Steel structure for prefabricated building and assembly method thereof

A technology for steel structures and buildings, applied in building structures, buildings, etc., can solve the problems that a set of steel structures is not suitable for buildings of different sizes, and the installation and disassembly of steel structures are cumbersome, etc., to achieve high assembly efficiency, convenient transportation, large Effects of vertical bearing capacity and horizontal deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

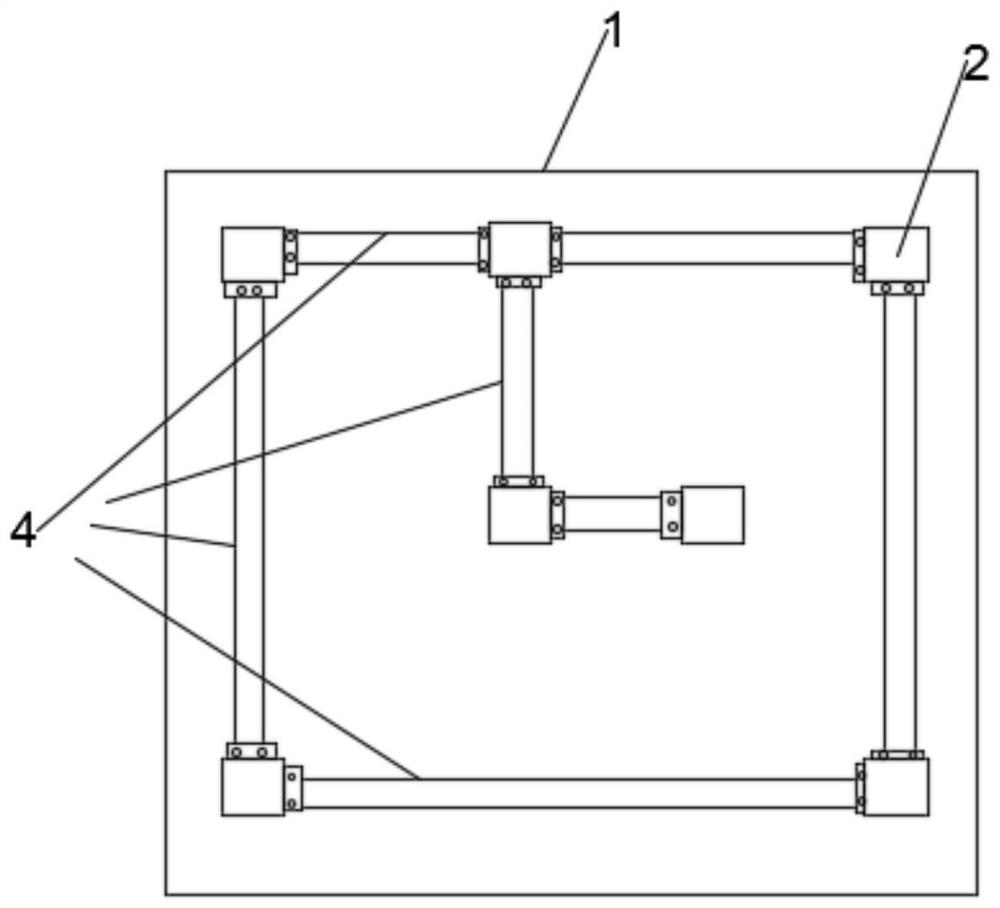

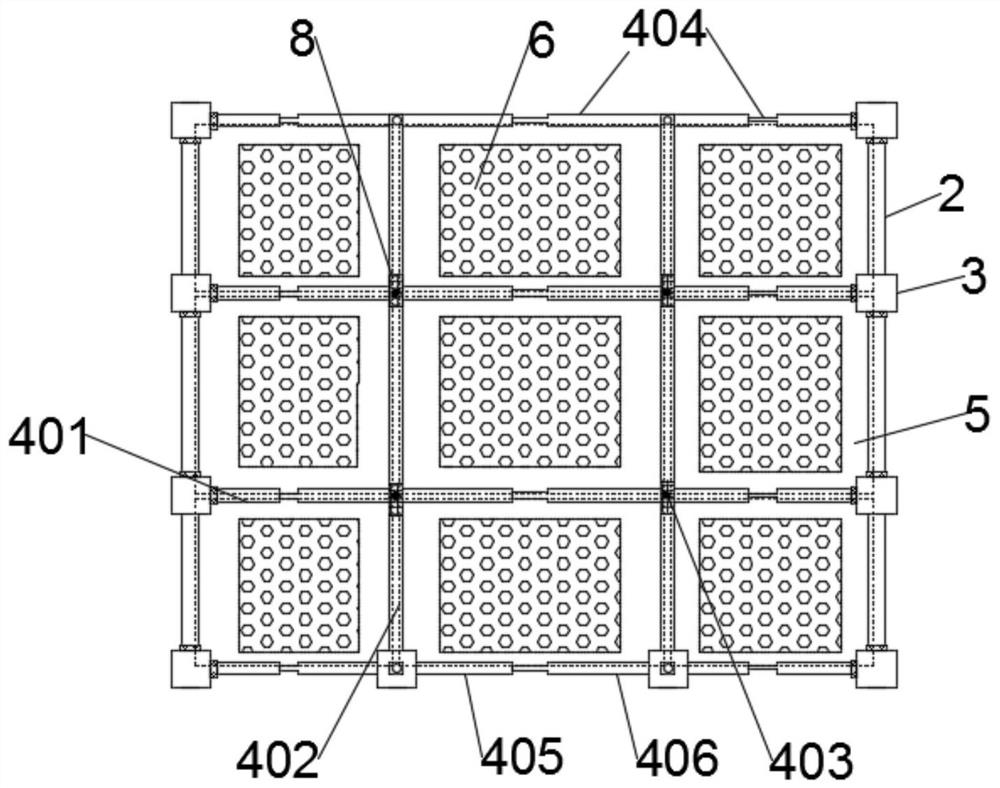

[0051] The building steel structure includes a plurality of corner prefabricated steel columns 2 vertically connected to the bottom plate 1, and the corner prefabricated steel columns 2 are provided with a plurality of splicing joints 3 protruding laterally and horizontally. The splicing head 3 has multiple installation heads (not shown in the figure), more commonly two or three installation heads, so as to complete the installation and splicing of multiple angles. In addition, the angle between two adjacent installation heads on the splicing head 3 can be adjusted so as to meet the needs of assembling irregular steel structures.

[0052] A plurality of splicing joints 3 are distributed at intervals along the height of the corner prefabricated steel columns 2 . And the splicing joints 3 opposite to the two adjacent corner prefabricated steel columns 2 face each other. The corner prefabricated steel columns 2 constitute the outer frame structure defining the corners of the pre...

Embodiment approach

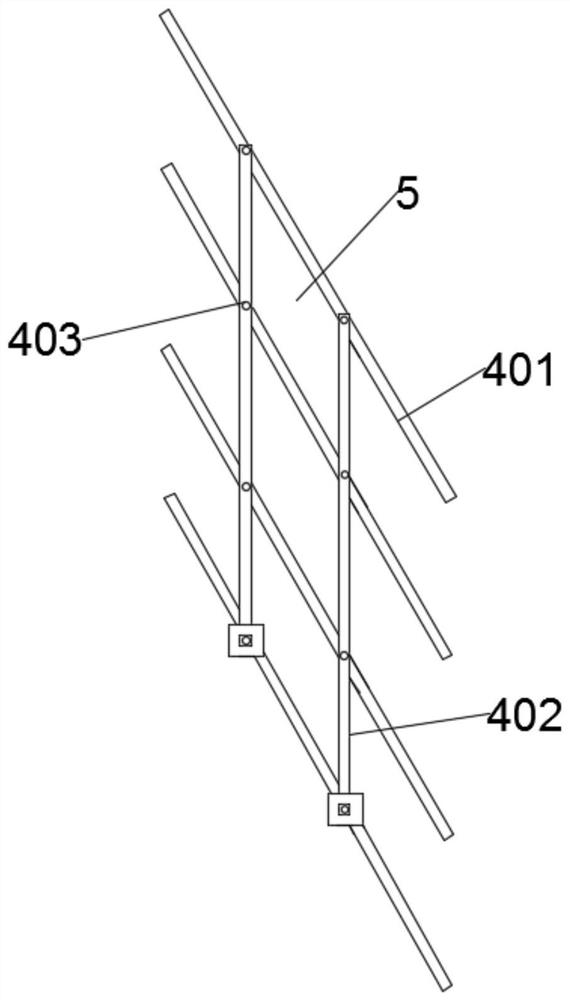

[0062] As a preferred embodiment: the vertical limit assembly 8 includes a limit slider 801 that is arranged on the vertical steel column 402 and can slide along the length direction of the vertical steel column 402, and the limit slider 801 is provided with a limit guide groove 802 , the assembling cross bar 407 is provided with a limit guide strip 803 perpendicular to the extending direction of the assembling cross bar 407 , and the limit guide bar 803 can be set inside the limit guide groove 802 .

[0063] After the horizontal steel column assembly 401 and the vertical steel column 402 are adjusted to be perpendicular to each other, the limit guide groove 802 on the limit slider 801 and the limit guide bar 803 are located on the same straight line. Push the limit slider 801, engage the limit guide bar 803 inside the limit guide groove 802, and the vertical relationship between the horizontal steel column assembly 401 and the vertical steel column 402 will be locked.

[0064...

Embodiment 2

[0068] Such as Figure 8 As shown, a method for assembling a steel structure for a prefabricated building comprises the following steps:

[0069] S100: Outer frame installation: first set up the base plate, and install the corner prefabricated steel columns at the turning corners of the steel structure on the base plate, and the corner prefabricated steel columns form the outer frame of the steel structure and the internal partition frame;

[0070] S200: Wall frame installation: Install the prefabricated wall support components that can be folded and stretched horizontally between two corner prefabricated steel columns to form the inner wall frame and the outer wall frame of the steel structure, and the composition A number of filling lattices are formed between the mutually hinged crossbars of the wall support assembly;

[0071] Specifically, the following steps are included:

[0072] S201. Adjust the mutually hinged vertical and horizontal bars of the wall support assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com