High-strength G-shaped fastening piece and fastening structure

A fastening and high-strength technology, which is applied to wing parts, door/window accessories, building structures, etc., can solve the problems of entering the room, stress concentration at the stress point, and no sound insulation effect, etc., to achieve firm interlocking effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

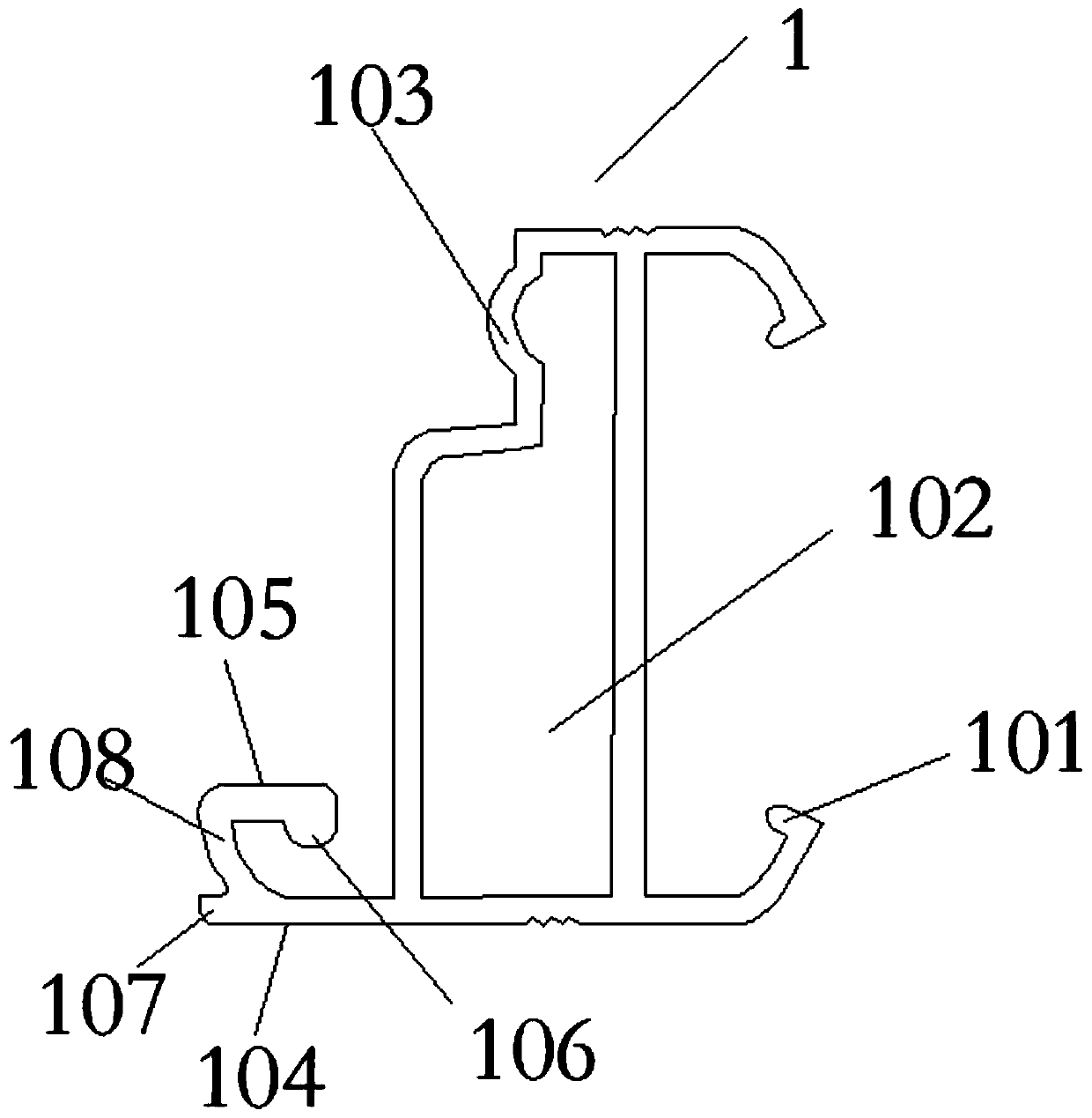

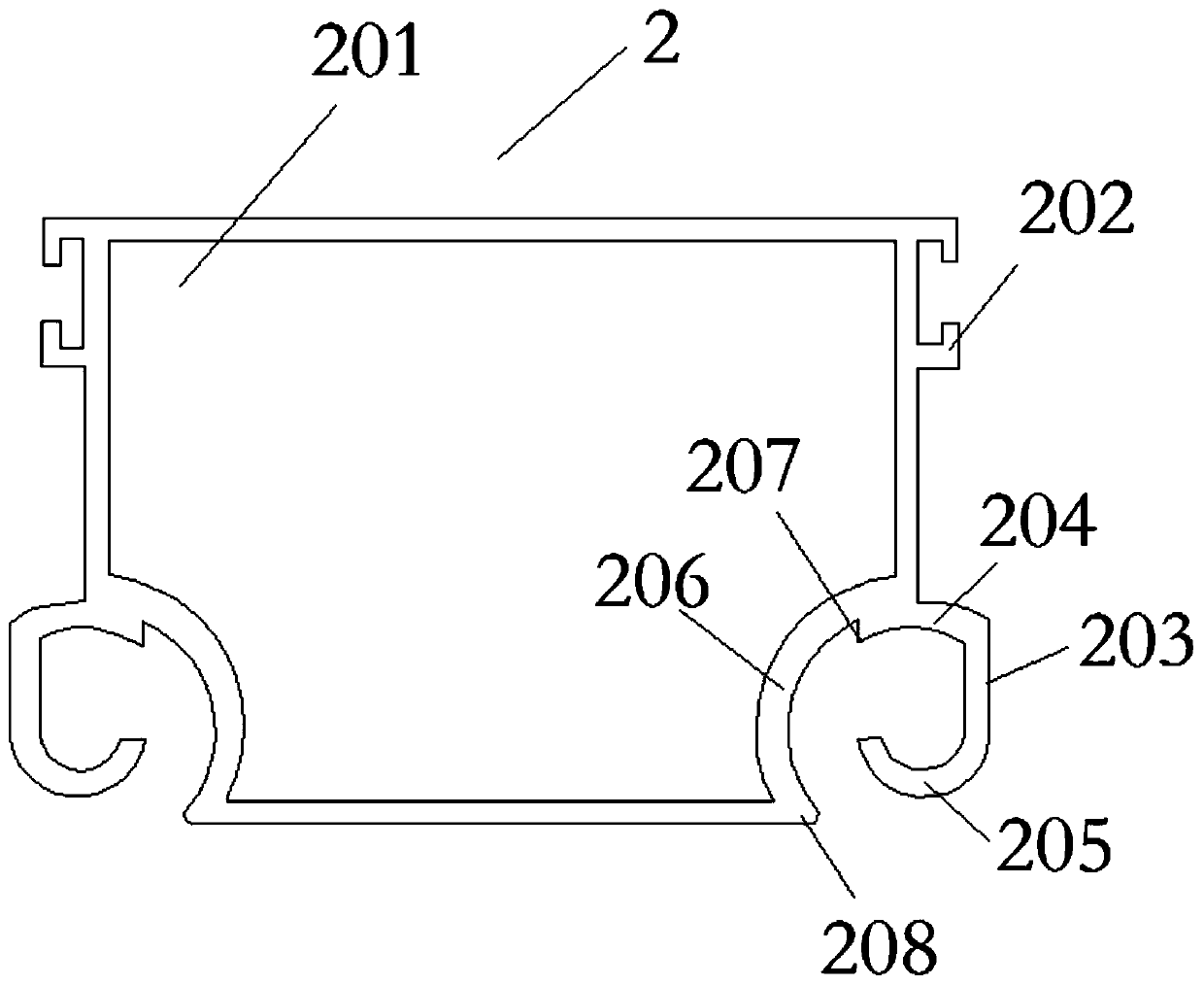

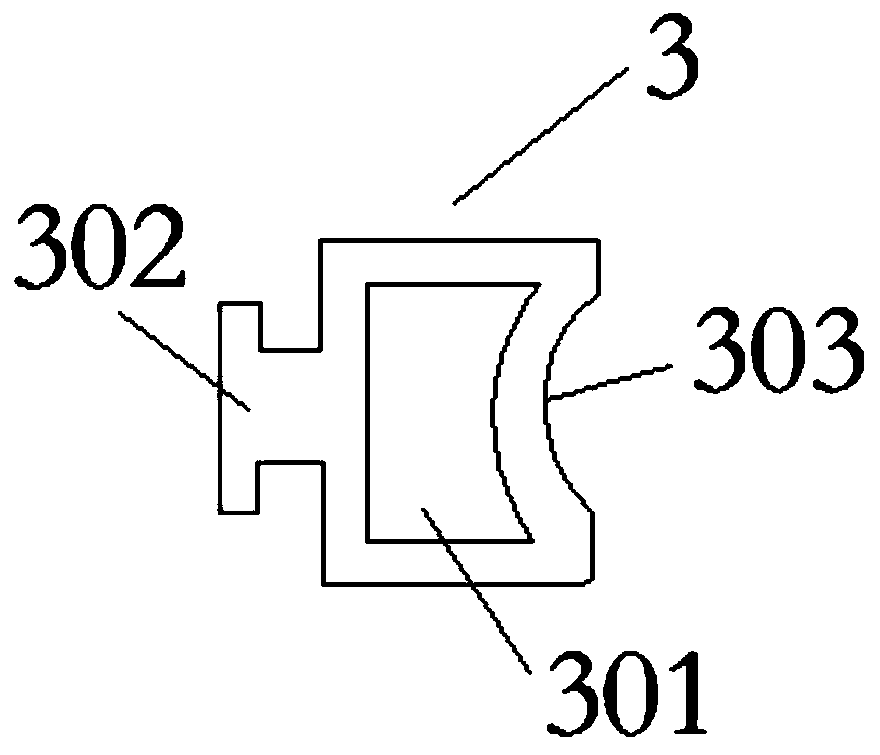

[0024] In order to replace the traditional hinge to achieve the rotational connection between two objects, this embodiment first discloses a high-strength G-shaped fastener that can be fastened to each other. The G-shaped fastener includes figure 1 The overlock fastener 1 shown also includes figure 2 The lock and enterprise buckle 2 shown. Both the lock edge fastener 1 and the lock enterprise fastener 2 are designed to be as long as the connecting surface of the object, so that they can be closely connected with the connecting surface of the object to form an integral body, so that the stress point is not concentrated in the local area, but evenly along the connecting surface Scattered, the structural strength is significantly better than traditional hinges.

[0025] A seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com