A Subassembly Extraction Method Based on Interference and Connection Relationship

A technology of sub-assembly and connection relationship, applied in the field of sequence planning in precision assembly, can solve problems such as not considering the interference between all parts, achieve high practical value and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

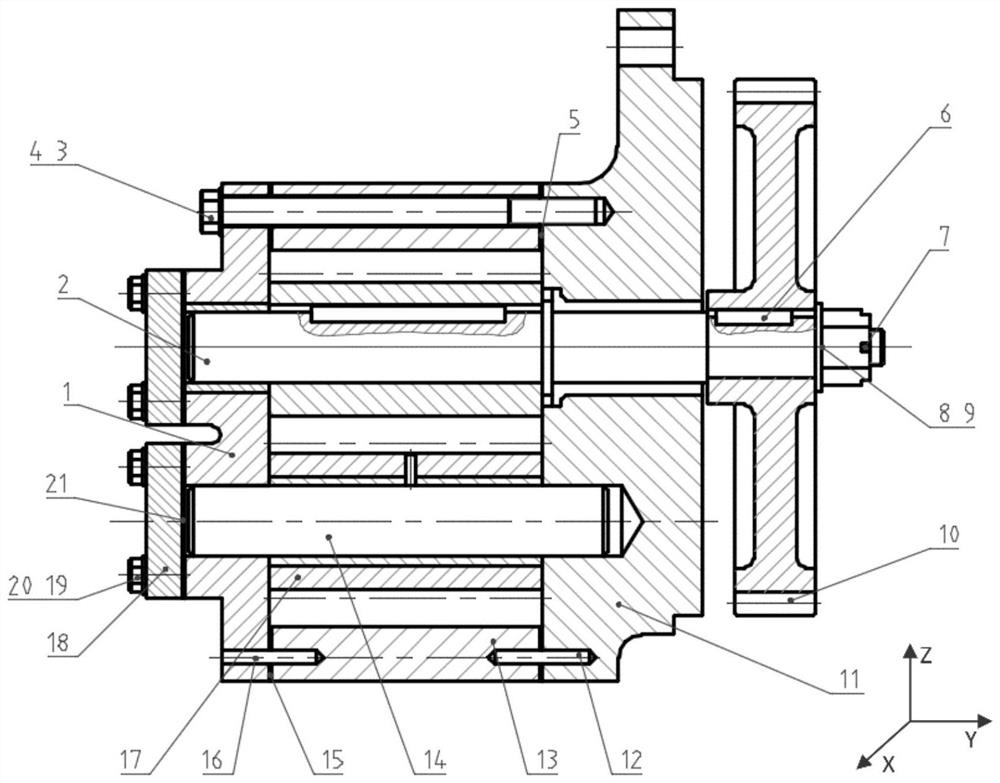

[0035] Taking the extraction of sub-assemblies in diesel engine oil pump sub-components as an example, the specific implementation manner of the present invention will be described in detail in combination with technical solutions and accompanying drawings.

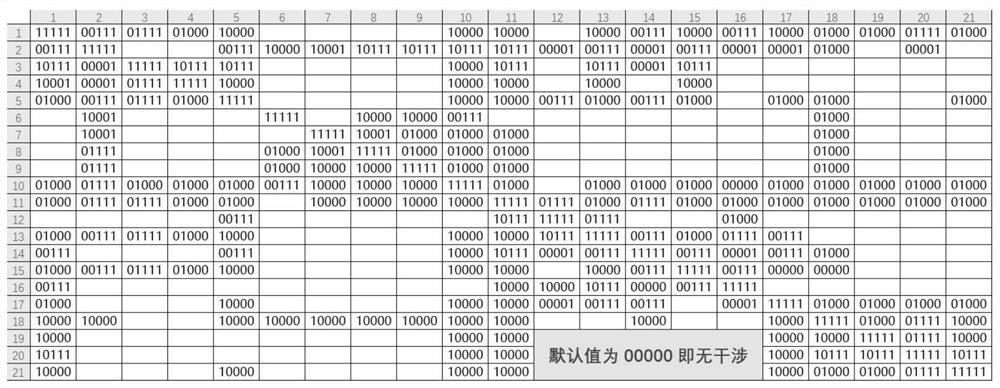

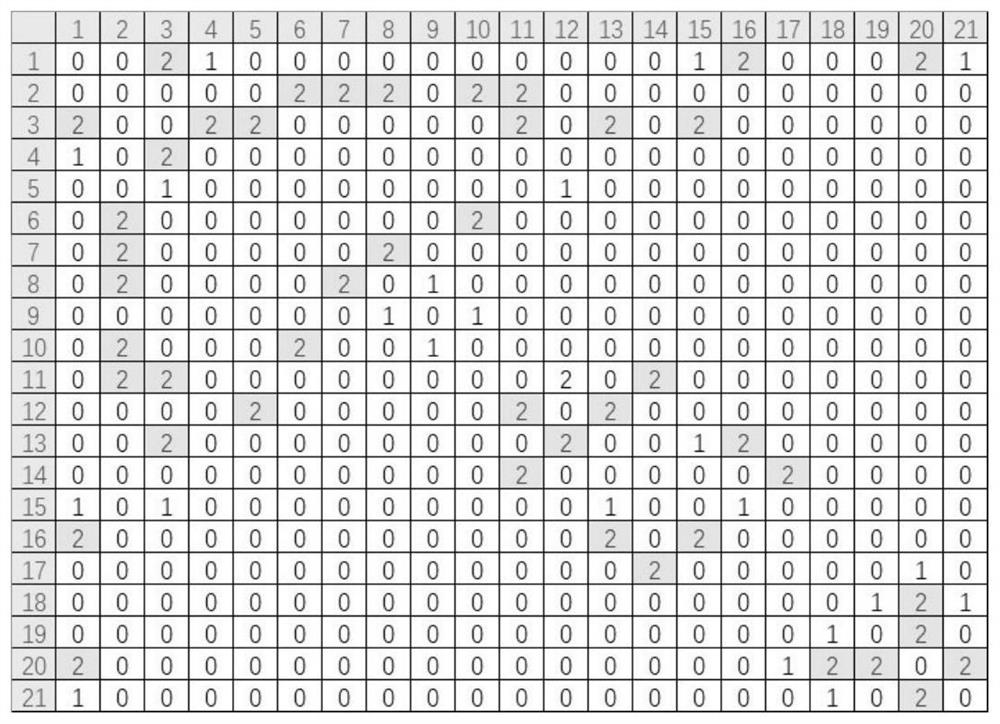

[0036] figure 1 For the diesel engine oil pump sub-components, the interference matrix between parts is established according to the spatial position relationship of the parts in the diesel engine oil pump sub-components ( figure 2 ) and connection matrix ( image 3 , taking the current orientation as the assembly orientation). Select part 11 as the first assembly part, and then analyze the assembly sequence related to part 1. Add part 11 to the pre-assembly part collection of part 1, and find I by traversing the interference matrix 11,1 |I 3,1 =11111, make part 3 a post-assembly part of part 1, and make part 1 a pre-assembly part of part 3. By analogy, after multiple traversals, the sequence relationship between pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com