Multi-angle assembling type reinforcement structure

A prefabricated, multi-angle technology, applied in the direction of building structure, structural elements, building components, etc., can solve problems such as inability to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

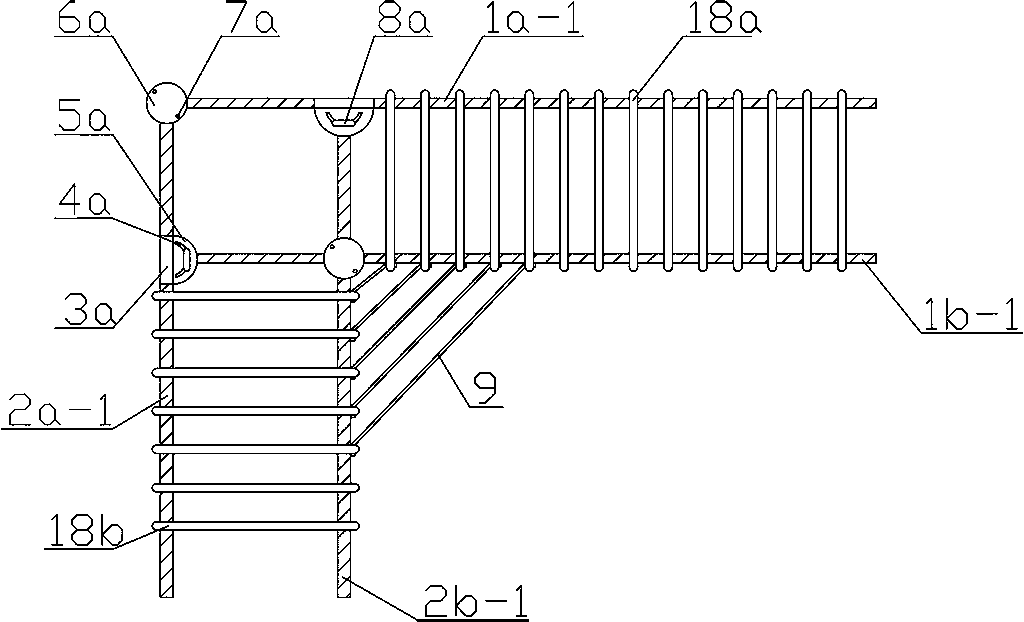

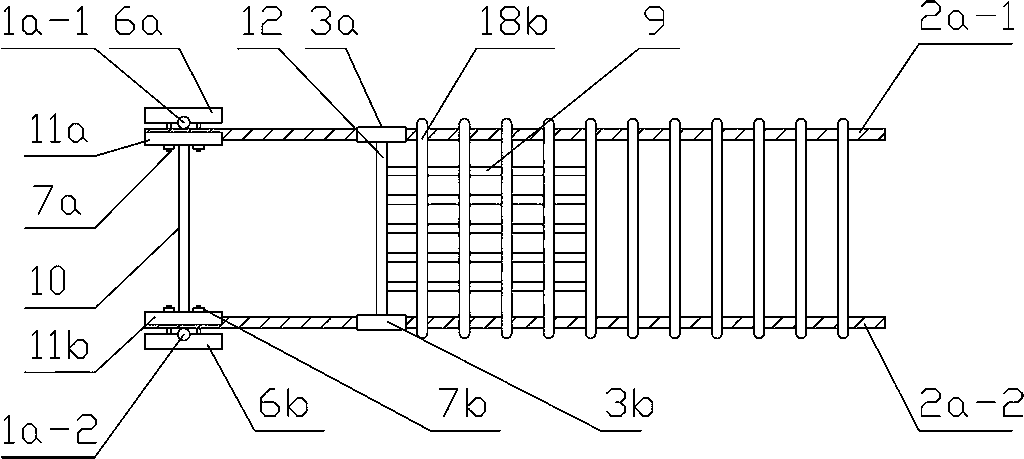

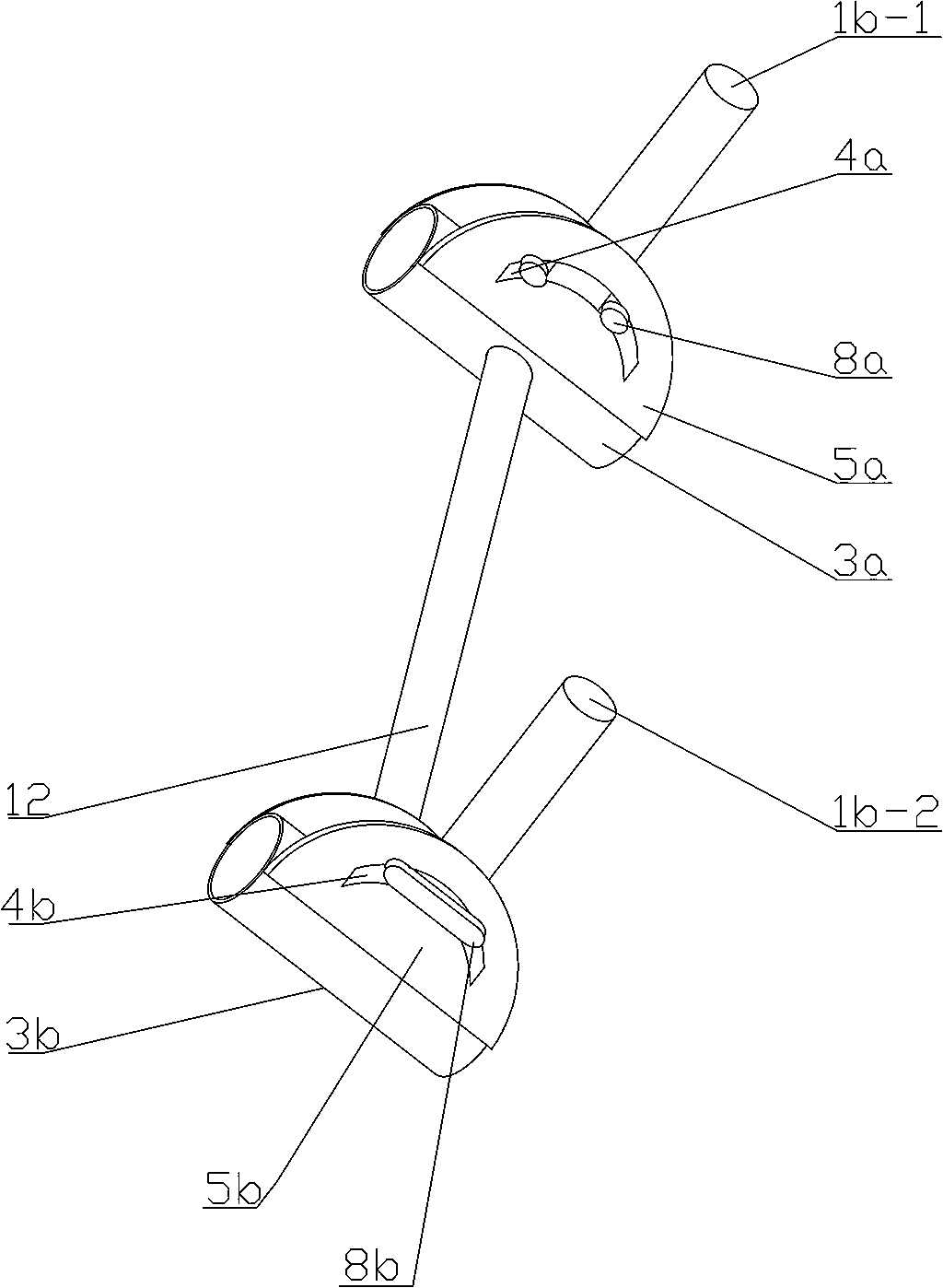

[0029] Such as Figure 1 to Figure 6 As shown, a multi-angle prefabricated reinforcement structure includes a reinforcement skeleton, and the reinforcement skeleton includes a first reinforcement skeleton and a second reinforcement skeleton, the first reinforcement skeleton is a rectangular frame, and includes a first outer erecting bar group, a An inner set of vertical ribs and the first stirrup 18a, the first outer set of vertical ribs and the first inner set of vertical ribs are parallel to each other, and the first stirrup 18a is sleeved with the first outer set of vertical ribs and the first The right end of the inner vertical rib group, the first outer vertical rib group is the first outer upper vertical rib 1a-1 and the first outer lower vertical rib 1a-2 corresponding up and down, and the first inner vertical rib group is the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com