Grinding machine safety operation monitoring protection system

A technology of safe operation and protection system, which is applied in the direction of grinding/polishing safety devices, grinding machine parts, grinding automatic control devices, etc., which can solve the problem that the reliability of electronic products cannot absolutely meet safety protection, long cycle time, and transformation costs High-level problems, to achieve the effect of safety protection for habitual unsafe operating behaviors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

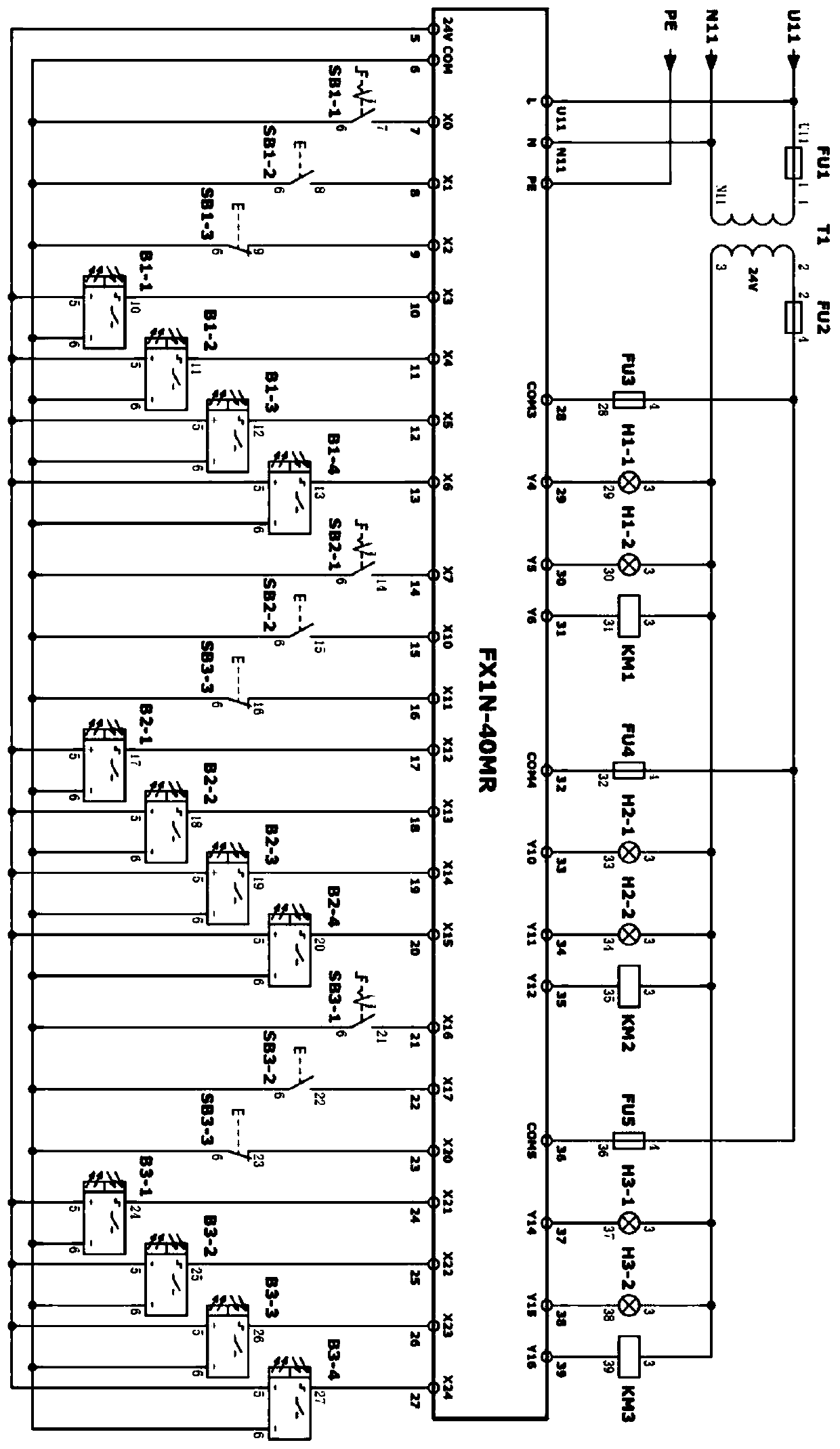

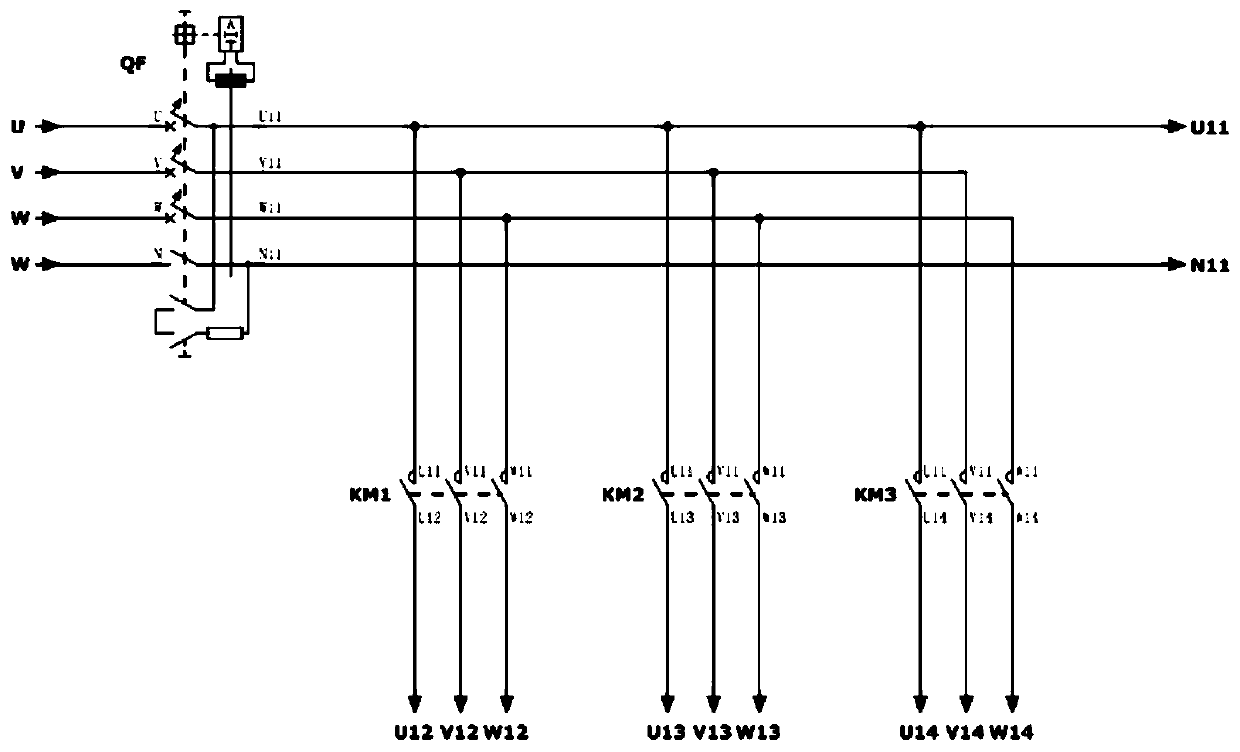

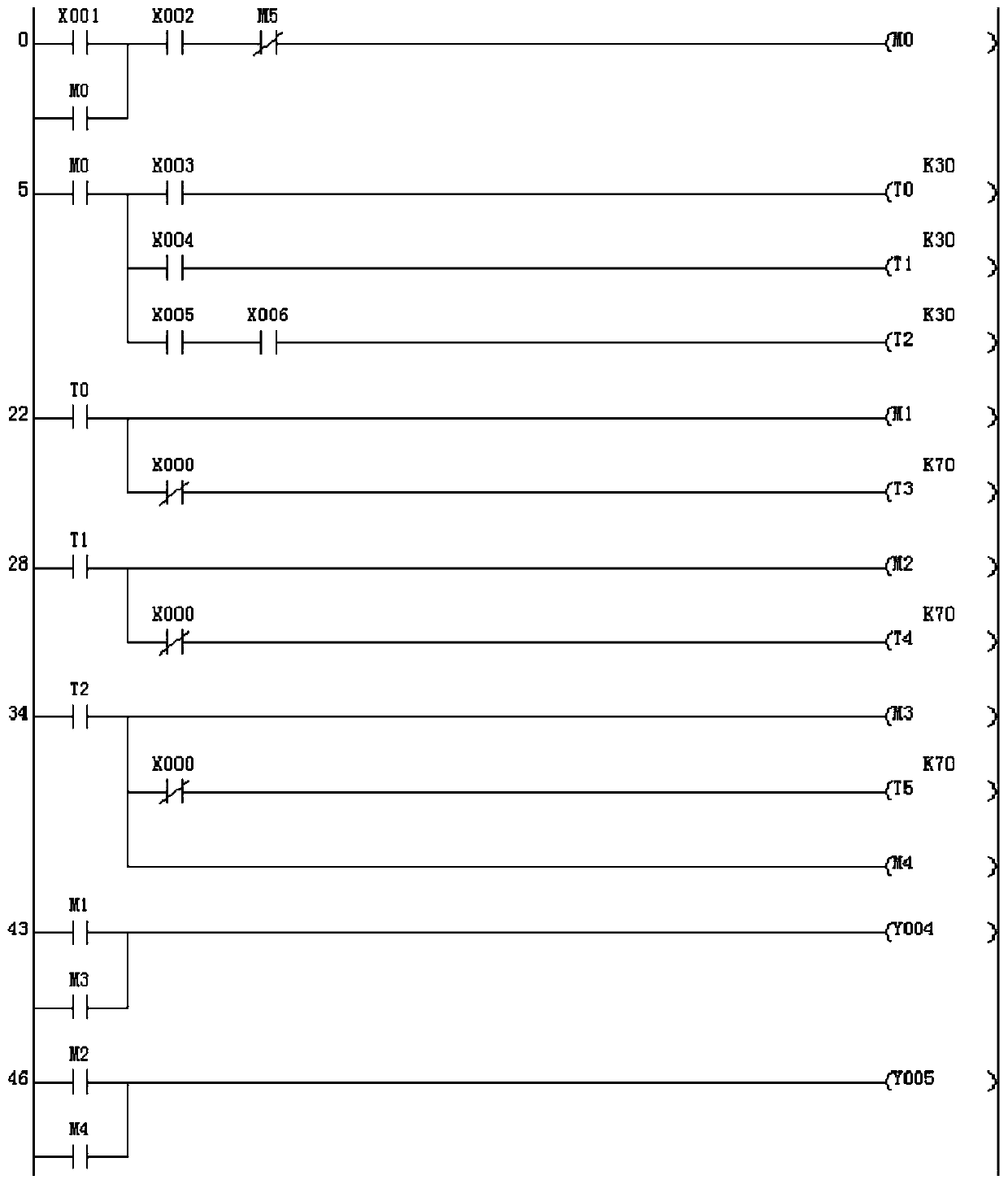

[0024] Example: Taking the habitual illegal operation behavior of a single grinder during operation as an example, four photoelectric sensors are used to monitor the habitual illegal operation of a single grinder during operation, all of which are placed on the front of the grinder XZ On the wall of the axial projection surface, two sensors (No. 1 and No. 2) are placed on the wall 30mm to 50mm above the tangent line of the highest point of the protective cover of the two grinding wheel discs. Human body; the other two sensors (No. 3 and No. 4) are placed on the inner side of the same height as No. 1 and No. 2 sensors, and their function is to detect the human body standing on the side of the grinder. The location of the distribution box depends on the specific working environment, and there are no special requirements. Specific steps:

[0025] This equipment has two states of automatic warning control and prompt alarm warning control:

[0026] 1. Automatic alert control stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com