Vertical automatic PCB inserting device and method

A technology of PCB board and plug-in device, which is applied in the field of vertical automatic plug-in device of PCB board, can solve the problems of chaotic process management, labor-intensive, manual plug-in errors, etc., so as to improve the quality of electroplating processing, improve production efficiency, reduce The effect of error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

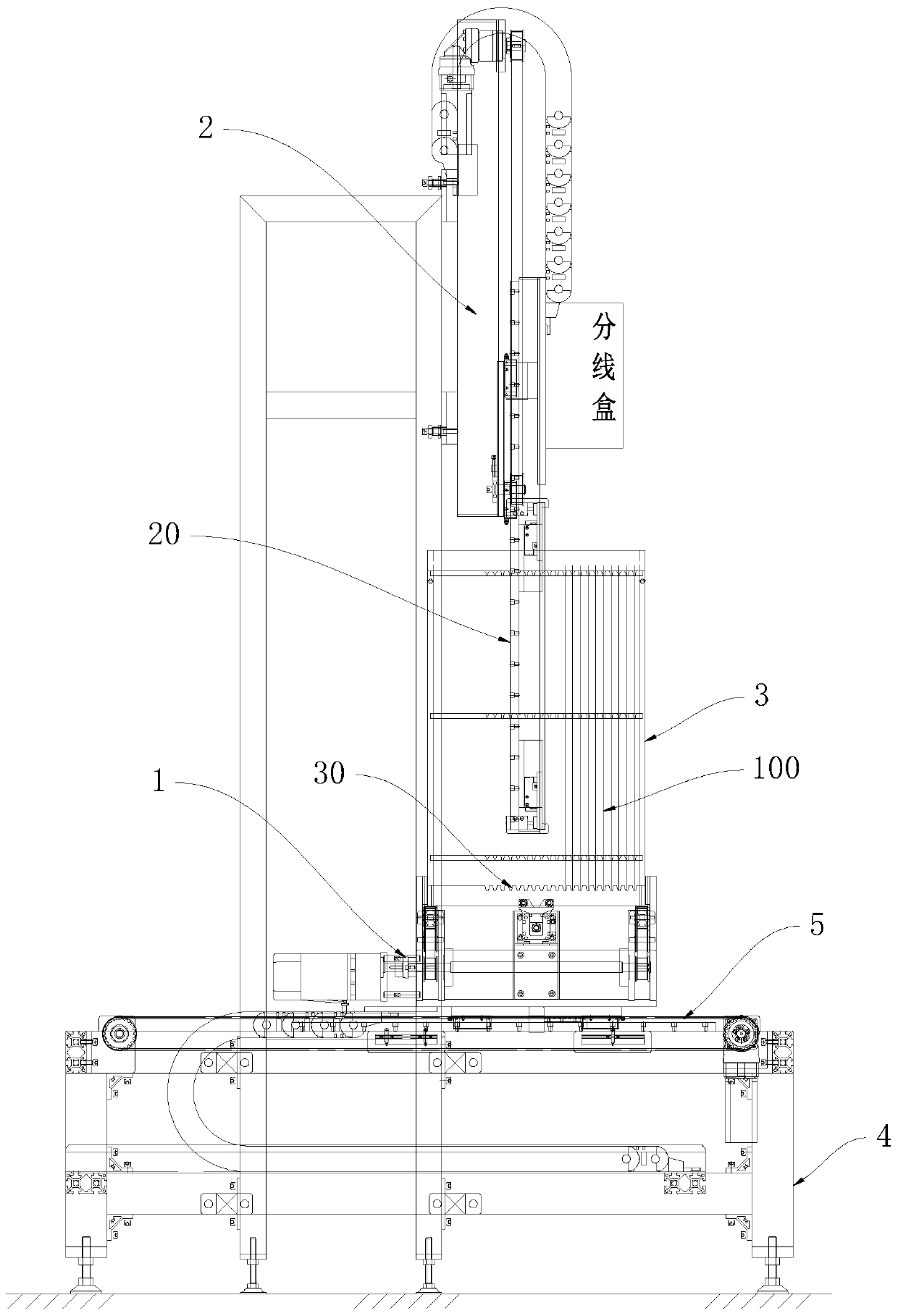

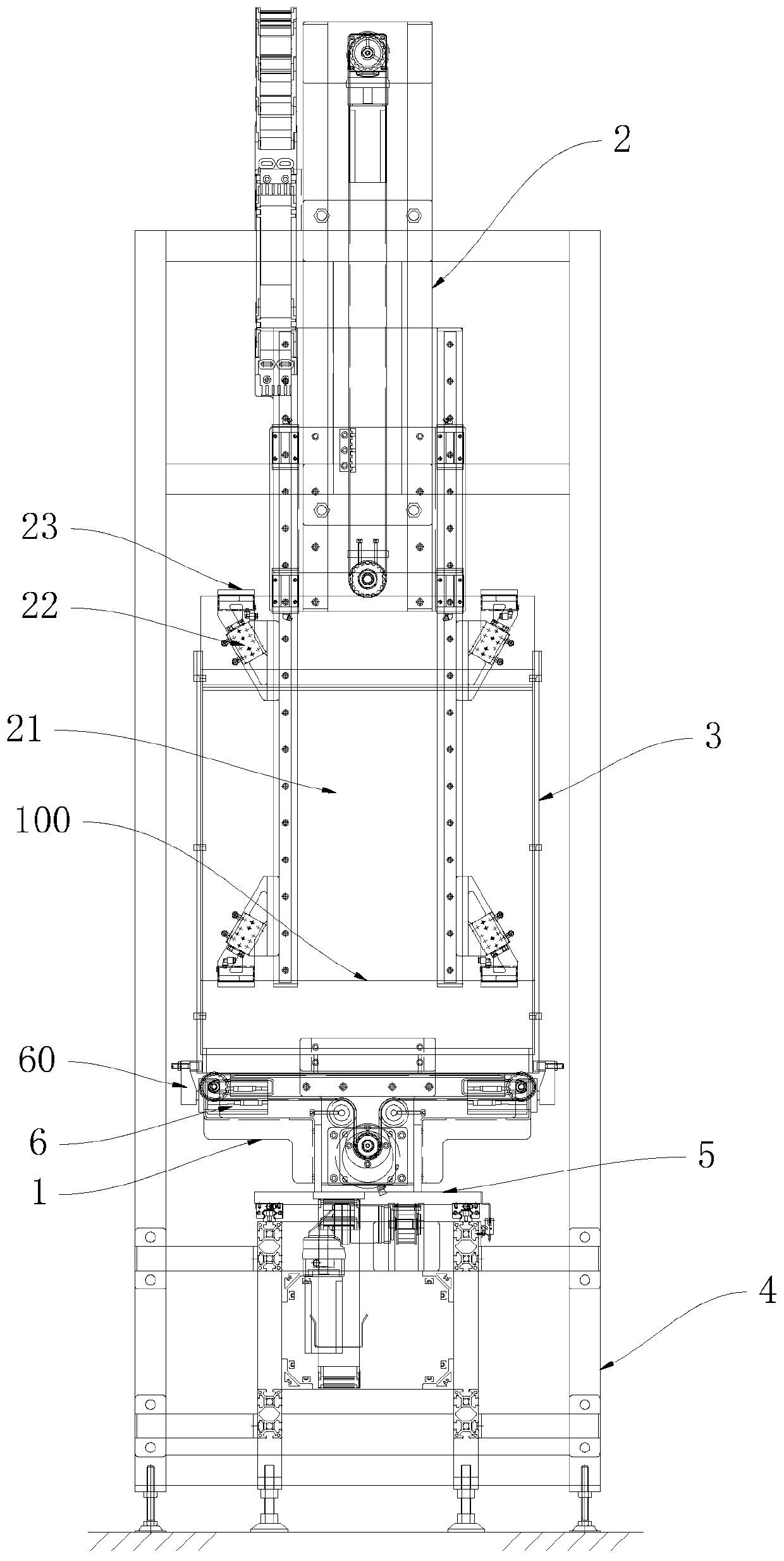

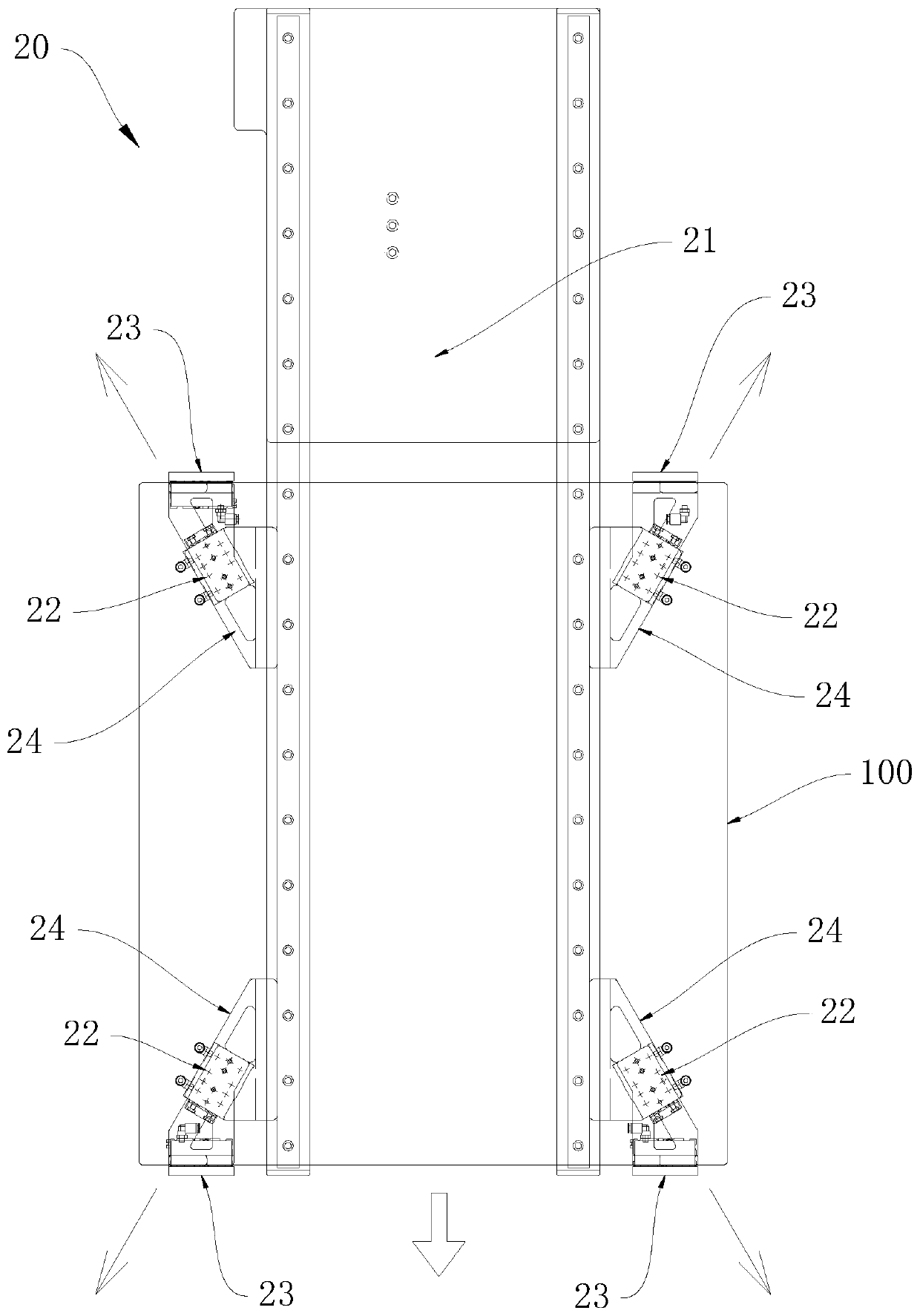

[0020] The invention discloses a PCB board vertical automatic board insertion device, which combines Figure 1 to Figure 3 As shown, it includes a translation mechanism 1 and a lifting mechanism 2. A hanging basket 3 is placed on the translation mechanism 1, and a plurality of slots for inserting PCB boards 100 are provided in the hanging basket 3 from front to back. 30, the hanging basket 3 is driven to translate gradually by the translation mechanism 1, and the distance of each translation step of the hanging basket 3 is the same as the distance between the two slots 30, and the lifting mechanism 2 is provided with a The manipulator 20 grabbing the PCB board 100 , the lifting mechanism 2 is used to drive the manipulator 20 to rise or fall, and the PCB board 100 is inserted into the slot 30 by the manipulator 20 .

[0021] The above-mentioned d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com