A high-voltage overhead line and its sagging automatic correction equipment

A high-voltage overhead line and equipment technology, applied in the field of overhead lines, can solve the problems of wire pull loss, affecting the quality of power transmission, sagging, etc., and achieve the effect of avoiding wire loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

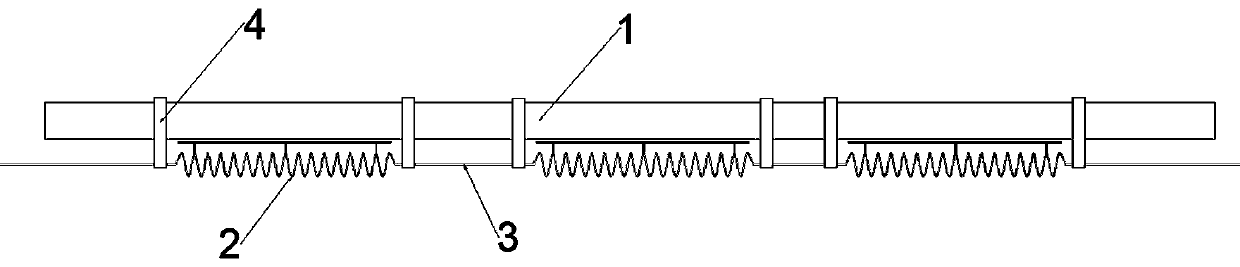

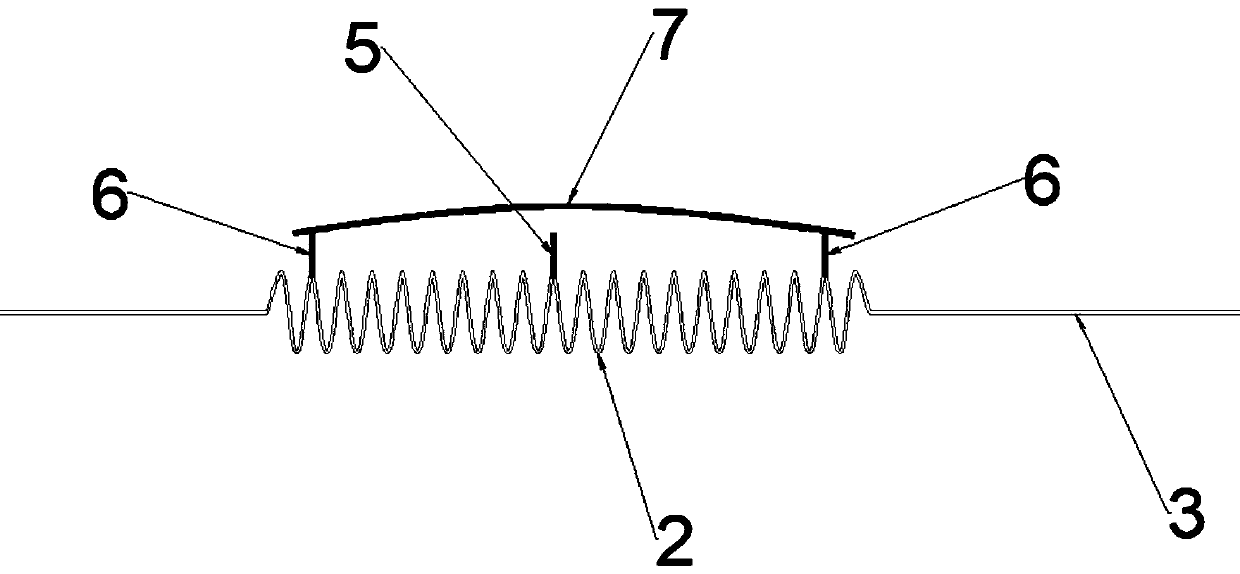

[0027] Such as figure 1 As shown, a high-voltage overhead line includes a conductor body 1 and an adjustment line. The adjustment line is composed of a spring 2 and a steel wire 3 connected in sequence, that is, the adjustment line adopts the form of a section of spring 2-a section of steel wire 3-a section of spring 2... It is equivalent to cutting off a section of steel wire and then adding spring 2. In addition, a whole section of spring 2 can also be used, but it is not suitable for lines with long overhead lines because their elastic range is too large. The conductor body 1 and the adjustment line are erected in parallel between the two towers and heavy hammers are set at both ends. The heavy hammers are set at the initial stage of ere...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap