 4, a winding piece 5, a lower pressing plate 6 and a flipping rod 7; the main body 1 has a rectangular structure, and The inside of the main body 1 is equipped with a power motor; the inner side of the side piece 2 is connected to the bottom outside of the main body 1 through a fixed connection, and the side groove 102 is used to install the force-bearing member 602, so that the force-bearing member 602 can be in the Its interior receives the power of the spring and moves downward, so that the lower pressing plate 6 can always press the optical fiber, and the bottom part 201 at the bottom of the side part 2 is used to insert into the ground, so that when the device is used outdoors, The bottom part 201 can be stably inserted into the ground, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com