Independent electroplating device and process for metal workpiece

An electroplating device and electroplating process technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of inapplicability, inability to independently monitor the electroplating process of hardware workpiece products, and the difficulty in achieving the ideal effect of electroplating of hardware workpieces, etc., to meet the application requirements Demand, the effect of improving the quality of electroplating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

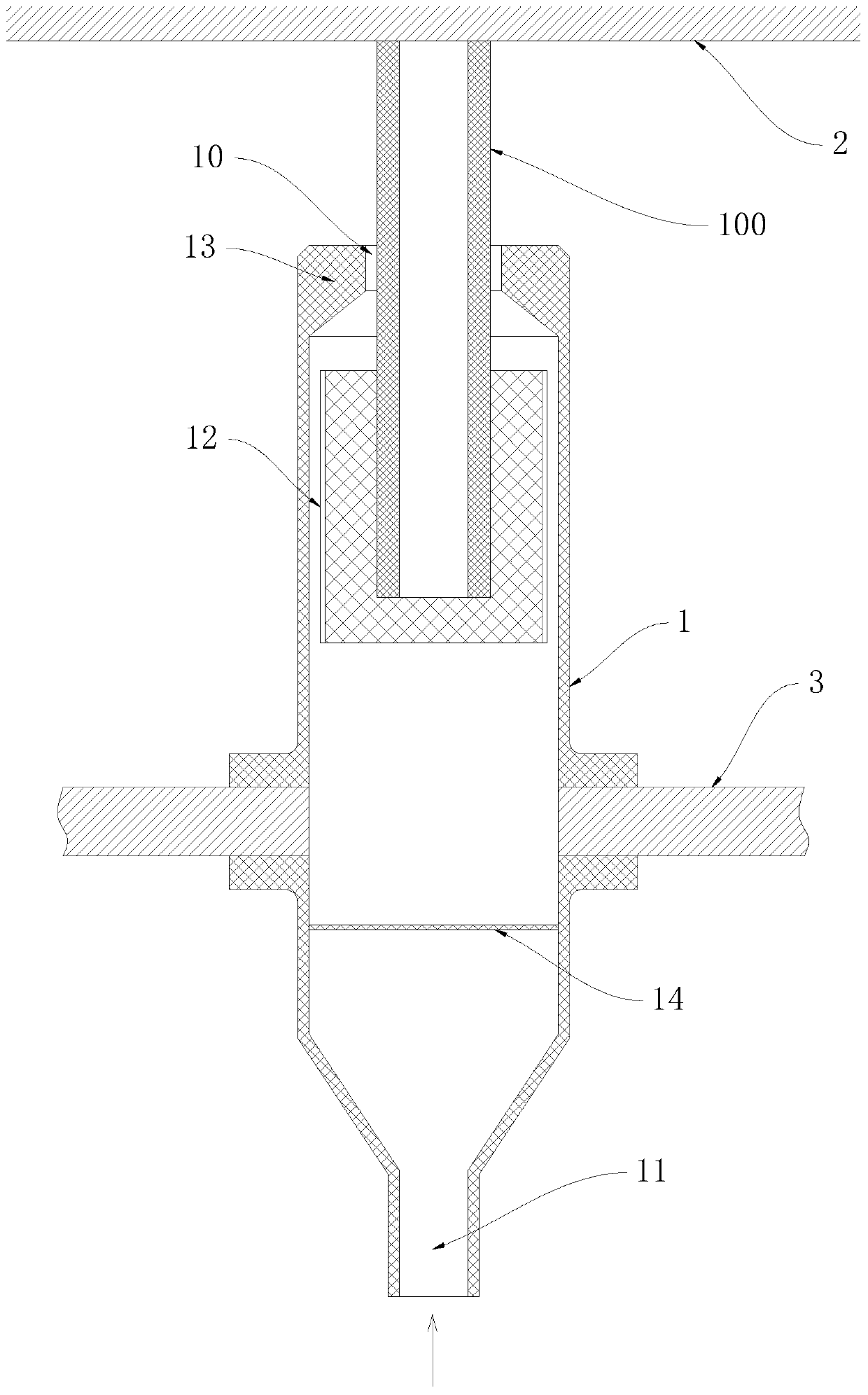

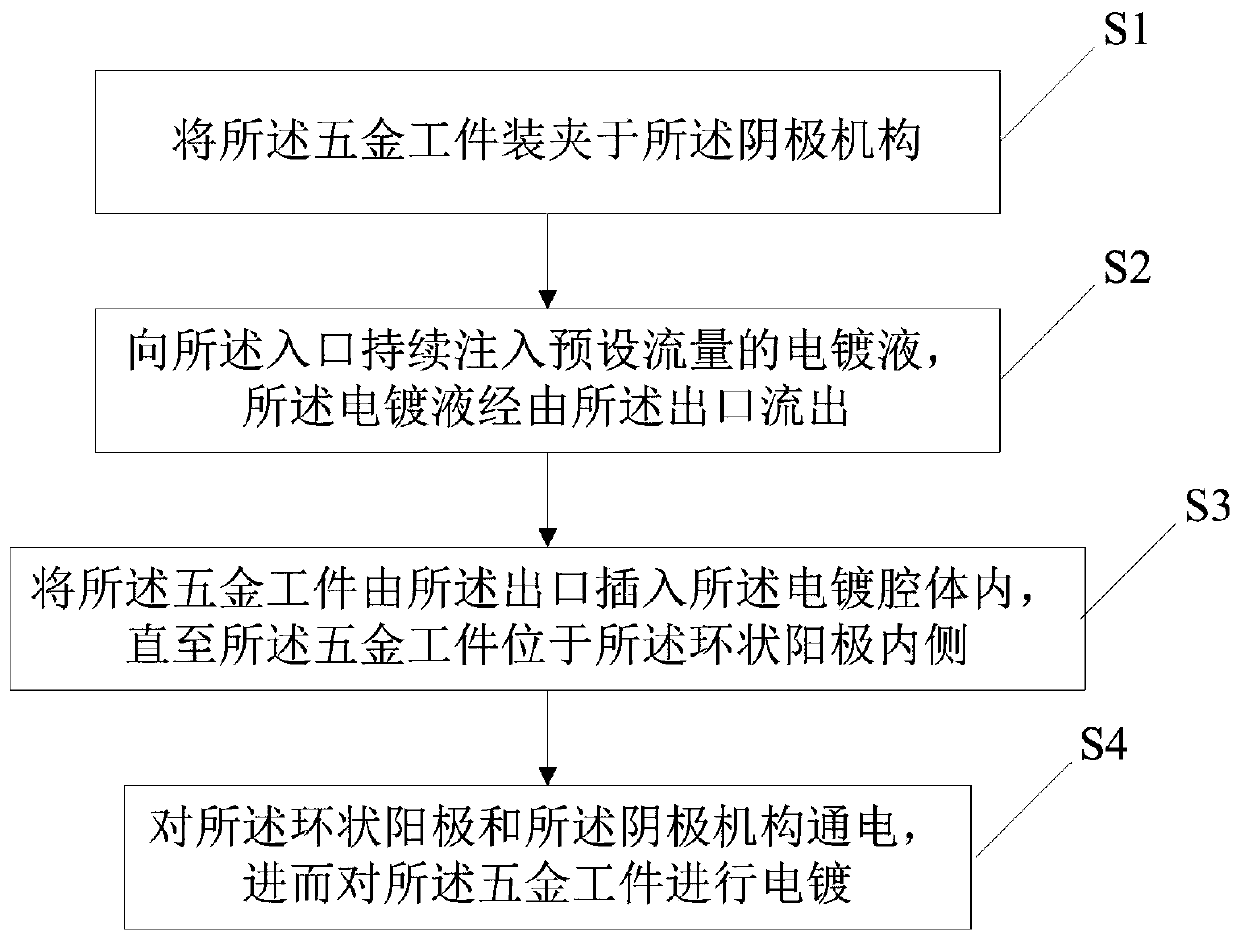

[0019] The invention discloses an independent electroplating device for hardware workpieces, please refer to figure 1 , which includes an electroplating chamber 1, the top of the electroplating chamber 1 is provided with an outlet 10 for the hardware workpiece 100 to pass through, and the bottom of the electroplating chamber 1 is provided with a hole for injecting a predetermined flow rate of electroplating solution Entrance 11, an annular anode 12 is provided in the electroplating chamber 1, and a cathode mechanism 2 for clamping the hardware workpiece 100 is provided above the electroplating chamber 1. During electroplating, the hardware workpiece 100 is The outlet 10 is inserted into the electroplating cavity 1, and the hardware workpiece 100 is placed in the ring-shaped anode 12, and the ring-shaped anode 12 and the cathode mechanism 2 are en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com