Electroplating process for irregular metal workpiece

A technology for metal workpieces and electroplating processes, applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems affecting the combination of coatings and workpieces, the removal of grease and organic debris on the surface of workpieces, and the impact The quality of workpiece electroplating processing and other issues can be improved to improve the effect of pre-treatment and improve the quality of electroplating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

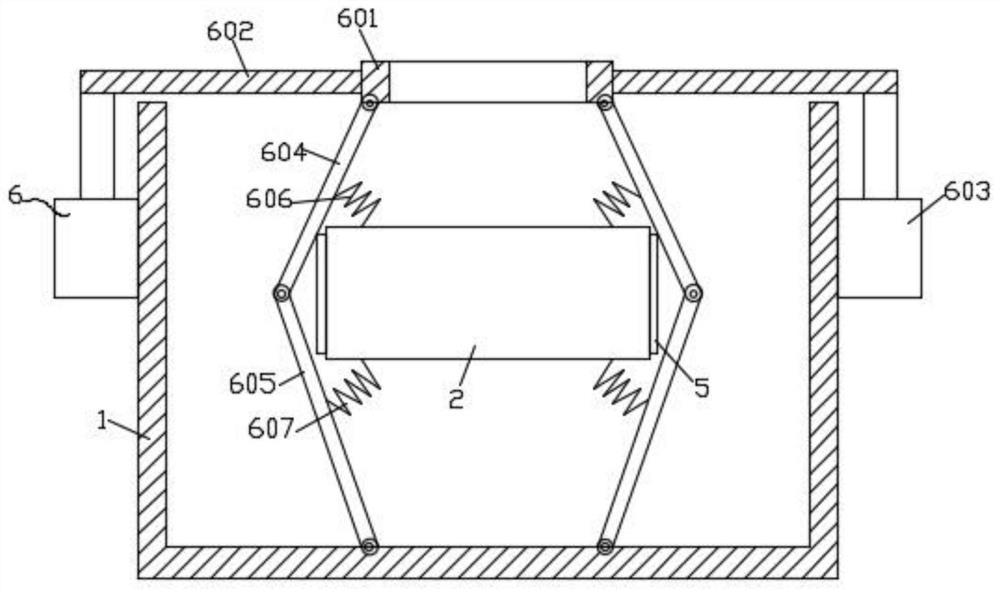

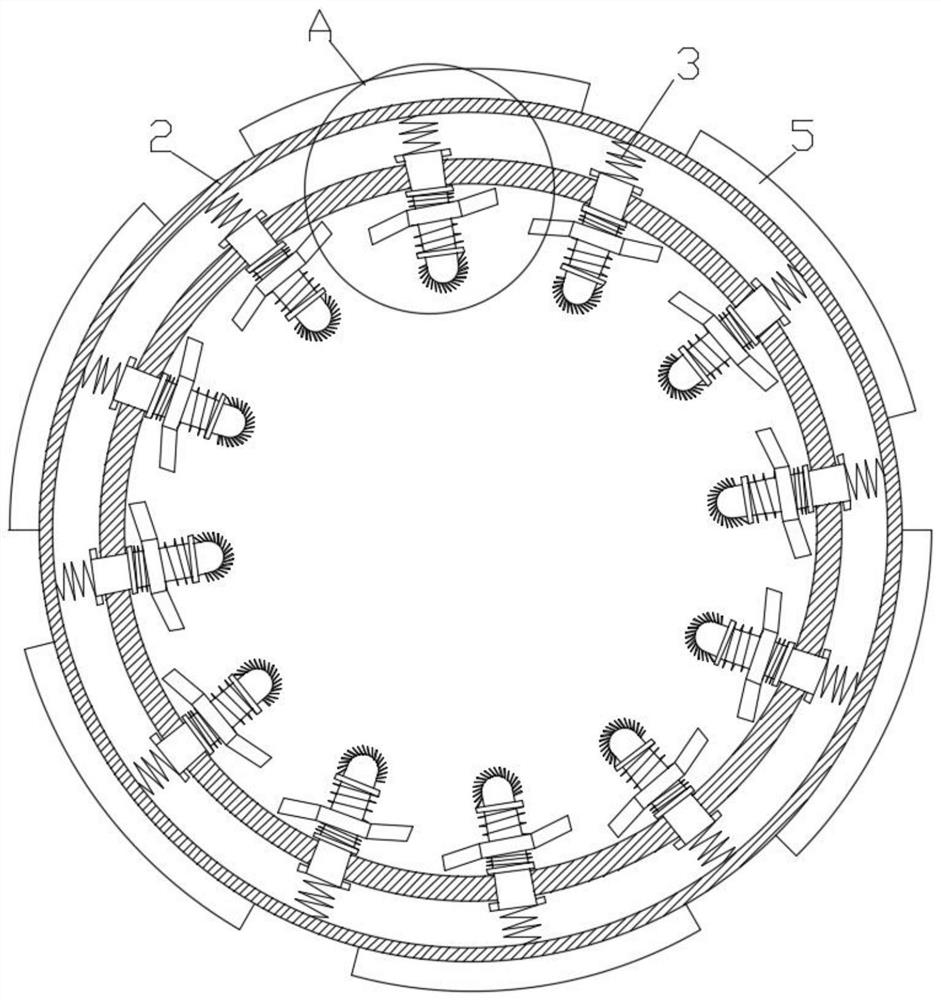

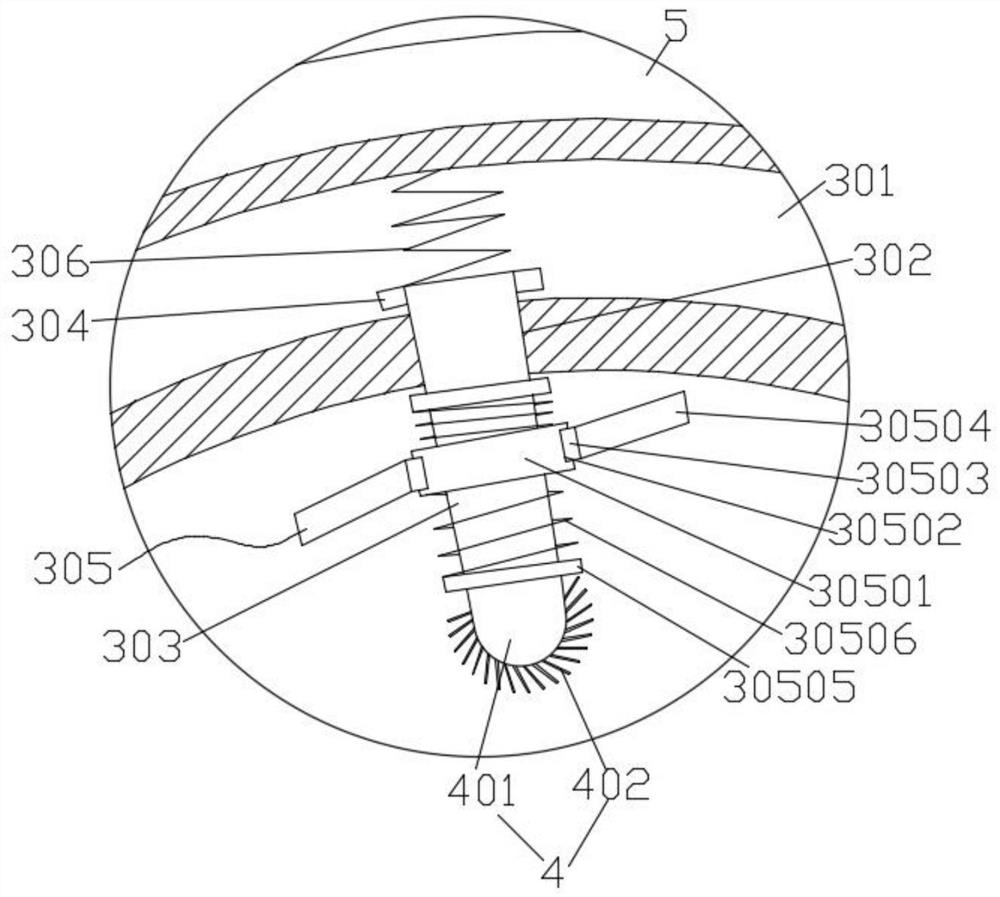

[0023] An embodiment, an electroplating process for irregular metal workpieces, is characterized in that: comprising the following steps,

[0024] In the degreasing step, the metal workpiece is degreased by using the degreasing device, and then cleaned to complete the production of the primary metal workpiece;

[0025] Activation step, soaking the primary metal workpiece in an activation tank, and then washing with water to complete the production of the activated metal workpiece;

[0026] An electroplating step, electroplating the activated metal workpiece to complete the production of the electroplated metal workpiece;

[0027] In the drying step, passivation treatment is performed on the electroplated metal workpiece, and then water washing and drying treatment are performed to complete the production of the finished product.

[0028] In the degreasing step, the degreased metal workpiece is sent into the steam tank, and at the same time, the steam nozzle is activated to sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com